Hydraulic motors act as key mechanical drivers in fluid power systems. They turn pressurized hydraulic energy from fluid flow into turning mechanical energy. This change allows strong torque at fairly low speeds. So, hydraulic motors fit tough tasks where electric motors might not work well because of power density or setting limits. Pressurized hydraulic oil moves inside parts to make turning. It gives steady work in hard jobs.

These parts see wide use in many fields. That includes construction equipment (such as excavators and loaders), agricultural machinery (like combine harvesters and tractors), forestry equipment, material handling systems (winches and conveyors), and mobile machinery. The skill to make big torque in small sizes helps good power send in hard spots. Those spots cover rough outside areas and high-load cases.

Types of Hydraulic Motors

Hydraulic motors have a few main types. Each fits certain work needs.

Gear Motors

Gear motors have basic build with matching gears that move fluid to make turning. They give steady run, fair efficiency, and low price. They work for tasks needing medium pressure and speed. Gear motors bring solid start torque and last in easy systems.

Vane Motors

Vane motors use sliding vanes in a rotor group inside an off-center cam ring. Pressurized fluid pushes the vanes out. This makes torque by turning. These motors give even work, high start torque, and steady output over a broad speed range. They do well in tasks that need low sound and firm run.

Piston Motors

Piston motors come in axial and radial setups. They use back-and-forth pistons to turn fluid pressure into torque. Axial piston motors often have changing displacement for set speed and torque. Radial piston motors give top high torque at low speeds. These types take high pressures. They also bring top efficiency in hard tasks.

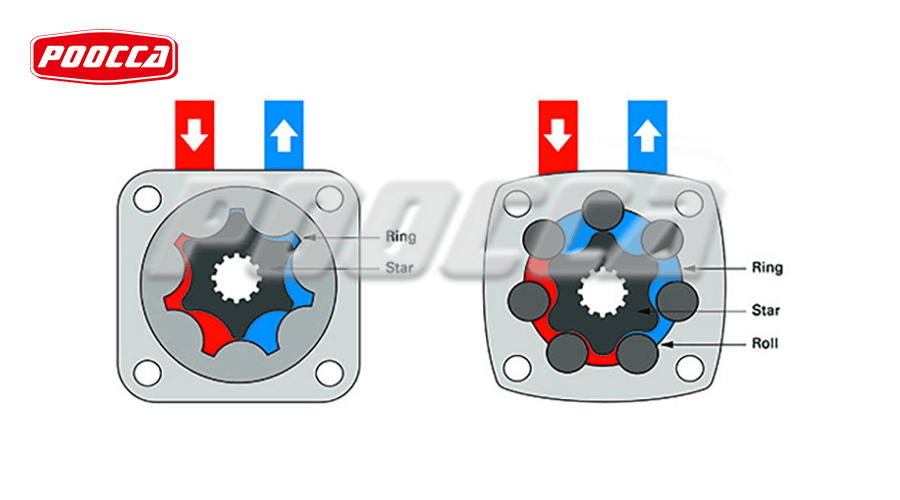

Orbit Motors (Gerotor Motors)

Orbit motors, also known as gerotor or geroller motors, include an inner rotor and outer stator with circling motion. Fluid flow makes the rotor circle and turn. This makes high torque in a small shape. They get used a lot in mobile and factory equipment. Orbit motors bring great low-speed work and strong build.

Working Principle

The basic run of hydraulic motors follows a steady order, no matter the type:

- Fluid Inlet Pressurized hydraulic oil goes into the motor through the inlet port from the hydraulic pump or system.

- Pressure Conversion The coming fluid’s pressure works on inside parts—such as gears, vanes, or pistons—to turn hydraulic energy into mechanical force. Torque output ties right to the pressure gap between inlet and outlet ports.

- Rotational Motion The force moves or pushes parts. This makes the output shaft turn and send power to driven machinery.

- Fluid Outlet Low-pressure fluid leaves through the outlet port. It goes back to the reservoir or system for reuse.

This loop goes on without stop. It allows ongoing turning. Work rate relies on cutting inside leaks and tuning part design for set pressure and flow states.

Advantages and Disadvantages of Different Hydraulic Motor Types

Each motor type shows clear pluses and minuses:

- Gear Motors— Plus points include ease, low cost, and hold to dirt; minus points cover lower work rate at high pressures and fair torque output.

- Vane Motors— They bring even run and good volume work rate; limits include open to fluid dirt and wear on vanes with time.

- Piston Motors— They give high work rate, changing displacement picks, and top power density; downsides hold higher start cost and hard upkeep.

- Orbit Motors— They shine in high torque at low speeds with small size; possible minuses cover lower top speeds than other types.

Selection Criteria for Hydraulic Motors

Picking the right hydraulic motor needs close check of task needs. This makes sure best work, long life, and system fit.

- Torque and Speed Requirements Check the needed torque and turning speed. Gear motors fit low to fair torque tasks. Radial piston or orbit motors do best in high-torque, low-speed cases.

- Operating Pressure Match the motor to system pressure levels. Piston motors take higher pressures well. They suit strong runs.

- Environmental Conditions Think of heat highs, wet, dust, and dirt. Strong closed builds and rust-proof materials boost last in rough spots.

- Space Constraints Check setup sizes. Small picks like gear motors or short orbit motors fit tight areas.

- Cost and Maintenance Balance start spend with long work rate and care needs. Piston motors may cost more at first. But their strong build often cuts full care costs.

