Hydraulic motors hold a vital spot in turning hydraulic energy into mechanical power. They help run heavy machines in many fields. These tools prove key for jobs that need exact control, strong torque, and steady work in tough settings. Among the main kinds, three big ones stand out: gear motors, vane motors, and piston motors. Each kind brings clear benefits. This makes them fit for certain work needs.

How Are the Types of Hydraulic Motors Classified?

Hydraulic motors fall into two broad groups by how they run: high-speed, low-torque (HSLT) and low-speed, high-torque (LSHT). HSLT motors shine in cases that call for quick spins with fair force. Examples include conveyor belts or simple drives. On the other hand, LSHT motors give big power from small builds. They cut down shakes and sounds. This grouping helps a lot in tight spaces, like mobile gear. Here, good use of energy and quiet runs matter most.

LSHT motors, especially, offer great torque in a small package. They allow strong outputs without huge parts. Their slow-speed skills suit jobs with big loads, such as winches or excavators. By matching motor picks to these groups, systems gain better energy use. They also see less wear on nearby parts. Things like fluid thickness and system pressure shape how they perform. This shows why custom groups matter in hydraulic work.

Rating Hydraulic Motors

Checking hydraulic motors uses main measures to see if they fit certain jobs. Displacement, shown in cubic centimeters per revolution (cc/rev) or cubic inches per revolution (in³/rev), tells the fluid amount needed for one shaft turn. Bigger displacement links to more torque chance. Smaller values aid quicker speeds.

Torque ratings, given in Newton-meters (Nm) or inch-pounds (in-lb), measure the twist force output. These numbers affect how much load they can handle. Higher torque lets them tackle tough twist jobs well. Efficiency ratings, often over 90% for top models, show how well energy turns to work. This cuts heat and fluid waste.

Rules from groups like the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO) keep tests and specs the same. SAE J745, for example, sets rules for mobile uses. ISO 8426 covers vane motor checks. Sticking to these marks ensures parts work together. It also builds trust in varied hydraulic setups. Good rating checks stop bad matches. This helps systems last longer and keeps costs down.

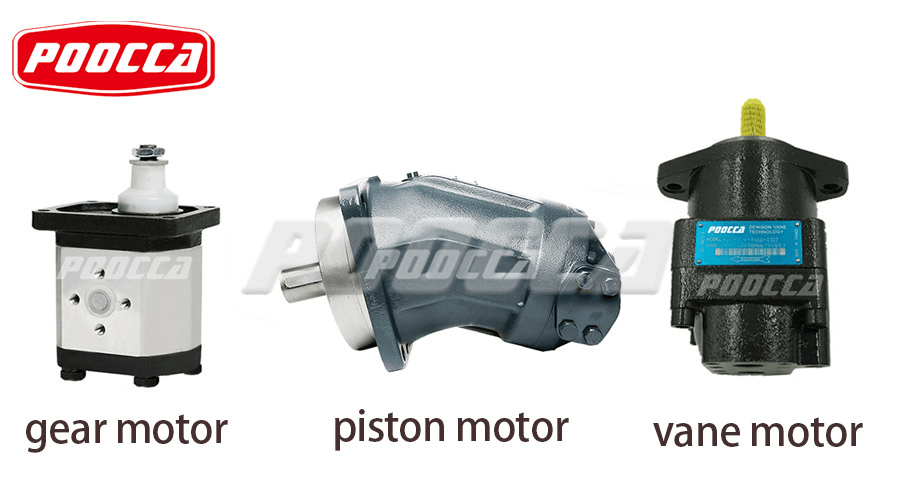

Gear Motors

Gear motors form the basic kind of hydraulic motor. They have a simple build and tough makeup. They include an idler gear and a driven gear. These motors have an output shaft locked to the driven gear for straight power move. High-pressure fluid goes in one side of the gears. It flows through the case to the outlet port. Gears that mesh make a seal. This stops backflow and keeps turns one way.

The draw of gear motors comes from their low start cost. They also handle dirt well. This makes them tough in dusty or messy spots. Strength comes from few moving bits. This lowers break risks and care needs. They work at pressures up to 250 bar. Speeds range from 500 to 3,000 RPM. This makes them handy all-rounders.

Common uses cover fans for cooling, screw conveyors in moving stuff, and dispersion plates in mixing gear. In factory settings, gear motors run side tasks where steady, fair torque works. Their small size and two-way skill boost fit in auto lines. For fields that want cheap yet solid options, gear motors give steady worth.

New steps in gear tooth shapes, like involute styles, have cut noise and thumps. This makes runs smoother. Materials such as hardened steel boost wear fight. This lengthens care gaps. When paired with variable flow pumps, gear motors shift fast to load shifts. This raises energy savings in changing needs.

Vane Motors

Vane motors stand out with a clever rotor-vane setup in an off-center bore. The rotor links to the output shaft. It holds sliding vanes that stretch out from spin force and fluid push. Incoming hydraulic fluid fills vane spaces. This builds turn force as vanes press the housing. This setup gives smooth, low-shake runs even at changing speeds.

Main pluses include easy build that allows quick take-apart and fix. They also have low noise levels—often under 70 dB. Vane motors excel in giving high start torque at slow speeds. This fits exact place tasks. Pressures up to 175 bar and displacements from 10 to 500 cc/rev meet many mid-duty needs.

