Menu

Close

Menu

Close

We at POOCCA Hydraulic Suppliers also offer a wide range of flange mounted and surface mounted hydraulic motors. Currently, our hydraulic motors range in displacement from 0.47 cubic inches to 0.93 cubic inches. Additionally, we offer a wide selection of motors with varying torque and power ratings (4.5 to 12 horsepower).

There are many types for you to choose from. POOCCA is a one-stop hydraulic purchasing mall. You are welcome to send your requirements. We will provide you with affordable quotations, detailed product parameters, dimensions, physical pictures and other specific information.

Rexroth motor:A2FM A6VM A6VE…

Parker motor:TF TJ TB…

Earon motor:2000 4000 6000 series…

Danfoss motor:OMP OMR OMH…

Gear motor:AZMF ALM GHM…

(only display part)

Our manufacturing facility houses many CNC machines capable of producing high-quality hydraulic components and replacement parts.

POOCCA Hydraulic (Shenzhen) Co., Ltd. was established in 1997 and has four companies in Hong Kong, Guangdong, Jiangsu and Zhejiang. We are a comprehensive hydraulic service company specializing in the research and development, manufacturing, maintenance and sales of hydraulic pumps, motors, valves and related parts. With extensive experience in providing power transmission and drive solutions to hydraulic system users around the world, we have a strong reputation in the industry.

Over the past two decades, POOCCAHydraulics has continued to grow and innovate in the field of hydraulics. We have won the trust of domestic and foreign manufacturers and established strong corporate partnerships. Our annual export volume is up to US$16 million and exported to more than 100 countries. We have established long-term and stable cooperative relationships with dealers in more than 75 countries, including the United States, Indonesia, Mexico, Thailand, Russia and Brazil.

POOCCA hydraulic adopts design concept. We can customize hydraulic motors for sale according to your requirements. Hydraulic products are diverse. POOCCA Hydraulic Factory sells gear pumps, piston pumps, vane pumps, hydraulic valves, hydraulic cylinders, hydraulic accessories, and motor products at factory prices.

What is a hydraulic motor and what role does it play in its application? POOCCA has many years of hydraulic experience in the hydraulic industry.

A hydraulic motor is an energy conversion device that converts hydraulic energy into mechanical energy. It drives the movement of mechanical equipment through the pressure and flow of liquid. Hydraulic motors have the characteristics of simple structure, small size, light weight, large output torque, and smooth start. Therefore, they have been widely used in various occasions that require large torque output.

The working principle of hydraulic motors is to use the pressure and flow of liquid to drive the rotor to rotate. When liquid flows from a high-pressure area to a low-pressure area, a pressure difference is created on the vanes or pistons, which causes the rotor to rotate. The output torque of the hydraulic motor is proportional to the input flow and the pressure of the hydraulic oil. Therefore, by adjusting the flow and pressure of the hydraulic pump, the output torque of the hydraulic motor can be controlled.

Hydraulic motors can be used in industry, agriculture, transportation, aviation and other scenarios. Hydraulic motors play an important role in various industrial production lines.

In the complex hydraulic world, POOCCA believes that the role of hydraulic motors is still very important, providing power for countless machinery and systems in various industries. At its core, a hydraulic motor is a mechanical device that converts hydraulic energy (usually provided by hydraulic oil under pressure) into rotary mechanical motion. Unlike hydraulic pumps, which facilitate fluid movement, hydraulic motors use the energy of the flowing fluid to create rotational motion.

Hydraulic motors work on the basic principles of fluid pressure and flow. When hydraulic fluid is directed into a motor, it encounters a series of chambers or gears, initiating a process that results in the creation of rotational force. There are many types of hydraulic motors, each with its own unique design and operating characteristics, including gear motors, vane motors, and piston motors.

Types of hydraulic motors:

Gear motor:

Gear motors feature interlocking gears that produce rotational motion.

These motors are compact, cost-effective and suitable for applications with moderate pressure and speed requirements.

Commonly used in conveyor systems, industrial machinery and automotive applications.

Vane motor:

Vane motors utilize blades mounted on a rotor to produce rotational motion.

Vane motors are known for their efficiency, providing smooth, consistent operation.

Applications include material handling equipment, machine tools and marine systems.

Piston motor:

Piston motors use pistons within cylinders to convert hydraulic energy into mechanical motion.

These motors feature high torque and power and are suitable for heavy-duty applications.

Commonly found in construction equipment, agricultural machinery and other demanding industrial environments.

POOCCA According to their different structures and working principles, hydraulic motors can be mainly divided into three types: gear type, plunger type and vane type. Gear hydraulic motor is a common type of hydraulic motor. Its main features are simple structure, reliable operation and high efficiency. The gear hydraulic motor uses the pressure of hydraulic oil to act on the gear, causing the gear to rotate, thereby driving the mechanical equipment to operate. Due to its high efficiency and stable performance, gear hydraulic motors are widely used in various industrial equipment, such as excavators, cranes, forklifts, etc.

