Hydraulic systems depend on various parts to create, manage, and guide fluid power smoothly. Two of the most important pieces in these setups are piston pumps and control valves. Together, they make sure hydraulic energy reaches the right spot at the right time.

Piston Pumps

Positive Displacement Principle

Piston pumps are a kind of pump you might pick for your system setup. They fall under the category of positive displacement pumps. These pumps allow almost no leakage compared to the amount of fluid they push out. They operate based on a simple positive displacement idea.

This idea means the pump moves the same quantity of fluid with each turn. Also, the fluid keeps flowing over many cycles because of the tight fit between the pump’s casing and its inner workings.

Variable and Fixed Displacement Configurations

Piston pumps can be set up to give either changing or steady displacement during their cycles. In a changing setup, the output shifts by adjusting how much fluid passes through the chamber. But in a steady setup, the output stays the same since the fluid amount in the chamber doesn’t vary.

Reciprocating Pump Design

Piston pumps are built using the basic rules of a reciprocating pump. This type of pump creates pressure with a piston inside a closed cylinder space that has an entry and exit for fluid.

When the piston pulls back, it sucks fluid into the space. After it’s full, the piston pushes the fluid out through the exit to build pressure.

Cylinders and Pistons Arrangement

In a piston pump, several cylinders and pistons are used instead of just one of each. Often, these pistons and cylinders are placed in a round pattern around a spinning part. They’re driven by linking the spinning case to a driveshaft.

As part of this spinning action, the pump creates back-and-forth motions. The pistons slide up or down in the cylinders to pull in or push out fluid. This process creates both flow and pressure.

Radial Piston Pumps

In radial pump designs, the pistons are set outward within the casing on the cylinder block. When the pump runs, the pistons shift sideways compared to the driveshaft’s center. There are two main styles: one with ball-shaped pistons and another with cylinder-shaped ones.

Radial piston pumps can also be explained by the layout of their openings. Usually, they use either pintle valves or check valves for this.

Axial Piston Pumps

Axial pump designs are a bit different in how they’re placed. Here, the pistons move in line with the driveshaft’s center. This style uses port plates, control valves, or check valves to guide the fluid as it’s pulled in and then pushed out of the pump.

One of the simplest axial designs is the inline piston pump.

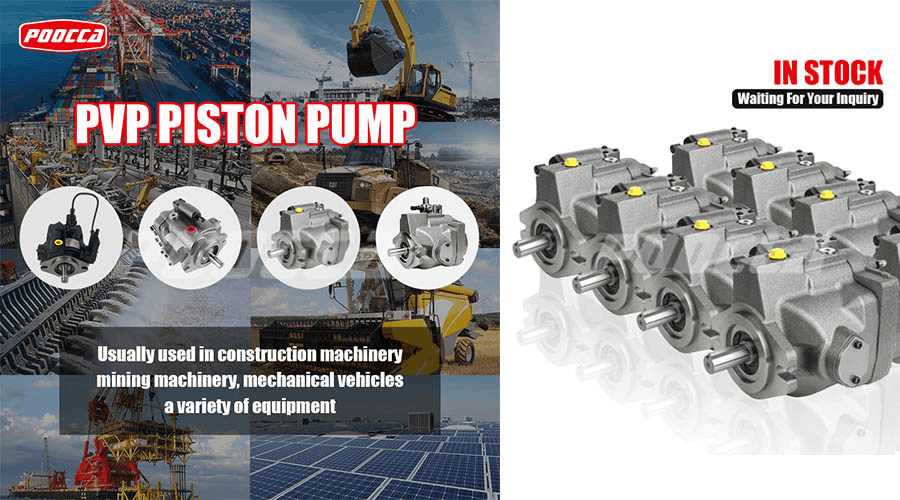

Applications of Piston Pumps

Piston pumps are found in many kinds of hydraulic systems. The pressure they make can run big machines and heavy tools. Besides that, they’re handy for smaller tasks too, like in cars, paint sprayers, or pressure washers.

