Introduction

Fluid-handling systems are essential in countless industries, from manufacturing and construction to transportation and energy. Among the many pump technologies available, two stand out for their performance, versatility, and reliability: gear pumps and vane pumps. These positive displacement (PD) pumps offer distinct advantages while also sharing several beneficial characteristics that make them ideal choices for a wide range of applications.

Pumps as Essential Fluid-Handling Machines

Pumps are an integral part of everyday life. They are machines that move fluids and produce hydraulic energy. As fluid properties have become more complex—ranging from highly viscous oils to volatile chemicals—pump designs have evolved to meet the demands of modern industry.

Positive Displacement (PD) Pumps as a Standout Technology

Over time, one pump technology has stood out against the others — positive displacement (PD). PD pumps operate by pulling in fluid, trapping a fixed amount within a chamber and then forcing it out into a discharge pipe. Because of their design, PD pumps tend to have better flexibility than alternative pumping technologies when handling pressure and flow variations found in continuous or intermittent-type processes.

The Basics

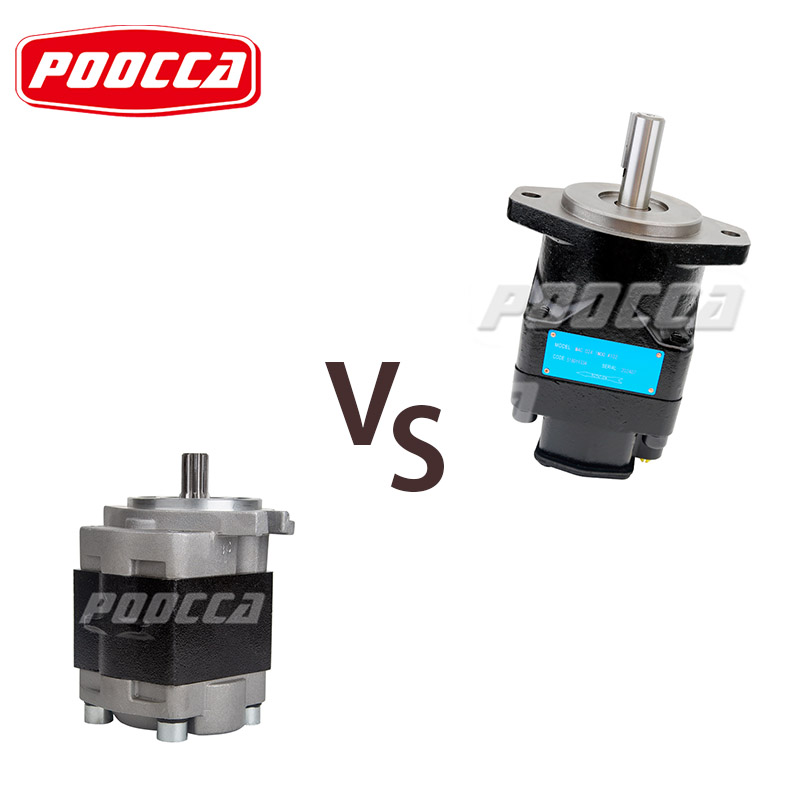

Gear Pumps: External and Internal Types

Gear pumps create flow by pushing liquid through a mesh of teeth between two rotating gears. A drive shaft moves one gear, and that motion moves the other gear. External gear pumps use two separate shafts to support two interlocking gears, which form a mesh at the center of the pump to move fluid along. In contrast, internal gear pumps consist of two interlocking gears of different sizes—a smaller idler inside a larger rotor—with an off-center configuration that creates cavities for fluid transfer.