A plunger hydraulic motor is a hydraulic motor that uses a plunger to reciprocate in a cylinder to produce mechanical motion. The plunger hydraulic motor is characterized by large torque and smooth start, but its efficiency is relatively low. Plunger hydraulic motors are usually used in equipment requiring large torque output, such as large excavators, mining loaders, etc.

The vane hydraulic motor is a hydraulic motor that uses liquid pressure to act on the blades to cause the blades to rotate. Vane hydraulic motors are characterized by small size and light weight, but low torque. Therefore, vane hydraulic motors are usually used in equipment requiring small torque output, such as small forklifts, lifting platforms, etc.

Finally, gear type, piston type and vane type are the three main types of hydraulic motors, each with unique advantages and application areas. With the continuous development of hydraulic technology, we look forward to seeing more efficient and high-performance hydraulic motors appear on the market to provide more powerful power for mechanical equipment in various industries.

Among the many styles of POOCCA motors, they can be classified as hydraulic piston motors: Rexroth A10FM, A4FM, A2FM, A2FE, S6VM, S6VE,. Parker F11, F12. Poclasin MK, MKE, MS, MSE. Hagglunds CA, CB… …The above product models can be called plunger motors.

Hydraulic piston motor is a type of hydraulic motor that converts hydraulic energy into mechanical energy through the movement of the piston in the cylinder. Among the various designs of hydraulic motors, axial piston motors are particularly notable for their efficiency, versatility, and ability to deliver high torque and power.

Axial piston configuration:

The main design feature of hydraulic piston motors is that the axial pistons are arranged in a circle or semicircle.

When hydraulic oil is directed into the motor, these pistons move in and out of the cylinder, creating a rotational motion.

Swash plate mechanism:

The axial piston is usually connected to a swash plate, which is tilted at an angle to control the displacement of the piston.

When the swash plate tilts, it changes the effective stroke of the piston, regulates the flow of hydraulic oil and determines the speed and torque of the motor.

Variable displacement:

Many hydraulic piston motors feature variable displacement, allowing precise control of speed and torque output.

This variability is achieved by adjusting the angle of the swash plate or employing advanced electro-hydraulic controls.

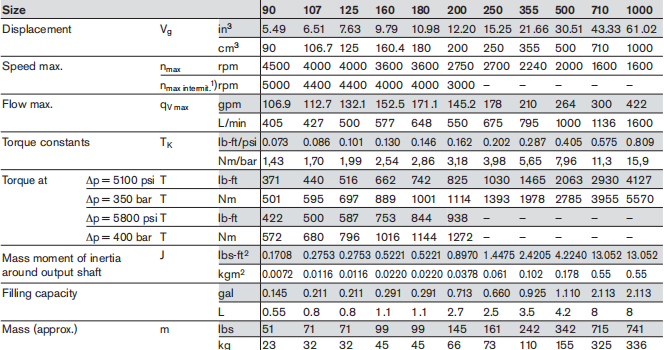

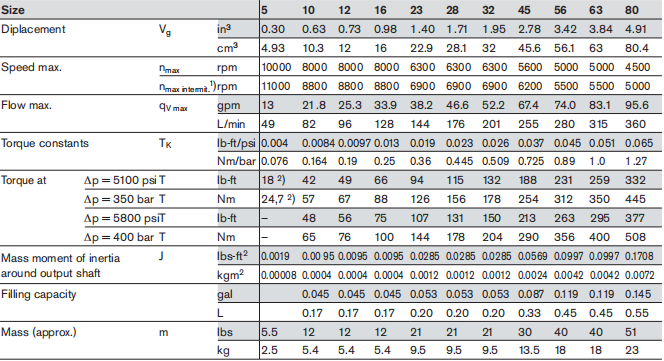

A2FM motor size:5,10,12,16,23,28,32,45,56,63,80,90,,107,125,160,180,200,250,355,500,710,1000.

Nominal pressure 315 bar, maximum pressure 350bar, specifications between 10-200, nominal pressure 400bar, maximum pressure 450bar, specifications 250 to 1000, nominal pressure 350bar, maximum pressure 400bar.

The fixed displacement motor A2FM is not suitable for use with HFA hydraulic oil. When using HFB, HFC, HFD or environmentally friendly hydraulic oils, the correct selection of hydraulic oil requires knowing the operating temperature in relation to the ambient temperature: oil line temperature in a closed circuit, tank temperature in an open circuit. When selecting a hydraulic oil, the operating viscosity within the operating temperature range should be within the optimal range. The case drain temperature (affected by pressure and speed) may be higher than the oil line temperature or tank temperature. However, the temperature of any part of the component may not exceed 115 °C. The temperature differences specified below should be taken into account when determining the viscosity of the hydraulic oil at the bearing. If the above conditions cannot be maintained due to extreme operating parameters, we recommend flushing the housing at port U (sizes 250 to 1000) or using flushing and charging valves.

