Hydraulic motors act as main parts in fluid power systems. They change pressurized fluid energy into steady mechanical rotation. Parker hydraulic motors stand out because of their careful engineering, strong build, and wide use in tough fields. This close look explains the basic ideas behind hydraulic motors, the key part fluid power plays, and the special qualities that make Parker solutions a top pick for industrial and mobile machines.

Introduction to Hydraulic Motors

What is a Hydraulic Motor?

Hydraulic motors work as actuators. They turn hydraulic energy—usually from pressurized fluid—into mechanical energy. This creates turning motion and torque. Pressurized fluid pushes on inner parts like gears, vanes, or pistons to create output. These motors fit easily into hydraulic circuits. There, pump flow sets the turning speed, and system pressure sets the torque.

Hydraulic motors do well in closed-loop or open-loop setups. They give better power density than electric options, especially with heavy loads or changing conditions. They provide steady force with very little energy waste and less wear over long times.

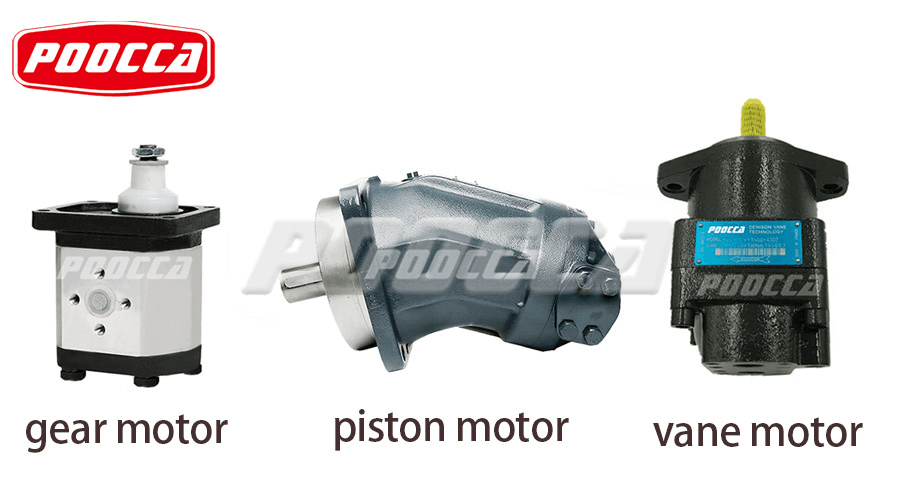

Common types include gear motors for small, low-cost uses; vane motors for smooth, medium-torque work; and piston motors for high-torque, high-pressure needs in big equipment. This range allows exact motion control in agriculture, manufacturing, construction, and robotics.

Importance of Hydraulic Motors in Fluid Power

Hydraulic motors connect fluid power to mechanical output. They allow exact torque and speed control that many electric systems cannot match. They perform best in cases that need steady high torque at low speeds, like running heavy machines or winches.

In fluid power systems, hydraulic motors offer natural benefits in torque control through fluid management. This often removes the need for extra gearboxes. Their strength under very high pressures and changing surroundings ensures reliable work in mobile and fixed setups.

Durability stays a main feature. Designs can handle sudden loads, dirt, and extreme temperatures while keeping good efficiency.

Overview of Parker Hydraulic Motors

Parker hydraulic motors provide excellent performance with modern engineering and tough build. They come in gear, vane, and piston types. These motors meet different needs, from high-torque heavy jobs to exact speed control.

High-pressure ability keeps output steady. At the same time, top materials and careful making fight wear in rough places like construction areas, farm fields, and material handling sites. Better efficiency cuts energy waste and helps lower running costs.

Customization choices cover different displacements, mounting ways, and control add-ons. New developments add electronic feedback for live watching and checks. This helps with predictive maintenance and system improvement.

Types of Parker Hydraulic Motors

Bent Axis Motors

Bent-axis designs have a slanted cylinder block compared to the drive shaft. This allows better efficiency and power density. These motors manage high pressures—often more than 450 bar—and give high speeds with large torque.

Applications cover excavators, industrial presses, and farm machines that need small, strong solutions. New materials cut leaks. At the same time, better shape improves volumetric efficiency and lowers noise.

Strong build allows work over wide temperature ranges. Built-in check features support predictive maintenance. This reduces downtime and total costs.

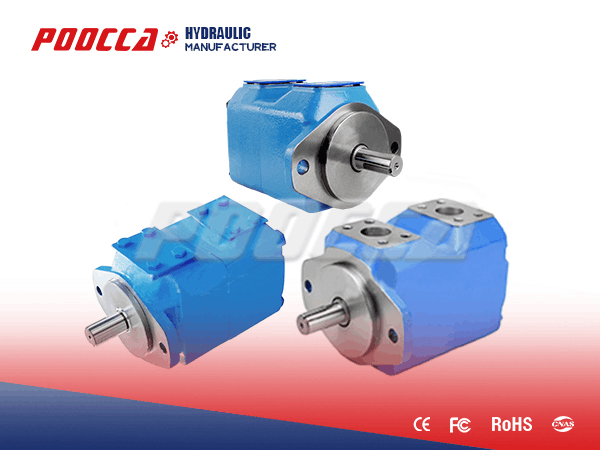

Vane Motors

Vane motors use sliding vanes inside an off-center rotor to create torque. They give smooth work and adjustment under changing loads. They do well in uses that need higher speeds with medium torque, such as conveyors, machine tools, and material handling gear.

Steady performance over wide pressure and displacement ranges allows exact control. Wear-resistant vanes and good sealing increase service life. Bi-directional ability adds flexibility in complex circuits.

New versions include smart watching for pressure, temperature, and speed. This helps IoT connection and fits with Industry 4.0 ideas.