POOCCA provides a wide selection of top-notch piston pumps perfect for uses in industries like construction machinery, injection molding machines, metallurgy, petroleum processing equipment, and more.

Control Valves

Flow Control Valves

Flow Control Valves: This valve adjusts how fast fluid moves by changing the size of the openings inside it where fluid passes through.

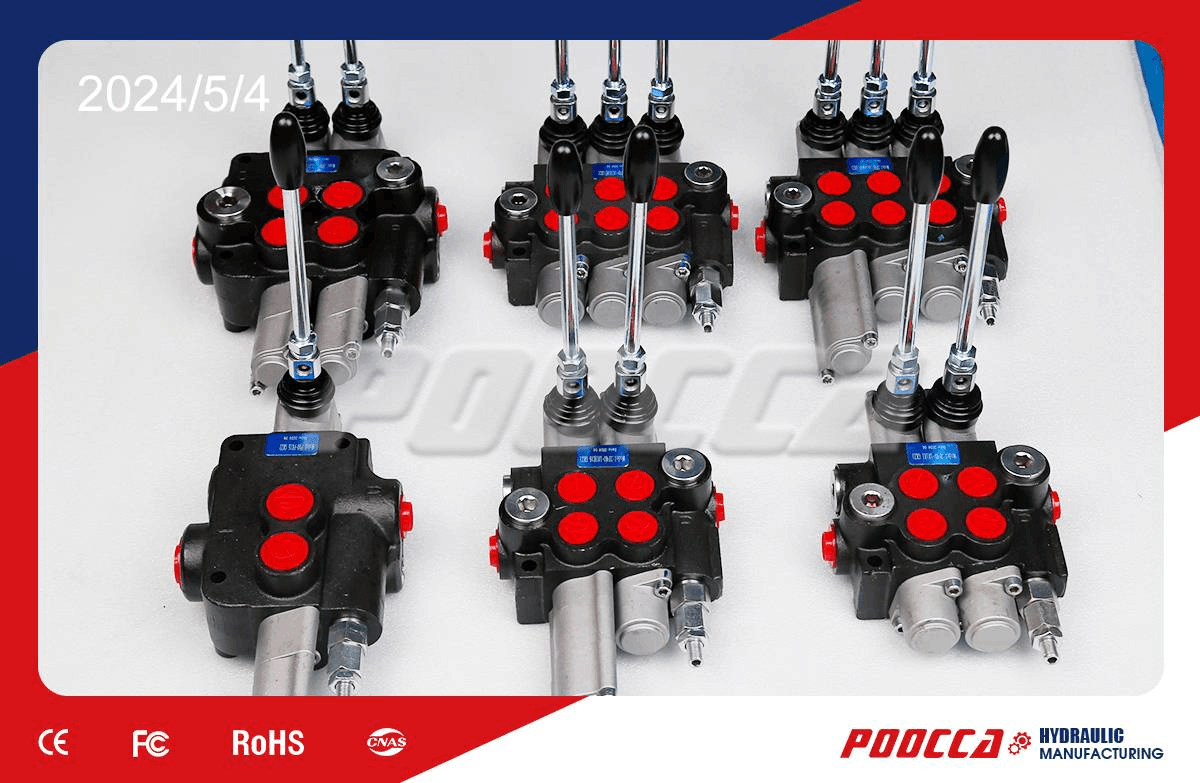

Direction Control Valves

Direction Control Valves: This valve makes sure fluid goes the right way. Some types, like check valves, keep fluid flowing in one direction and stop it from going backward.