The allowed pressure load of this POOCCA motor

The service life of the shaft seal is affected by the rotational speed of the axial piston unit and the case drain pressure (case pressure). The average pressure difference between case and ambient pressure is 2 bar, which is not continuously exceeded at normal operating temperatures. For higher pressure differentials at lower rpm. The maximum permissible value for instantaneous pressure peaks (t < 0.1 s) is 10 bar. The service life of the shaft seal decreases as the frequency of pressure peaks increases. Case pressure must be equal to or greater than ambient pressure

Advantages of hydraulic piston motors:

high efficiency:

Hydraulic piston motors are known for their high mechanical efficiency, making them suitable for applications requiring optimal energy utilization.

Axial design minimizes friction losses, helping to improve overall efficiency.

Compact and powerful:

Axial piston motors offer a high power-to-weight ratio, making them ideal for applications where space and weight considerations are critical.

Its compact design allows integration into tight spaces without compromising performance.

Transmission and Torque:

The ability to vary displacement allows hydraulic piston motors to deliver a wide range of speeds and torques, providing flexibility in different applications.

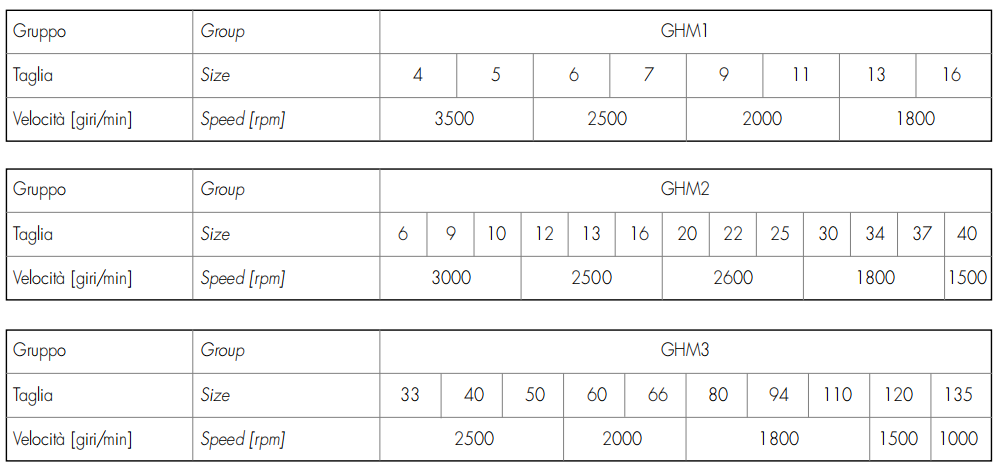

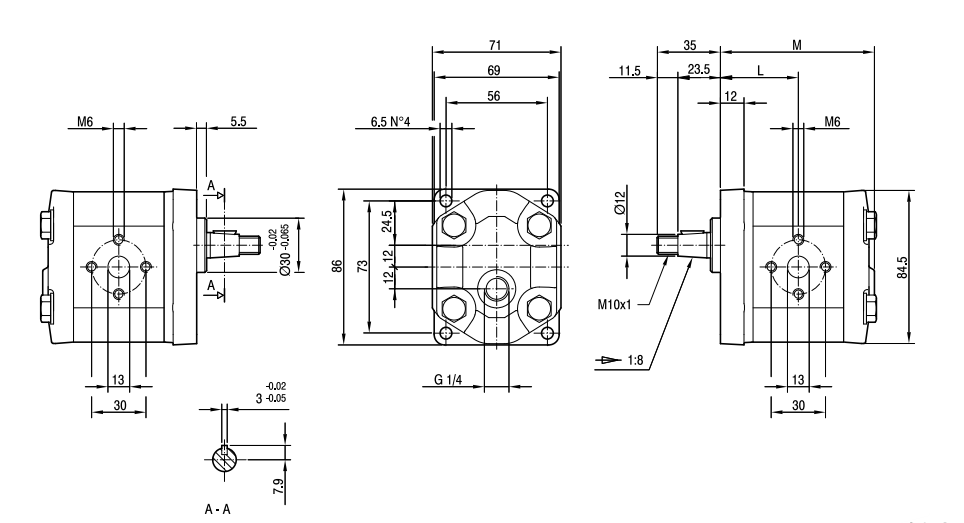

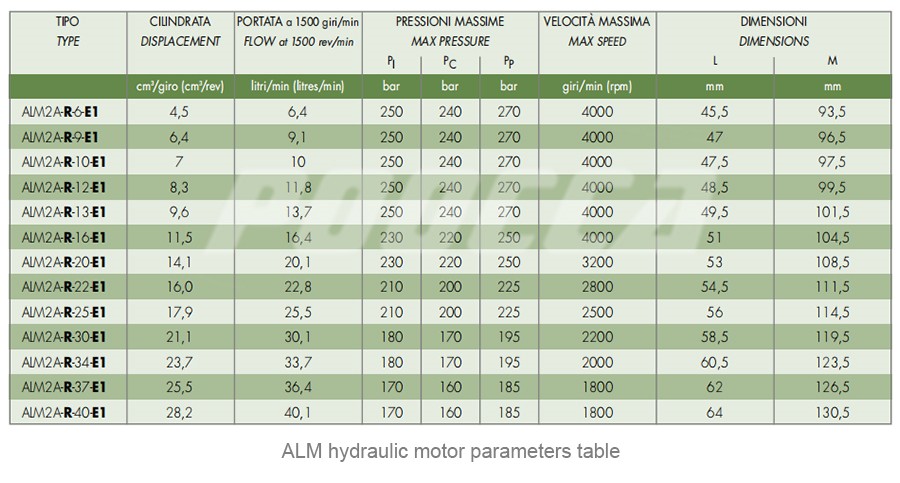

POOCCA Marzocchi GHM gear motors are available in 1 group, 2 groups, and 3 groups.

GHM1 size: 4,5,6,7,9,11,13,16. Speed 3500-1800rpm.

GHM2 size: 6,9,10,12,13,16,20,22,25,30,34,37,40. Speed 3000-1500rpm.

GHM3 size: 33, 40, 50, 60, 66, 80, 94, 110, 120, 135. Speed 2500-1000rpm.

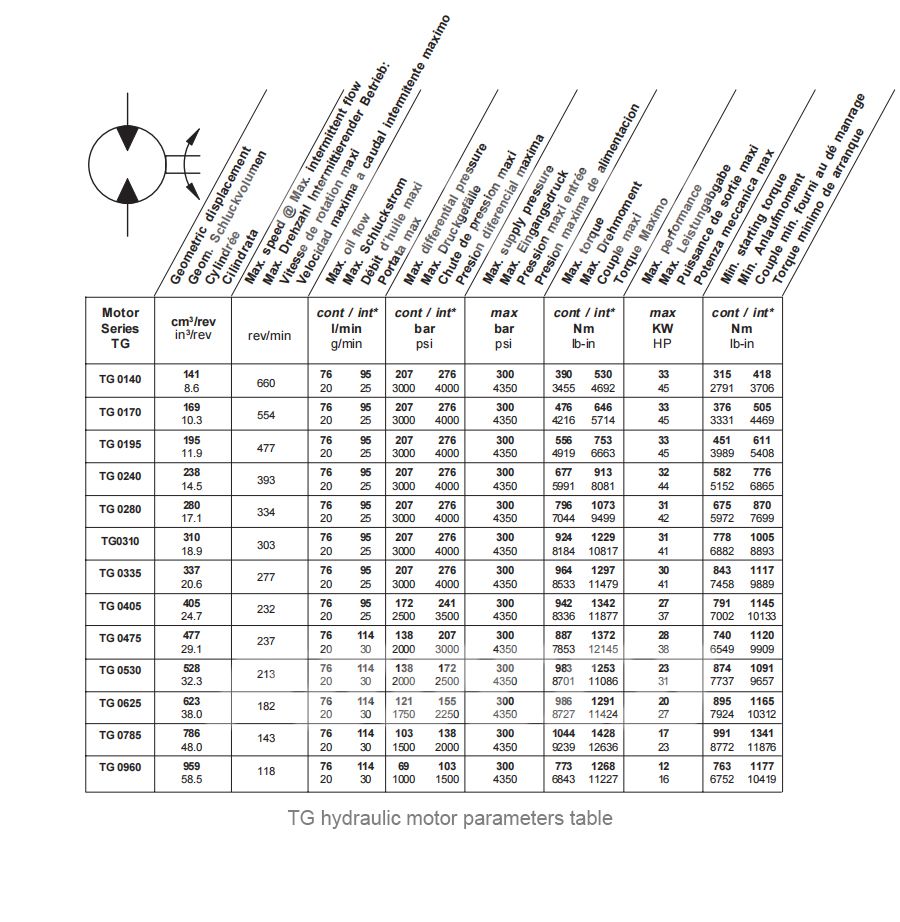

POOCCA also has a variety of gear motors: Danfoss SNM, SKU, SNU.Rexroth AZMF, AZMG.Casappa PLM…

Send your request to POOCCA to get more product-related parameters, pictures, drawing dimensions, etc.

A hydraulic gear motor is a device that converts hydraulic energy into mechanical energy. It uses the pressure of hydraulic oil to drive gear rotation to achieve power output. Hydraulic gear motors have the advantages of simple structure, small size, light weight, and reliable operation.

