Hydraulic pumps stand as vital parts in any mobile or fixed hydraulic setup. Picking the correct pump kind — fixed displacement or variable displacement — can shape not only how well it works, but also power savings, price, and lasting strength. This piece looks at both pump kinds, how they function, usual uses, good points and bad points — and when one kind may fit better than the other.

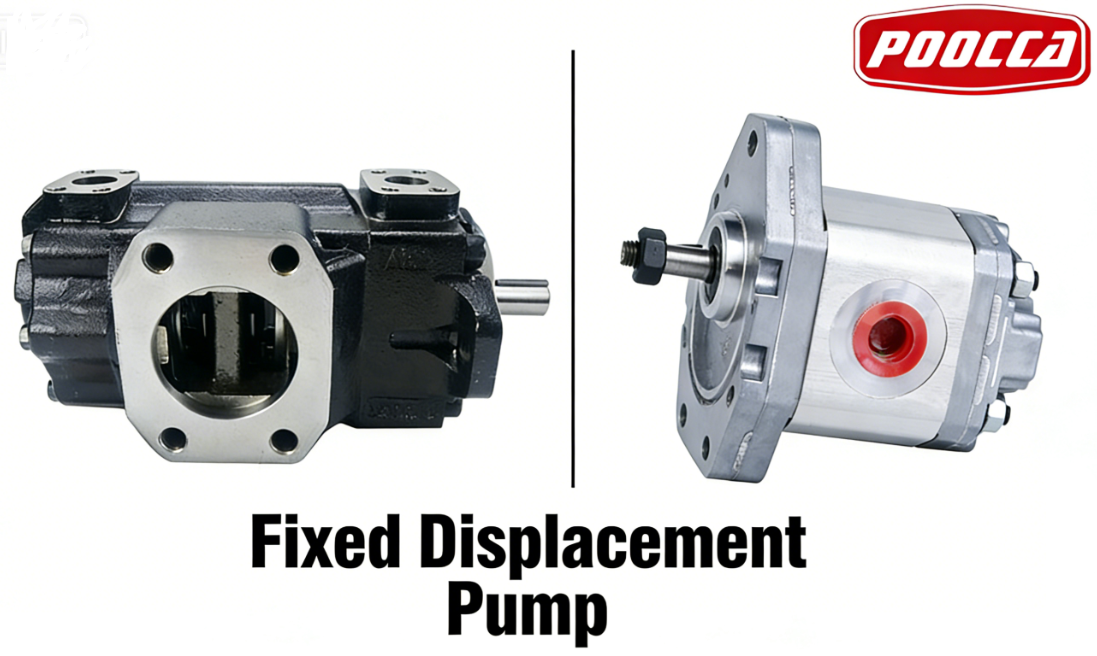

Fixed Displacement Pumps — Simple, Robust, Predictable

A fixed displacement pump pushes the same amount of fluid with every turn. For instance, a “2.8 in³” fixed pump will move that exact oil amount each spin. Inside, fluid gets caught between gear teeth (in a gear pump) or between vanes/pistons and the casing — and this set shape sets the pump’s displacement.

Since its flow stays steady, the sole way to cut down flow when full output isn’t required is to send or release the extra fluid back to the tank. Yet, this release throws away power — mainly if the setup runs at part loads often.

Common Applications for Fixed Displacement Pumps

Fixed displacement pumps work great when the hydraulic system needs a constant, steady flow always. Normal cases include:

Material handling

Machine tools

Conveyors and manufacturing machines

Marine applications

Agricultural equipment

Lubrication systems

Mobile applications using tandem center valves

Pros and Cons of Fixed Displacement Pumps

Pros

Simplicity: fewer moving parts ⇒ simpler upkeep, tough and dependable.

Predictable output: flow stays the same per turn, making system planning easier.

Often less costly at first than complex pumps.

Cons

Not efficient under changing loads: extra flow usually dumped or sent back when full displacement isn’t required → lost power.

Less adaptable: no flow control without relief valves or outside controls.

Possible higher power use in systems with shifting needs.

Variable Displacement Pumps — Flexible, Efficient, Adaptive

A variable displacement pump can change its fluid push based on what the system wants. A typical case is a variable-displacement piston pump: pistons link to a swash plate whose tilt can shift with system pressure, thus changing the volume moved per turn.

When pressure rises in the loop, a pressure compensator pushes the swash plate to lower its stroke tilt. This cuts output flow. On the other hand, when need falls, output can drop — saving power and cutting waste.

Variable displacement vane pumps with like adjustable parts also exist.

Common Applications for Variable Displacement Pumps

Variable pumps shine where load needs shift a lot or change greatly, such as in:

Mobile applications using closed-center valves

Agricultural machinery with changing demands

Mobile service trucks

Snow and ice equipment

Any hydraulic system needing power savings during part-load or idle times

Pros and Cons of Variable Displacement Pumps

Pros

Power savings: output matches need — less wasted fluid flow.

Adaptability: simpler to manage flow/pressure for shifting workloads.

