Vane pumps stay among the most popular positive displacement pumps in hydraulic and fluid-handling systems. They give smooth flow with very little pulsation. They also run quietly and show great volumetric efficiency. These pumps work really well in medium-pressure situations. Plus, they handle a wide range of viscosities. That makes them a top pick for fixed-demand setups as well as variable-demand ones in today’s industrial, mobile, and process machines.

Introduction to Vane Pumps

What is a Vane Pump?

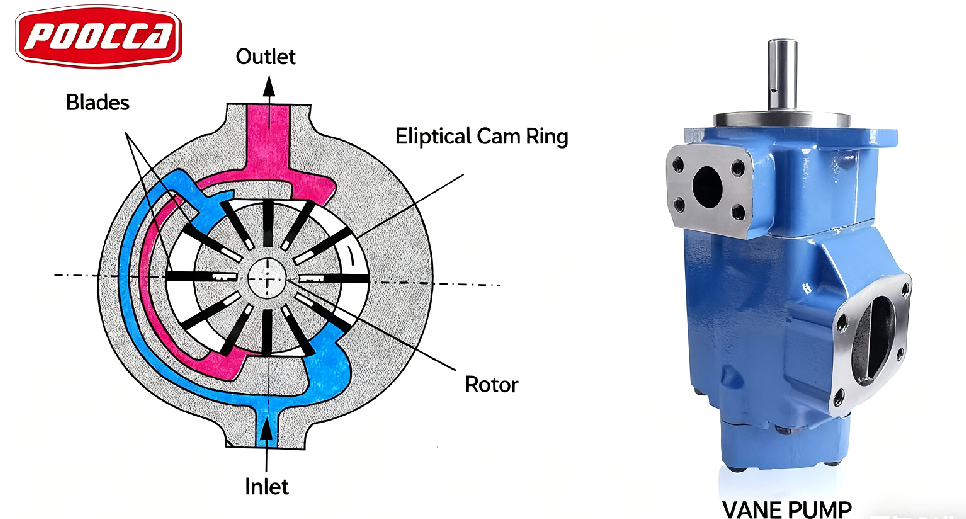

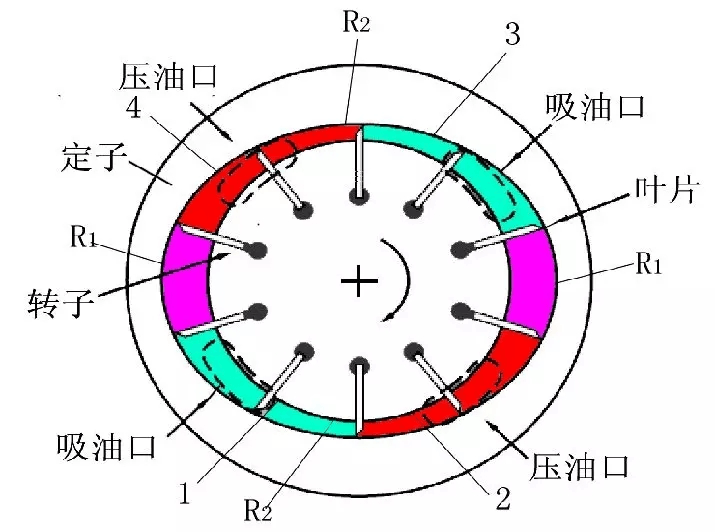

A vane pump is a rotary positive displacement pump. It uses sliding vanes that sit in radial slots on an off-center rotor. When the rotor spins inside the pump housing, centrifugal force (or springs in certain models) forces the vanes outward. This keeps them touching the cam ring or casing wall all the time. As a result, expanding chambers form on the suction side to pull fluid in. At the same time, contracting chambers appear on the discharge side to push fluid out. This setup provides steady flow and almost no pressure ripple.