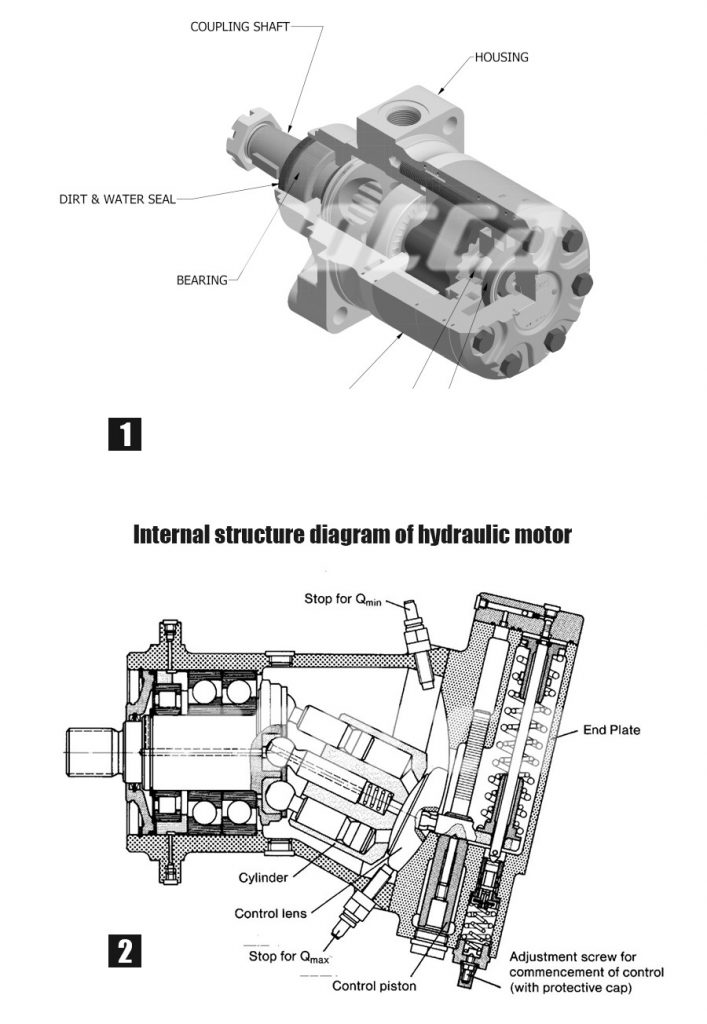

The working principle of a hydraulic gear motor is to use a hydraulic pump to convert mechanical energy into hydraulic energy, and then control the direction and pressure of the hydraulic oil through a hydraulic valve, so that the hydraulic oil drives the gear to rotate, thereby achieving power output. The main components of a hydraulic gear motor include: gears, housings, shafts, bearings, seals, etc.

Gears: The gears of hydraulic gear motors are usually made of high-strength materials to ensure sufficient strength and wear resistance. The tooth profile design of the gear is of great significance for improving the working efficiency and transmission ratio of the hydraulic gear motor.

Housing: The housing of a hydraulic gear motor protects internal components and transmits torque. The casing is usually made of aluminum alloy or cast iron to meet the needs of different working conditions.

Shaft: The shaft of a hydraulic gear motor supports the gear and transmits torque. The surface of the shaft is usually specially treated to improve its wear resistance and fatigue resistance.

Bearings: The bearings of hydraulic gear motors mainly bear the radial and axial loads between the gear and the housing. The selection and installation of bearings are crucial to ensure the normal operation and extended service life of hydraulic gear motors.

Seals: Hydraulic gear motor seals are mainly used to prevent hydraulic oil leakage and external contaminants from entering. Commonly used seals include rubber sealing rings, polytetrafluoroethylene sealing rings, etc.

POOCCA hydraulic vane motors include Parker M5ASF, M5AS, Denison M3, M4C, M4D, M4E

These hydraulic vane motors are a type of hydraulic motor that convert hydraulic energy into mechanical motion using a series of vanes mounted on a rotor inside a cylindrical chamber.

Hydraulic vane motors consist of a rotor with slots for the vanes to slide in and out. These blades are typically made from materials such as carbon or synthetic polymers.

When hydraulic oil is directed into the motor, it causes the blades to extend and retract, creating chambers that allow fluid to enter and exit, creating a rotational motion.

Centrifugal force and output torque:

The rotation of the rotor creates centrifugal force, which presses the blades against the housing.

This interaction creates a seal between the vanes and chamber walls, contributing to efficient fluid displacement and enabling the motor to deliver significant output torque.

Compact design and efficiency:

Hydraulic vane motors are known for their compact design, making them suitable for applications where space is limited.

The design also increases efficiency, providing a reliable and cost-effective solution for a variety of hydraulic power needs.

Advantages of hydraulic vane motors:

Running smoothly:

Hydraulic vane motors provide smooth and consistent operation, making them suitable for applications requiring precise control.

The sliding motion of the blades reduces noise levels compared to some other types of hydraulic motors.

High starting torque:

Vane motors have high starting torque, which makes them particularly effective in situations where overcoming initial resistance is critical.

This property is very advantageous in applications such as conveying systems and hydraulic presses.

Versatility and adaptability:

Hydraulic vane motors are widely used and adaptable to various working conditions.

Their ability to operate at different pressures and speeds makes them suitable for a wide range of industrial applications.

The speed limit of a hydraulic motor is affected by many factors, including the flow rate and pressure of the hydraulic pump, the viscosity of the hydraulic oil, and the design parameters of the motor. Hydraulic motors can range in speed from a very low few revolutions per minute (RPM) to thousands of revolutions. The specific speed limit depends on the type and size of the hydraulic motor selected.