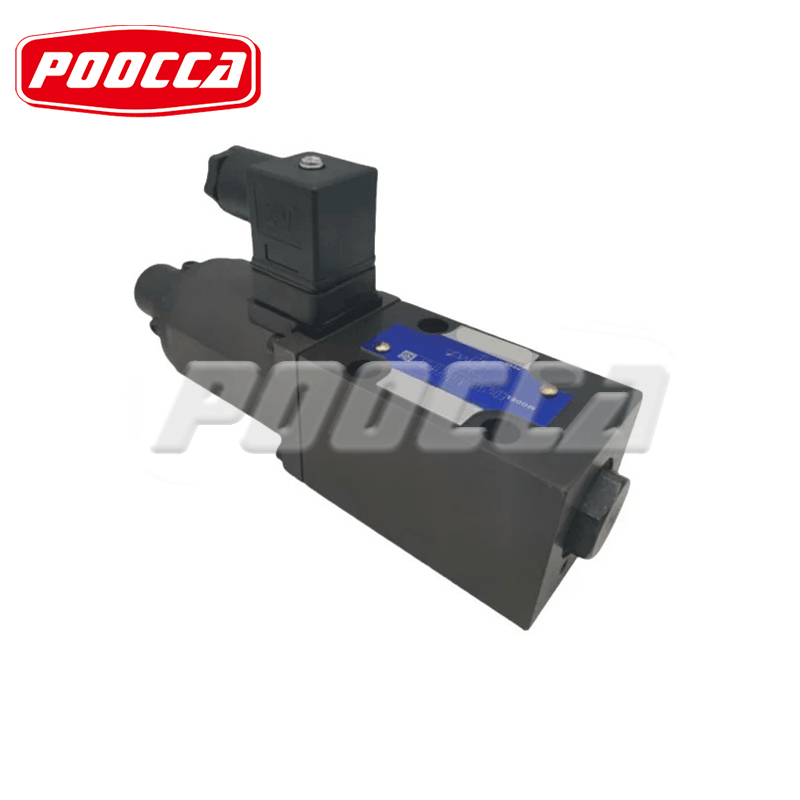

Pressure Control Valves

Pressure Control Valves: This valve manages and switches pressure levels by tweaking its settings as needed.

Configurations and Control Methods

Each type comes in different setups, from inline to flanged or sub-plate mounting, depending on what the system needs. Where they’re placed affects how they work in hydraulic circuits.

Control valves can be run by hand or with electronics, based on how complex the system is. Their position might be controlled using actuators or extra tools like temperature gauges or flow meters.

POOCCA’s directional hydraulic control valves, such as the P40/P80/P120 series, have a small build with adjustable relief valves. They’re great for tractors, cranes, lawn mowers, and other equipment.

Applications of Control Valves

Control valves are used in lots of hydraulic systems along with different pumps, including piston pumps. You’ll see them in braking systems, printing presses, construction tools, and more.

Similarities Between Piston Pumps and Control Valves

Both piston pumps and control valves help manage flow and pressure in hydraulic systems. They’re often used together in machines that rely on hydraulics, especially in setups with many control parts and piston-driven power sources.

Differences Between Piston Pumps and Control Valves

One big difference is how they work. Piston pumps are usually powered by spinning driveshafts linked straight to them, so you can change things by adjusting speed. On the other hand, control valves rely on hand-operated levers or automatic electronic systems to manage things.

Another point to remember is that control valves are needed in all kinds of hydraulic systems, no matter if they use gear, vane, rotary, or piston pumps. They play a common role everywhere. But piston pumps are only used in specific cases where high pressure is needed from positive displacement setups. That’s why they’re not always required in every system and differ in their basic purpose and function.

FAQ

How long has your company been established?

POOCCA hydraulic manufacturer was established in 2006 and has 26 years of experience in the hydraulic industry.

What products does POOCCA specialize in?

We have up to 1,600 product categories, mainly engaged in gear pumps, piston pumps, vane pumps, motors, hydraulic accessories, hydraulic valves, etc.

What warranty do your products carry?

12 months

Where are your production facilities located?

Our factories are located in Guangdong, Jiangsu, and Zhejiang. The annual export volume is as high as 16 million US dollars.

Do you offer international shipping?

Yes, we offer expedited international shipping options for your convenience. Please contact our sales team to discuss your specific requirements.

How do I choose suitable hydraulic components like piston pumps?

Think about things like flow rate needs (L/min), working pressure (bar/psi), the setting where it’ll be used (temperature range), and if it fits with your current system or parts. Also, talk to our technical team. They’ll help suggest the best options to match your needs, making sure you get good performance, reliability, and value over time.