Introduction to Hydraulic Vane Pumps

Overview

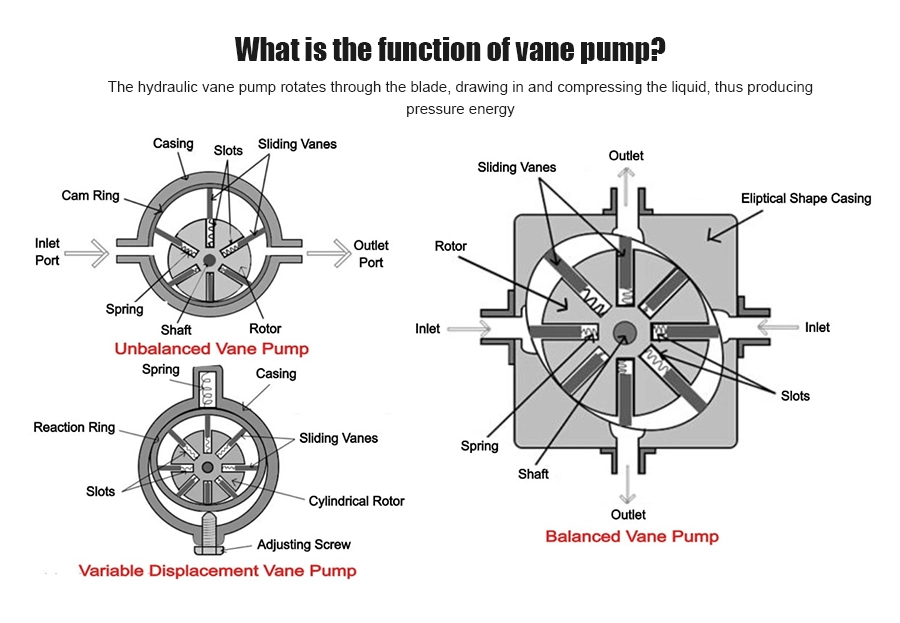

Hydraulic vane pumps are a type of positive displacement pump used in lots of industrial jobs. Their main task is to push hydraulic fluid through a system with spinning vanes inside a grooved rotor. These pumps are super flexible, handling all sorts of fluids like oil, water, and even air with ease, gosh.

The way they work is pretty cool. An off-center rotor sits in a hollow space. When it spins, the vanes slide in and out of their slots to touch the pump’s outer wall. This motion makes spaces that grow and shrink. Those spaces pull fluid in and push it out, creating a steady flow and pressure.

These pumps are handy for all kinds of tasks, like lifting heavy stuff, moving things around, or building fluid pressure. Their tough build fits into fields like construction gear, farming tools, and car systems, to boot.

Types of Hydraulic Vane Pumps

Fixed Displacement Vane Pumps

Fixed displacement vane pumps send out the same amount of fluid each turn. They’re great for jobs needing a steady stream. Plus, their simple setup makes them reliable and easy to care for.

Variable Displacement Vane Pumps

Variable displacement pumps let the flow change based on the system’s needs. This nifty feature saves energy when the load is light, cutting down on power use.

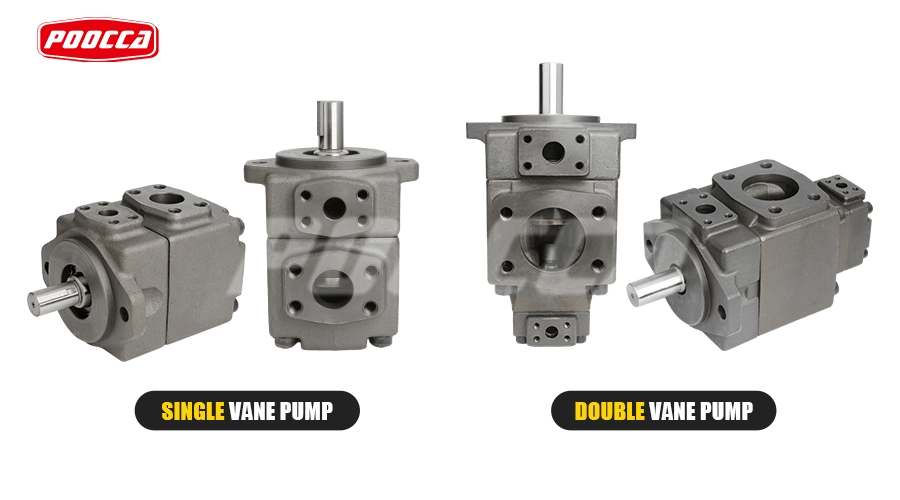

Single vs. Double Vane Configurations

There are two main types of HVPs: single stage and double stage. Single stage pumps handle high pressure but move less fluid. Double stage pumps move more fluid but work at lower pressures. Choosing between single or double depends on the pressure and flow needed for the setup.