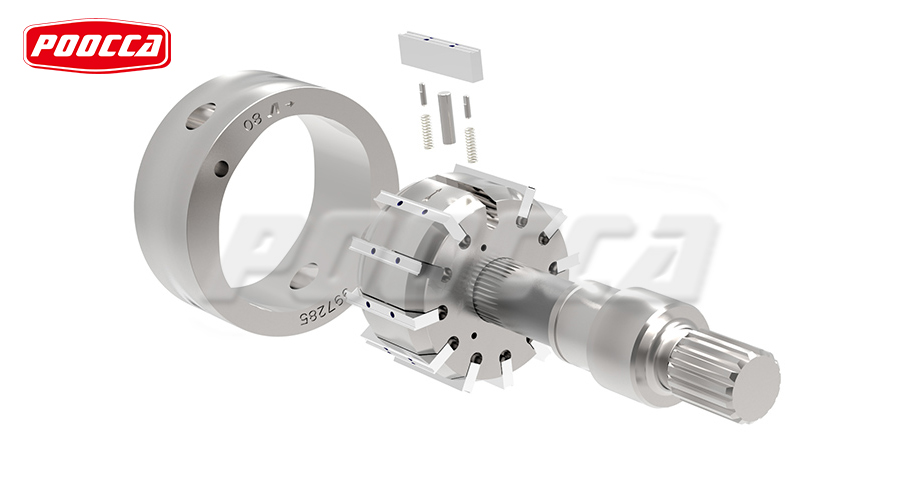

Sliding Vane Pumps: Design and Operation

Sliding vane pumps feature a rotor with vanes that slide into and out of it as the rotor turns. This sliding motion creates chambers into which the liquid flows, and as the rotor turns, the liquid is moved to the outlet where it is discharged as the pumping chamber is squeezed down. Each revolution of the rotor displaces a constant volume of fluid with little chance for slippage, which is the very essence of a PD pump.

Gear Up — The Pros of Gear Pumps

Less is More: Parts and Maintenance

Regardless of configuration, gear pumps do not have many moving parts. Operators do not have to stockpile extra components in case of failure as there are only so few to evaluate. During maintenance shutdowns, gear pump operators only have a few components to evaluate and service. Should a component, such as a gear, fail, operators simply have to open the pump, replace the part and put it back online.

Robust for High Temps, Viscosities

Gear pumps are usually made from cast iron or stainless steel, but can also be constructed using composites or alloys like ductile iron. These materials allow them to handle corrosive fluids such as sulfuric acid or sodium hydroxide. Temperature performance is a key attribute for gear pumps. Because of their robust nature, gear pumps can successfully operate in temperatures as low as -112°F (-80°C) and process fluids with temperatures as high as 800°F (425°C).

The interlocking gears can reliably accept fluids as low as 5 centipoise (cP) or as high as 1,000,000 cP. This makes them ideal for handling everything from solvents to heavy adhesives. Tight internal clearances further enhance their ability to manage aggressive liquids containing dissolved solids.

Sliding Through — The Pros of Sliding Vane Pumps

Self-Adjusting to Wear, Longer-Lasting Components

Sliding vane pumps leverage non-contacting rotating components that avoid material wear and sustain flow rate capacity. The contacting elements are dynamically actuated vanes, that self-adjust for wear throughout the life of a pump. This allows a used pump to sustain the same performance achieved by a brand-new pump.

Their symmetrical between-bearing support design reduces shaft deflection and fatigue. The sealing surfaces are also immediately adjacent to the bearings, making them stationary and ensuring longer seal life.

Functional Benefits

By their design, sliding vane pumps do not have metal-on-metal contact. Without this form of contact, sliding vane pumps can run dry without galling or adverse effects on pump life. They can self-prime even when starting empty.

The vacuum suction capacity of a sliding vane pump is also noteworthy. The pump has high suction lift to 25 feet (8.3 m), making it suitable for underground storage tanks or top-offloading scenarios.

Sliding vane pumps also require no self-lubrication so both lubricating and non-lubricating liquids can be handled equally well. They perform reliably under cavitating conditions with multi-phase mixtures like crude oil or condensate.

Fit to Be Equals

Shared Benefits of Gear and Vane Pumps

Flexibility

Both gear and sliding vane pumps excel in fluctuating systems, offering operational flexibility far superior to centrifugal designs that rely on narrow efficiency points.

Performance Range

Gear and sliding vane technologies allow for a wide range of properties, including viscosity variance from ultra-thin solvents up to thick adhesives or food products like chocolate.

Sealing Options

Gear and sliding vane pumps also feature flexible sealing options, including packed glands, single/double mechanical seals or seal-less magnetic drives—ideal for leak-sensitive environments.

Materials

Both technologies offer multiple material configurations such as cast iron, ductile iron or stainless steel. Jacketed designs are also available for temperature-sensitive materials like asphalt.

Conclusion

Choosing between gear and vane pumps depends on specific application requirements such as fluid type, system layout and operational priorities. Each offers unique strengths—gear pumps provide rugged simplicity with broad chemical compatibility while sliding vane models deliver sustained performance with minimal maintenance over time. Their shared benefits make either choice reliable across diverse industries.

FAQ

What is the main difference between gear and sliding vane pumps?

Gear pumps use intermeshing gears while sliding vane pumps use self-adjusting vanes within a rotor chamber.

Can both types handle high-viscosity fluids?

Yes. The interlocking gears can reliably accept fluids as low as 5 centipoise (cP) or as high as 1,000,000 cP. Sliding vane models handle up to 22,500 cP efficiently.

Are these suitable for dry-running applications?

Only sliding vane pumps can run dry safely due to their non-metallic contact design.