Tight seals form between the vanes, rotor, and cam ring. Because of this, internal leakage stays very low. That helps create high volumetric efficiency, often above 90% even after long use. Vane pumps manage clean fluids well. These range from low-viscosity solvents and fuels to medium-viscosity hydraulic oils. Special materials also let them work with tougher fluids.

Common Applications Include:

- Hydraulic power units for machine tools, injection molding, and mobile equipment

- Automotive power steering and transmission systems

- Centralized lubrication systems in heavy industry

- Refrigerant circulation in commercial HVAC and chillers

- Fuel supply and transfer in diesel engines and aviation systems

- Precise metering and dosing in chemical and pharmaceutical processing

Types of Vane Pumps

Fixed-displacement vane pumps deliver constant output flow based on speed. They suit systems that need steady delivery. Variable-displacement vane pumps let you adjust flow during operation. They do this via cam-ring shifts or pressure compensator setups. This brings big energy savings in load-sensing and demand-based circuits.

| Type | Flow Characteristic | Typical Applications | Primary Advantages |

|---|---|---|---|

| Fixed-Displacement | Constant flow at given speed | Lubrication systems, constant-pressure hydraulics | Simple construction, high reliability |

| Variable-Displacement | Adjustable flow (pressure or flow compensated) | Power steering, load-sensing hydraulics | Energy-efficient, responsive to demand |

Advanced Configurations and Design Variants

Many modern vane pump series now feature balanced designs. These use double or triple lobe cam rings. Such setups cut radial loads on the shaft and bearings. In turn, they extend service life during high-pressure or nonstop work. Intra-vane and pin-type vane setups also boost response speed. They lower wear when pressure changes quickly.

Key Applications of Vane Pumps

Industrial Hydraulic Power Units

Vane pumps supply precise, ripple-free flow to actuators in presses, shears, and material handling gear. They keep steady performance through different duty cycles.

Mobile Equipment Hydraulics

In construction, agricultural, and material-handling vehicles, vane pumps offer reliable power steering and extra functions. They handle shock loads and some contamination fairly well.

Lubrication and Circulation Systems

They provide continuous, non-pulsating flow. This ensures even oil spread to bearings, gears, and chains in compressors, turbines, and big machines. As a result, parts wear much less.

HVAC and Refrigeration Circuits

Low noise levels and stable pressure make vane pumps a good fit. They pump refrigerant in chillers, heat pumps, and commercial air-conditioning units.

Fuel and Chemical Transfer

Strong suction ability and material compatibility allow safe transfer. This covers diesel, jet fuel, solvents, and low-viscosity process fluids with little shear harm.

Working Principle of Rotary Vane Pumps

How Rotary Vane Pumps Operate

The pump works thanks to the off-center position between rotor and cam ring. This creates repeating volume changes.

Operation Sequence:

- Vanes stretch out completely at the widest spot along the eccentric path.

- The chamber on the suction side grows fast. This forms a vacuum and pulls fluid in through the inlet port.

- Fluid fills the space between vanes while rotation goes on.

- The chamber shrinks as it nears the narrowest eccentric point.

- Fluid gets squeezed and forced out through the discharge port under pressure.

The Role of Seals in Vane Pumps

Good sealing keeps efficiency high and stops cross-contamination. Main seal types include:

- Lip Seals — Shaft entry, low-to-medium pressure — Nitrile, Viton, PTFE — Cost-effective, good dirt exclusion

- Mechanical Face Seals — High-pressure shaft sealing — Carbon vs. silicon carbide, TC vs. TC — Extremely low leakage, long life

- O-Rings — Static ports, cartridge interfaces — FKM, EPDM, HNBR — Simple, wide chemical compatibility

- Gaskets — Cover plates, flange joints — Compressed non-asbestos, PTFE — High temperature and chemical resistance

- Bellows / Diaphragm — Special low-leakage or flexible needs — Elastomer composites — Vibration damping, thermal compensation

Components of a Vane Pump

The Rotor and Shaft Assembly

The rotor uses hardened alloy steel or strong composites. Many have diamond-like carbon (DLC) or nitride coatings. These give better resistance to wear and scoring.