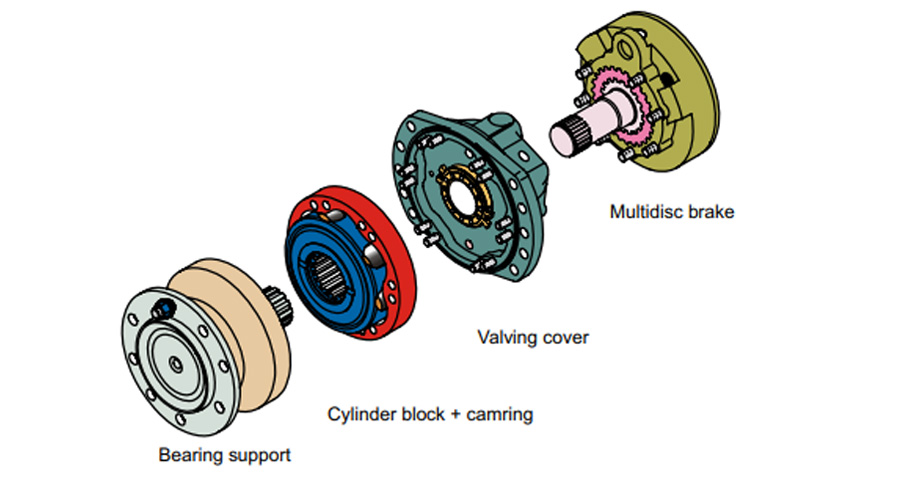

LSHT Motors

Low-speed high-torque (LSHT) motors create large torque at very low speeds without gear reductions. They suit controlled, heavy-load motion in rough settings.

New displacement designs and materials boost efficiency and strength under changing loads. Digital controls allow close tracking of performance for predictive plans.

These motors see wide use in mining, agriculture, and oilfield gear. They work with eco-friendly fluids and high volumetric efficiency helps sustainable work.

Key Features of Parker Hydraulic Motors

Efficiency and Performance

Parker hydraulic motors reach very good efficiency with fresh engineering. High volumetric efficiency—often above 90%—makes the most of energy change from fluid to mechanical output.

Better torque at low speeds ensures smooth work with heavy loads. Thermal stability keeps steady performance over extreme temperatures through good heat spread.

Wide fluid match, including bio-based types, meets environmental rules. Long service times come from wear-resistant parts and careful build.

Durability and Reliability

Strong sealing systems stop leaks and dirt, even under high pressure. Corrosion-resistant materials handle tough surroundings.

Better bearings handle radial and axial loads well. Thermal management new ideas prevent overheating in long use.

Solid build fights shock, vibration, and stress. This ensures longer life in hard settings.

Innovative Design Technologies

Advanced Gerotor Technology

Precision gerotors give smooth power with less leakage. This raises energy efficiency by up to 15% over older designs.

Optimized Flow Channels

Machined channels cut turbulence. They improve fluid flow and lower heat for steady performance.

Improved Seal Materials

Advanced seals work well from -40°F to 250°F. They stretch maintenance times a lot.

Integrated Anti-Cavitation System

It stops vapor bubble creation. This cuts wear and improves long life under heavy loads.

Modular Construction Design

Interchangeable parts allow quick customization and easy fixes.

Applications of Parker Hydraulic Motors

Industrial Applications

Material Handling Equipment

Precise torque and control run conveyors, lifts, and automated systems in warehouses and factories.

Machine Tools

Steady speed and torque help lathes, mills, and grinders for accurate work.

Injection Molding Machines

Repeatable motion keeps precise clamping and injection at high pressures.

Presses

High power density runs metal forming and stamping well.

Mining and Drilling Equipment

Durability deals with rough conditions while keeping efficiency.

Mobile Equipment Applications

Excavators get exact control in digging and lifting. Wheel loaders give smooth torque. Agricultural machinery keeps steady work in harvesting. Forestry equipment manages heavy loads reliably. Municipal vehicles work well in bad conditions.

Agricultural Applications

Tractor attachments get steady power for soil work. Harvesting equipment handles crops well. Irrigation systems give even water spread. Material handling lifts heavy loads. Crop sprayers put inputs on accurately.

Real-World Examples of Parker Hydraulic Motors in Use

Case Study: Parker Motors in Industrial Automation

In fast packaging lines, Parker motors run conveyor systems with little friction loss. This allows matched operations. Results show higher output, less energy use, and lower downtime.

Frequently Asked Questions (FAQ)

Q: What are Parker hydraulic motors used for?

Parker hydraulic motors support heavy-duty and medium-duty applications requiring precise control and reliable power in hydraulic systems.

Q: What features do Parker hydraulic motors offer?

High volumetric efficiency, smooth low-speed operation, high starting torque, and extended service life characterize these motors.

Q: Which applications suit Parker hydraulic motors best?

Construction, agriculture, industrial machinery, and mobile equipment benefit from their high-pressure capabilities and durability.

Ready to Elevate Operations with Superior Hydraulic Solutions?

Procurement professionals, equipment manufacturers, OEMs, system integrators, and industrial operators looking for reliable, high-performance hydraulic motors gain significant advantages from components that deliver industry-leading efficiency, exceptional durability, and broad fluid/system compatibility.

POOCCA serves as a dedicated manufacturer, supplier, and factory of hydraulic solutions, offering extensive in-stock availability of Parker-equivalent motors, competitive factory-direct pricing, and consistently verified quality. For more Parker hydraulic motors, please contact POOCCA, which maintains strong inventory and provides better price and quality.

Explore comprehensive hydraulic motor options today to optimize fluid power performance across industrial, mobile, and agricultural applications.