In order to realize the full potential of a hydraulic motor, its rotational speed needs to be precisely controlled. Currently commonly used hydraulic motor speed control methods include the following:

Variable pump control: By adjusting the output flow and pressure of the hydraulic pump, precise control of the hydraulic motor speed can be achieved. This method is suitable for applications that require frequent rotational speed adjustments.

Frequency conversion speed control: By changing the power supply frequency of the motor, the output flow and pressure of the hydraulic pump can be adjusted, thereby controlling the speed of the hydraulic motor. This method has high speed regulation accuracy and response speed.

Valve-controlled speed control: By adjusting the opening and closing time of the hydraulic valve, the speed of the hydraulic motor can be controlled. This method is suitable for applications that do not require high speed regulation.

Although hydraulic motors have a large speed range and flexible speed regulation capabilities, they still face some challenges in practical applications. Here are some common challenges and corresponding solutions:

Insufficient starting torque: The hydraulic motor may face insufficient torque when starting, resulting in the inability to start the load normally. To solve this problem, methods such as increasing the displacement of the hydraulic pump or using a two-stage pump can be used to increase the starting torque.

Poor low-speed stability: When operating at low speed, the stability of the hydraulic motor may be affected, resulting in large speed fluctuations. To solve this problem, methods such as increasing the damping of the hydraulic system or using a low-pulsation hydraulic pump can be used to improve low-speed stability.

High-temperature operation problems: Hydraulic motors may face high-temperature operation problems when running at high speeds, leading to problems such as hydraulic oil deterioration and leakage. To solve this problem, methods such as adding a cooler or using high-temperature resistant hydraulic oil can be used to reduce the temperature.

Noise and vibration: Hydraulic motors may produce noise and vibration during operation, affecting the working environment and the life of the equipment. To solve this problem, noise and vibration reduction measures can be adopted, such as using low-noise hydraulic pumps and adding anti-vibration pads.

POOCCA sells hydraulic vane motors. Taking into account the working environment, the manufacturer can use the vane motor at the lowest temperature, especially for the market in severe cold areas. This specially customized product is also beneficial to the operation and use time of your machinery.

In complex hydraulic systems, torque is a key parameter that determines the rotational force exerted by the hydraulic motor. Understanding the torque of hydraulic motors is very interesting and referenced for engineers, technicians and enthusiasts in the hydraulic industry or POOCCA hydraulics.

Torque is a fundamental physical quantity that represents the tendency of a force to cause an object to rotate about an axis. In a hydraulic motor, torque is the force that drives the rotational motion of the motor’s output shaft. It is usually measured in units such as Newton meters (Nm) or pound feet (lb-ft).

A hydraulic motor is a device that converts hydraulic pressure into mechanical energy and produces rotational motion. Torque is a key performance parameter of a hydraulic motor because it determines the motor’s ability to provide the rotational force required to drive a load.

The basic principle:

When hydraulic oil is directed into a hydraulic motor, it exerts pressure on the motor’s internal components, creating torque on the output shaft.

The torque generated by the motor is transmitted to the connected machinery or system, allowing it to perform various tasks such as lifting, rotating or moving.

The relationship between torque and speed:

The torque and speed of a hydraulic motor are inversely proportional to each other, which is called the torque-speed curve.

As torque increases, speed decreases and vice versa. This relationship is critical to understanding the motor’s performance characteristics under different operating conditions.

Factors affecting hydraulic motor torque:

Pressure and flow:

The torque produced by a hydraulic motor is directly proportional to the pressure of the hydraulic oil.

Higher pressure results in increased torque, which emphasizes the importance of maintaining appropriate pressure levels for optimal motor performance.

Motor design:

The design of a hydraulic motor, including the type of motor (gears, vanes, piston), affects torque capability.

For example, piston motors typically offer higher torque than gear or vane motors, making them suitable for applications requiring large amounts of rotational force.

Displacement and size:

The displacement of a hydraulic motor refers to the volume of liquid displaced per revolution and is a key factor affecting torque.

Larger displacement motors typically produce higher torque, but the physical size and weight of the motor also increase accordingly.

efficiency:

The efficiency of a hydraulic motor affects the actual torque delivered to the output shaft.

High-efficiency motors convert a higher proportion of hydraulic power into mechanical power, maximizing the torque available to perform useful work.

Heat generation:

High torque operation results in increased heat generated by the hydraulic motor.

Proper cooling mechanisms and temperature monitoring are important to prevent overheating and maintain optimal performance.

POOCCA After you purchase any of our products, we will provide you with 24-hour online technical support attentively.