How are Hydraulic Vane Pumps Used in Industrial Applications?

From running big machines to keeping factory work smooth, hydraulic vane pumps play a huge role in all sorts of tasks.

These positive displacement pumps use a spinning vaned rotor to create fluid pressure. They’re often found in places needing constant fluid flow, like material handling or machine tooling jobs.

They shine in gentle settings, like lubrication systems, and tougher spots, like clamping tasks in injection molding machines. Often, HVPs work with hydraulic cylinders. The pump builds pressure to move the cylinder piston back or forth. This team-up is common in construction rigs like excavators or farm tools like harvesters.

Plus, their ability to stay steady during long runs makes them a solid pick for power generation systems where breakdowns aren’t an option.

Advantages and Disadvantages of Hydraulic Vane Pumps

Hydraulic vane pumps are positive displacement pumps used widely in industrial work. They come with some fab perks:

- Great efficiency

- Small, tidy size

- Handle lots of different pressures and flows

- Run quietly

- Give smooth flow with hardly any ripples

But, they’ve got some downsides, too:

- Don’t last forever

- Cost a bunch upfront

- Dirt can harm them due to tight inner spaces

Even with these flaws, their strong points make them a top choice compared to other pump styles.

Commonly Used Components in Hydraulic Systems

In a hydraulic setup, several parts work together to get the job done. The main pieces include:

- Pumps: Piston, gear, and vane types. Vane pumps often push out more fluid than piston or gear pumps and work well in many tasks.

- Cylinders: Turn fluid power into straight-line movement.

- Valves: Control direction, pressure, and flow.

- Filters: Clear out junk from the hydraulic fluid.

- Reservoirs: Hold hydraulic oil.

- Hoses & Fittings: Link all the parts safely.

Picking parts that work well together keeps the system running smoothly for ages.

FAQs

What are hydraulic vane pumps, and how do they work?

Hydraulic vane pumps are positive displacement pumps that move hydraulic fluid with spinning vanes. These vanes slide in and out of slots on a rotor, making a pumping motion. This creates a steady fluid flow with high efficiency.

Where are hydraulic vane pumps commonly used in industrial applications?

These pumps show up in industrial machines, material handling tools, car manufacturing, injection molding setups, and power generation systems. They provide steady hydraulic power for all kinds of jobs.

What are the advantages of using hydraulic vane pumps in industrial applications?

These pumps offer high efficiency, quiet running, a small build, and the ability to handle different pressures. They’re also sturdy and keep up steady work even during long hours.

How do hydraulic vane pumps contribute to energy efficiency in industries?

Vane pumps give a smooth, even flow of hydraulic fluid. This cuts energy waste from pressure ups and downs. Their smart design lowers heat buildup and power use, saving cash in industrial work.

Looking for Hydraulic Vane Pumps Supplier in China? Contact POOCCA for Best Offering

POOCCA Hydraulic (Shenzhen) Co., Ltd., started in 2006 with offices in Hong Kong, Guangdong, Jiangsu, and Zhejiang provinces, is a full-service hydraulic company focused on creating, building, fixing, and selling hydraulic pumps like gear pumps, piston units, motors, and valves.

With over 26 years in the game, POOCCA has built strong ties with dealers in more than 75 countries, including the United States, Indonesia, and Brazil. They ship out around $16 million in goods each year thanks to their trusted name for quality items like Parker T6/T7 series vane units or Yuken PV2R series double setups—perfect for small, dual-purpose systems.

Their modern factory covers more than 8,000 square meters, packed with adaptable machining tools, CNC grinders, and automatic checking gear. This ensures they craft precise parts for fields like metallurgy or injection molding.

For custom fixes backed by know-how from over 18 engineers, reach out to POOCCA today for solid supply chain help on all your hydraulic needs—including top-notch hydraulic vane pumps at fair prices.