Less heat and fluid strain from unneeded high-flow extra.

Cons

More complex inside — more moving parts, closer fits.

Higher starting cost than fixed pumps.

Needs stricter filtering and care to keep it lasting and stop harm from dirt.

Making the Choice — What to Consider

The pick between fixed displacement and variable displacement must rely on the system’s work cycle, load changes, and future running aims. Here are main points to think about:

Load profile: If flow need stays steady and clear, a fixed displacement pump may be enough. If load shifts (start/stop rounds, changing loads, idle times), variable displacement often comes out ahead.

Energy efficiency / operating cost: For setups that run much at part load or idle, variable displacement pumps cut power and lower losses.

Budget & maintenance constraints: Fixed displacement pumps are simpler and cheaper at start. Variable displacement pumps — though more saving — need better care, filtering, and maybe more skill for fixing.

Space, noise, and heat considerations: Variable displacement pumps can lower waste heat. They may create less waste flow, easing cooling needs.

System design and control needs: If exact control over flow/pressure is wanted (e.g., in mobile hydraulics, shifting loads), variable displacement offers more options.

In many situations, the future cost cuts on power and less waste flow make up for the higher start cost of a variable displacement pump — mainly for machines working under shifting or on-off loads.

Maintenance Best Practices for Hydraulic Pumps

Good care stretches pump life and keeps efficiency, no matter the kind.

Fixed displacement pumps: Regular checks focus on seal health and gear wear. Oil checks spot dirt early. Filter changes every 500 hours stop clogs. Alignment checks avoid shaft strain.

Variable displacement pumps: Need close watch of compensator work and swashplate movement. Use pressure gauges to check changes. Yearly breakdowns look at piston bores for marks. Software updates for electro-controls keep precision.

Universal habits include sticking to viscosity rules, removing air from loops, and noting runtime for planned fixes. Training operators on load caps cuts misuse. Keeping OEM parts speeds repairs.

Following these steps can double service times, boosting system trust.

FAQ

Q: What is the main difference between fixed displacement and variable displacement hydraulic pumps?

A: A fixed displacement pump delivers a constant fluid volume with each revolution, regardless of demand; a variable displacement pump can adjust the volume output according to system pressure or demand.

Q: When is a fixed displacement pump preferable?

A: When a hydraulic system has a consistent, predictable load and flow demand — for example conveyors, lubrication systems, or machinery with stable usage patterns.

Q: Why use a variable displacement pump instead?

A: For systems with varying load or intermittent use — variable pumps save energy, reduce waste flow, and adapt output to actual demand.

Q: Are variable displacement pumps more expensive?

A: Yes. They tend to cost more upfront, require more precise filtration and maintenance, and have more complex internal components.

Q: Can a manufacturer supply both types of pumps?

A: Yes. Companies like POOCCA supply a broad range — including fixed and variable piston pumps, vane pumps, gear pumps — and can often offer both ready-made and customized solutions.

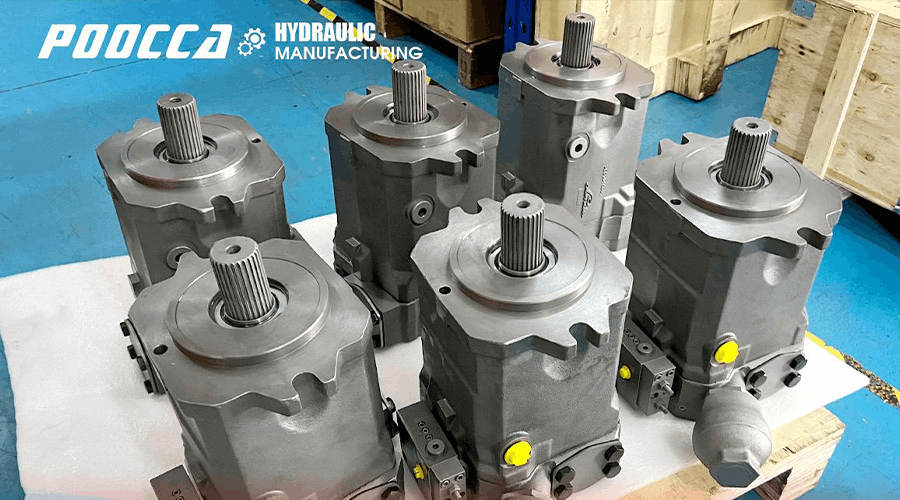

Turnkey Hydraulic Solutions from a Trusted Supplier

For manufacturer and wholesale supplier, plus equipment runners seeking dependable hydraulic parts and custom fits, POOCCA gives a full, factory-direct supply of pumps, motors, valves and more. With over 20 years’ skill, a huge product list, OEM/ODM ability, and worldwide export reach, POOCCA stands ready to meet hydraulic needs across fields — from construction and agriculture to marine, material handling and heavy machinery.

Explore POOCCA’s product lineup and get a quote today to ensure optimal hydraulic performance and long-term reliability.