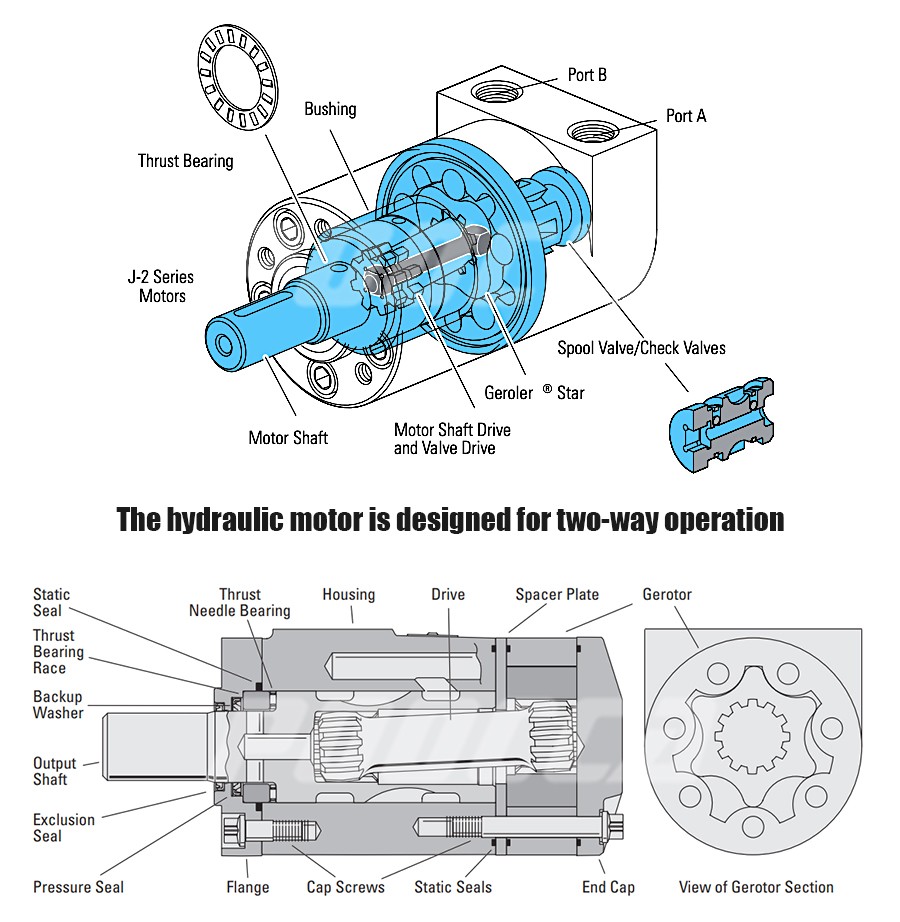

The ability of a hydraulic motor to rotate in both directions is a major factor that directly affects its versatility and application.

Learn the basics of hydraulic motors:

Before exploring bidirectional functionality, it is important to understand the basic principles of hydraulic motors. A hydraulic motor is a device that converts hydraulic energy into mechanical energy to produce rotational motion. They are widely used in various industries to power machinery and systems efficiently and accurately.

Bidirectional operation:

Double-sided design:

Many hydraulic motors are inherently designed to operate bidirectionally, meaning they can turn in both clockwise and counterclockwise directions.

The reversible design is achieved through a symmetrical configuration of internal components, allowing the motor to seamlessly adapt to changes in fluid flow and pressure.

Variable displacement engine:

Hydraulic motors with variable displacement capability inherently support bidirectional operation. These motors regulate the displacement of hydraulic oil to control speed and direction.

Variable displacement motors are versatile and can be used in situations where bi-directional motion is critical.

Valve configuration:

Hydraulic systems use valves to control the direction of fluid flow. The configuration and type of valve used in a hydraulic motor system affects its ability to turn in both directions.

Proportional and directional control valves with bi-directional functionality facilitate seamless operation.

System design and fluid flow:

The overall design of a hydraulic system, including the arrangement of components and the efficiency of fluid flow, affects bidirectional capabilities.

Proper system design ensures that the hydraulic motor can transition smoothly between directions and respond quickly to changes in fluid pressure.

Heat generation:

Bidirectional operation results in increased heat generation in the hydraulic system.

Wear:

Bidirectional motion, especially under heavy loads, can cause wear on the internal components of the hydraulic motor. POOCCA reminds you that after your power source is put on the machine, please perform regular maintenance and monitoring, and do a series of things to solve the problem and extend the use time of the hydraulic motor.

A hydraulic motor is a device that converts hydraulic energy into mechanical energy. Compared with traditional electric motors, hydraulic motors have the following significant advantages:

High power output capability: Hydraulic motors can provide large power output and are suitable for equipment requiring high torque and high speed. Its output power can reach thousands of kilowatts, meeting the needs of various heavy machinery and equipment.

Smooth operation: Hydraulic motors can achieve smooth operation and reduce mechanical vibration and noise. This is very important for some applications that have high requirements on the working environment, such as hospitals, laboratories, etc.

Large starting torque: The hydraulic motor has large starting torque and can easily start heavy-load equipment. Compared with electric motors, hydraulic motors do not require additional power support when starting, reducing energy consumption.

Convenient speed regulation: The hydraulic motor can achieve precise speed regulation by adjusting the flow and pressure of the hydraulic pump. This allows the hydraulic motor to respond flexibly to different working conditions and improve work efficiency.