Do they require frequent maintenance?

No. Maintenance is also easy to perform on a gear pump, while vanes in sliding models auto-compensate over time.

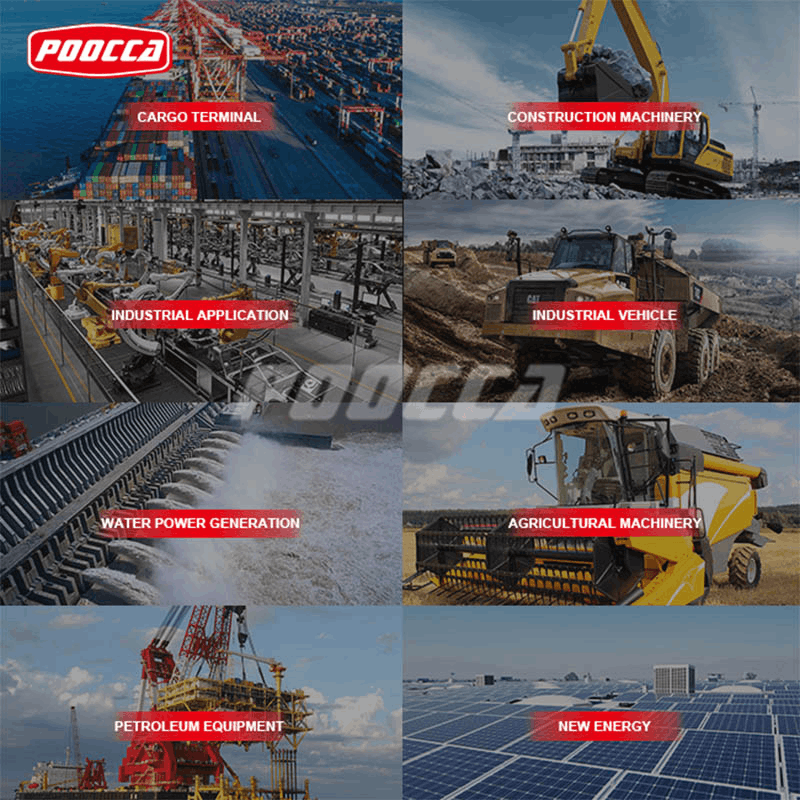

Which industries use these technologies?

They’re widely used in manufacturing plants, tank trucks, petroleum facilities and food processing operations.

POOCCA | Your Trusted manufacturer for Gear and Vane Pumps

POOCCA Hydraulic (Shenzhen) Co., Ltd. was established in 1997, offering decades-long expertise in hydraulic solutions including gear and vane pump systems.

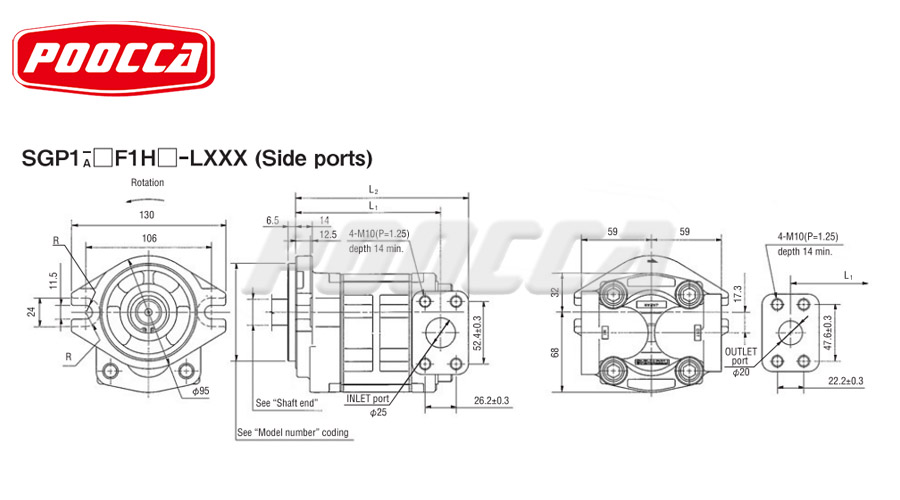

We are a comprehensive hydraulic service company specializing in the research and development, manufacturing, maintenance and sales of hydraulic pumps. Our product line includes high-performance models like Ronzio Z3 Series Gear Pump featuring pressure-balanced bushing blocks with axial compensation capability for high volumetric efficiency up to 95%.

With over 300 skilled professionals—including 18 technical experts—we provide tailor-made solutions across industries such as construction machinery, injection molding equipment, agriculture systems and more. Contact POOCCA for more info and instant quote.