Vanes: Materials and Design Variations

- Carbon-graphite vanes: Self-lubricating, excellent dry-run tolerance

- Hardened steel vanes: High strength for elevated pressures

- Composite / polymer vanes: Optimized for aggressive chemicals or low-viscosity fluids

Designs vary from basic fixed-length styles to intra-vane (pressure-balanced) types and spring- or pin-assisted sliding ones.

Cam Ring and Pump Housing

The cam ring sets the pumping shape. It is usually hardened and ground precisely. The housing—made from cast iron, ductile iron, or stainless steel—offers solid structure. It holds fluid and keeps all rotating parts lined up.

Performance Enhancements in Contemporary Designs

Many vane pumps today include anti-rattle parts, fast-response compensators, and through-drive options for tandem setups. These features make them fit better in complex multi-function hydraulic systems.

Maintenance Tips for Vane Pumps

Cleaning and Rebuild Procedures

Depressurize and isolate the unit first. Then disassemble it with care. Clean components using ultrasonic methods or solvent washing. Check vane tips and cam ring for scoring. Replace any worn items. Finally, reassemble everything with a thin layer of suitable fluid.

Lubrication and Fluid Management Best Practices

Always use fluids that match the manufacturer’s specs for viscosity, cleanliness, and additives. Add offline filtration and do regular oil checks. Never mix fluids that do not work together. This avoids vane sticking or faster wear.

Predictive Maintenance and Monitoring

Daily: Look for leaks outside, strange sounds, or too much heat. Weekly: Check suction pressure and output flow. Monthly/Quarterly: Run vibration checks, thermography, and oil particle counts.

Troubleshooting Common Vane Pump Issues

Diagnosing Reduced Performance

Low flow often comes from worn vanes, scored cam ring, too much clearance, or blocked inlet. Cavitation sounds usually mean low NPSH or air getting in.

Resolving Excessive Noise and Vibration

Fix cavitation by raising inlet pressure or lowering fluid temperature and viscosity. Mechanical noise may need realignment, new bearings, or rotor balancing.

Correcting Leaks and Contamination Ingress

Switch to better shaft seals. Add extra wipers. Make sure covers and flanges have correct torque.

Frequently Asked Questions (FAQ)

Q: How do vane pumps compare to gear or piston pumps?

A: Vane pumps offer smoother flow and quieter operation than gear pumps, while being simpler and less expensive than axial piston pumps for medium-pressure duties.

Q: What causes vane sticking in hydraulic vane pumps?

A: Contaminated fluid, varnish buildup, improper viscosity, or prolonged low-flow operation can cause vanes to stick in their slots.

Q: Can vane pumps run dry?

A: Standard carbon-graphite vane models offer limited dry-run capability; metal-vane versions require fluid for lubrication.

Q: What is the typical service life of a quality vane pump?

A: With proper fluid maintenance and filtration, 10,000–20,000 hours is common in industrial service.

Procurement Opportunities for Hydraulic Vane Pumps

Purchasing managers, procurement specialists, equipment buyers, and technical buyers seeking dependable hydraulic vane pumps can source direct-replacement and high-performance models fully interchangeable with major brands including Vickers, Denison (Parker), Yuken, Tokimec, Rexroth, and Eaton. POOCCA manufactures and supplies OEM-equivalent single, double, and triple vane pump configurations (T6/T7 series, PV2R, V/VQ, 25VQ/35VQ/45VQ equivalents, and more) at competitive factory-direct pricing, supported by large inventory, rapid global shipping, full customization capability, and a standard 12-month warranty. With over two decades of specialized production experience and exports to more than 120 countries, POOCCA delivers reliable, cost-effective hydraulic solutions tailored to demanding industrial and mobile applications. Contact the POOCCA team today to request technical datasheets, obtain quotations, discuss custom configurations, or arrange evaluation samples to optimize procurement decisions and enhance system uptime.