High reliability: Hydraulic motors have high reliability and durability. Since the fluid in the hydraulic system is incompressible, the hydraulic motor will not get stuck or lose control due to load changes. In addition, the hydraulic motor has a simple design and low maintenance costs.

Strong adaptability: Hydraulic motors can work normally in harsh working environments, such as high temperature, low temperature, high pressure, etc. This gives hydraulic motors unique advantages in some special industries, such as petroleum, chemical industry, aerospace, etc.

In addition to making regular products, POOCCA also accepts customization. Whether it is the pressure of the product, the size, or the nameplate or packaging LOGO, we can customize it and serve you throughout the process.

POOCCA hydraulic manufacturer was established in 1997 and has 26 years of experience in the hydraulic industry.

We have up to 1,600 product categories, mainly engaged in gear pumps, piston pumps, vane pumps, motors, hydraulic accessories, hydraulic valves, etc.

Our product order delivery times may vary based on the specific product and its availability.

Regular products take 5-7 days, special products depend on customization time and quantity.

12 months

Our factories are located in Guangdong, Jiangsu and Zhejiang. The annual export volume is as high as 16 million US dollars.

We accept a variety of payment methods including credit card, bank transfer, PayPal, and more.

For large orders, 30% can be paid in advance and the remaining 70% is paid before shipment.

Yes, we offer expedited international shipping options for your convenience. Please contact our sales team to discuss your specific requirements.

Our products adhere to industry standards and often hold certifications such as [Certification Name]. We are committed to maintaining the highest quality and safety standards.

Yes, we offer product samples and demos to help you choose. Please contact our sales team to arrange.

Yes, we have extensive references and case studies to prove the successful implementation of the product. Please contact our sales team for these resources.

If there is a problem with the quality of the product, it can be returned or exchanged if it complies with the return and exchange policy.

Our products undergo strict quality control and testing procedures. We also have a dedicated quality assurance team to maintain the highest standards. In addition, we regularly invest in research and development to improve our products and stay at the forefront of the industry.

Yes, we offer volume discounts and can provide customized solutions for bulk orders. Please contact our sales team to discuss your specific requirements and pricing options.

You can track your order using the tracking number provided after your order is shipped. Our shipping partners offer tracking services so you can track the progress of your shipment online.

Yes, we provide online installation instructions, maintenance instructions, and technical support resources for our products. Our customer service and technical teams are here to help.

We prioritize sustainability and environmentally responsible manufacturing. Our products are designed with the environment in mind, and we actively participate in sustainability initiatives.

We welcome tours of our facilities and headquarters. Please contact us to arrange a visit and we will be happy to provide insight into our operations and quality control measures.

Consider factors such as flow, pressure and system requirements. Of course, we will also assist you in selection and find the product that suits you.

Hydraulic hoses and fittings are used to carry hydraulic fluid between components in a hydraulic system.

Hydraulic oil transmits power, lubricates components and dissipates heat within the system.

Change and filter hydraulic oil regularly, keep the system clean, and use high-quality filters.

Filtration removes contaminants to maintain system performance and extend component life.

Regular maintenance ensures system reliability, efficiency and minimizes downtime.

Check for leaks, monitor pressure and temperature, and inspect components for wear or damage.

The accumulator stores hydraulic energy, suppresses pressure fluctuations, and can provide emergency power.

Hydraulic valves control fluid flow, pressure, and direction to manage system functions.

Proportional valves provide precise control of flow or pressure, while directional valves manage fluid direction.

Consider factors such as flow, pressure and control requirements to make the best choice.

Hydraulic cylinders are linear actuators used in applications such as construction equipment and manufacturing.

The cylinder extends and retracts when hydraulic oil pressurizes or depressurizes the sides of the piston.

Options include JIC, NPT, SAE and metric fittings for connecting hoses and components.

Regular inspections, proper training and safety protocols are vital to maintaining safety.

Flushing before system assembly or during maintenance removes contaminants and prevents damage.

Proper lubrication, maintenance and compliance with recommended operating parameters are critical.

Seals prevent fluid leakage and maintain pressure within components.

Viscosity affects the fluid's ability to flow and lubricate; it is chosen based on system requirements.

Quick couplers provide a quick, secure connection between hydraulic lines and components.

Consider load, speed, and pressure requirements to select an appropriately sized hydraulic motor.

Hydraulic systems provide high power-to-weight ratio, precise control, and the ability to transmit power over long distances.

Pressure relief valves protect the system from overpressure by releasing excess fluid.

Regular maintenance, monitoring for signs of wear, and following manufacturer's operating and maintenance guidelines can extend the life of components and systems.

Factors to consider include material compatibility, temperature range and specific application requirements.

POOCCA Hydraulics is a powerful hydraulic enterprise integrating R&D, manufacturing, sales and maintenance. Its products are exported to more than 120 countries. Its quality, price and service are deeply recognized and trusted by customers.

Welcome to contact us via whatsapp

Welcome to contact us using WeChat