Farm machines, like harvesters and tractors, often use vane motors for steering and tool drives. In injection molding, screw-drive parts gain from their steady torque give. Marine uses, including winches on small boats, use their small size and good work in on-off runs.

Current vane motors use balanced builds to cut side loads. This extends bearing life. Vanes that adjust themselves handle wear. They keep volume efficiency over time. For systems in heat changes, special vane stuff fights swell or breaks. This ensures steady work from -20°C to 80°C.

Piston Motors

Piston motors provide the top of hydraulic motor tech. They split into radial and axial setups. Their piston-cylinder layouts give great power thickness, efficiency, and control. They meet high-work demands.

Radial-Piston Motors

Listed under LSHT, radial-piston motors place pistons at right angles to the output shaft. They often form a star pattern around a cam or off-center part. Fluid pressure pushes pistons out against the cam. This makes torque via roll or slide touch. This shape gives very high torque at slow speeds. Ratios reach up to 1:100 for speed cuts.

Pluses include smoother slow-speed runs and higher output torques. These often top 10,000 Nm. Their built-in gear effect removes need for outside reducers. This saves room and weight. Pressures up to 450 bar and displacements over 10,000 cc/rev make them best for heavy lifts.

Ground drilling rigs use radial-piston motors for exact, high-force push. Winches on offshore platforms and cranes in build sites depend on their stop torque for safe load hold. Caterpillar drives in dragline excavators show their part in huge earth moves. Here, trust under big loads is a must.

Axial-Piston Motors

Axial-piston motors line pistons parallel to the shaft in a turning cylinder block. A swashplate or bent-axis tool turns straight piston moves into spins. This allows variable displacement via angle shifts. This gives great speed and torque change, from 0 to 5,000 RPM.

Benefits cover high speeds, efficiencies near 98%, and small power-to-weight ratios. They run at pressures up to 420 bar. They handle ongoing tasks with little heat rise. Fixed or variable types fit steady and shifting uses.

Winches in logging work, build loaders, and shipyard cranes use axial-piston motors for flexible power. In making, they run rotary tables with tiny precision. This aids auto trends.

Choosing the Right Hydraulic Motor

Picking the best hydraulic motor starts with deep look at job needs. Work measures—temps from -40°C to 100°C, speeds up to 4,000 RPM, pressures over 400 bar, and torque wants—set the type. Gear motors fit cost-wary, dirt-heavy spots. Vane motors favor low-noise exact work. Piston motors lead in high-power cases.

Ease of setup sways picks. Flange-mounted choices make upgrades simple. Field rules, such as ISO 3019-1 for mounting, ensure fit. Dirt risks call for strong filters. Bits speed wear in all kinds.

Working with skilled hydraulic experts eases choices. They add simulations for system fit. Full-life costs, like care and energy, often favor tough piston types. This holds even with higher start spends.

FAQ

What is the primary difference between HSLT and LSHT hydraulic motors?

HSLT motors focus on high turn speeds with lower torque outputs. They suit fast cycle tasks. LSHT motors, in turn, give high torque at lower speeds. They excel in heavy-load jobs like lifting.

How does displacement affect hydraulic motor performance?

Displacement sets torque ability. Bigger volumes make more force per turn but cap top speed. It shapes system size for even flow rates.

Are gear motors suitable for high-pressure environments?

Gear motors manage pressures up to 250 bar well. Yet, piston motors beat them in extremes over 400 bar due to better seals.

What maintenance is required for vane motors?

Regular checks cover vane wear looks and fluid clean. Their easy build allows fast rebuilds, often every 2,000 hours.

Can piston motors operate bidirectionally? Yes, both radial and axial kinds allow reverse via fluid port switch. This enables uses like two-way winches.

How do efficiency ratings vary across motor types?

Gear motors average 85-90% efficiency. Vane motors hit 92%. Piston motors top 95%. This cuts energy loss in tough cycles.

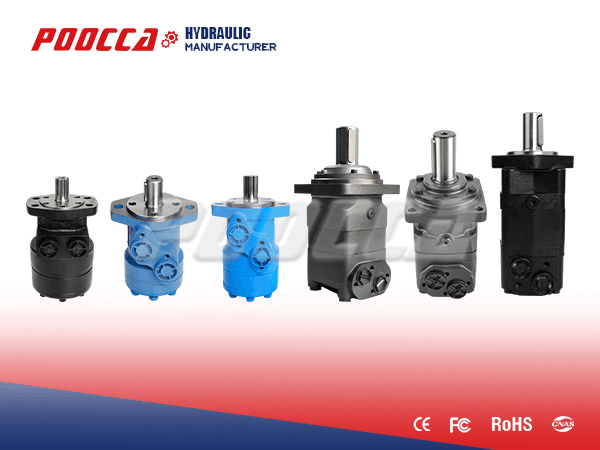

Partner with a Trusted Hydraulic Manufacturer and Supplier for Superior Solutions

Hydraulic systems need exact-made parts to keep top work. As a focused manufacturer and supplier with over 20 years of skill, POOCCA offers OEM-quality hydraulic motors. These include gear, vane, and piston kinds. They also provide full custom services. Factories with advanced CNC tools make trusty swaps for brands like Rexroth, Parker, and Danfoss. This ensures smooth fit. Contact POOCCA today at +86 18927498997 or sales@kamchau.com to talk custom hydraulic motor answers. Ask for quotes or check care help. Boost work efficiency with POOCCA’s factory-direct trust.