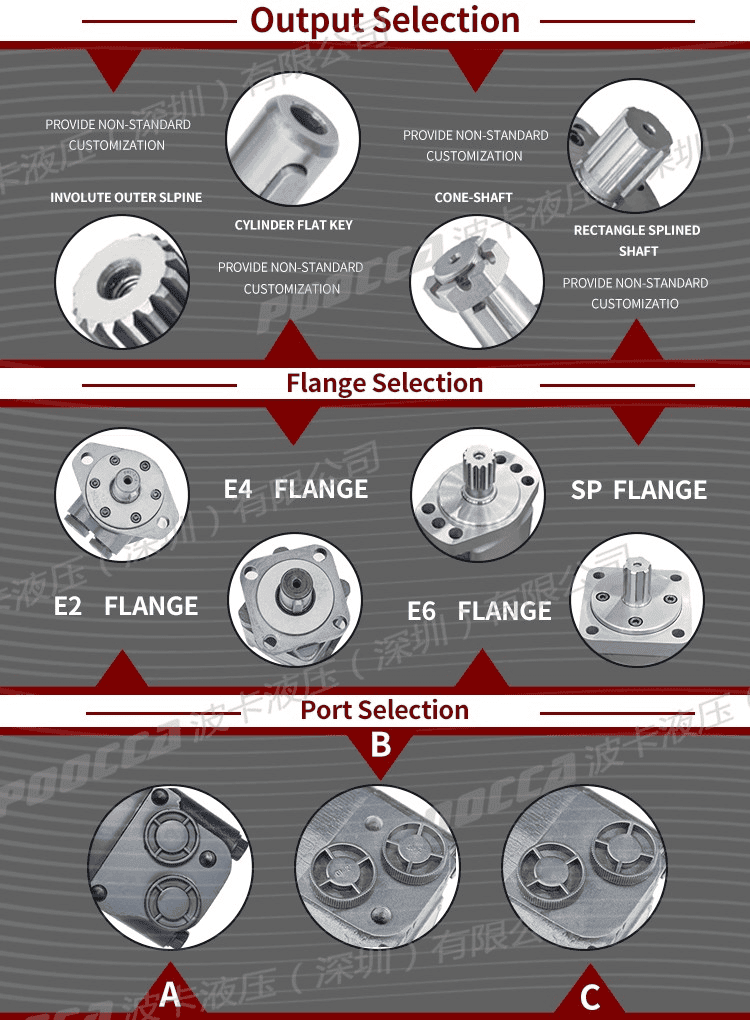

Other points cover fluid match, shaft and mount setups, port types, and displacement span to line with system specs.

Advanced Considerations in Motor Selection

Past main points, things like volume and mechanical work rate affect full system work. Work curves help guess energy loss under changing loads. Fit with changing displacement pumps allows exact control in new hydraulic lines. Sound levels, shake, and heat handle also matter in gear setup.

For mobile tasks, weight and small size get key. Factory setups focus on steady and care times.

Conclusion

Hydraulic motors bring flexible, strong fixes for turning fluid energy into turning motion over many areas. Knowing their run ways and using firm pick points makes sure systems hit top work rate and steady.

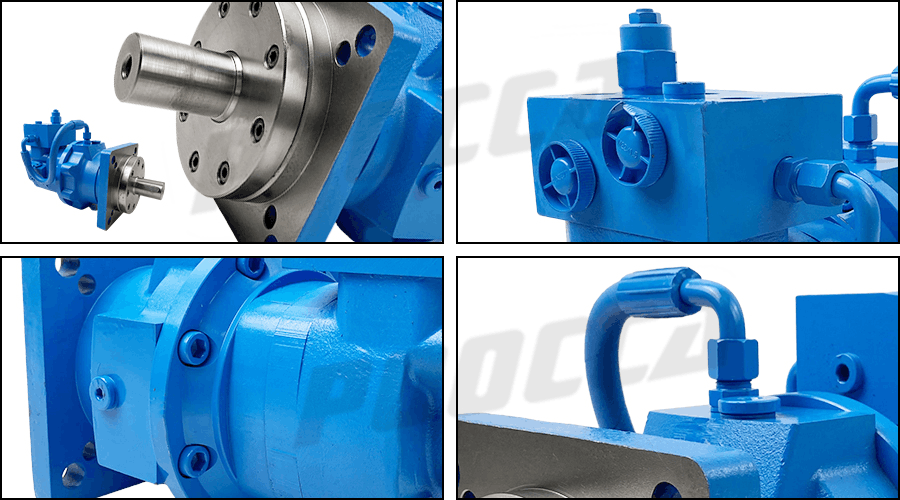

Manufacturers and suppliers seeking high-quality hydraulic motors, including orbit, gear, vane, and piston types with customizable options, can explore offerings from POOCCA. As a manufacturer, supplier, and factory specializing in hydraulic components, POOCCA provides reliable products with competitive performance for industrial, agricultural, and mobile applications. Contact the team for tailored solutions and specifications.

FAQ

What is the primary function of a hydraulic motor?

A hydraulic motor converts hydraulic energy from pressurized fluid into rotational mechanical energy to drive machinery.

How does torque relate to pressure in hydraulic motors?

Torque output depends on the pressure difference between the inlet and outlet ports, with higher differentials producing greater torque.

Which hydraulic motor type is best for high-torque, low-speed applications?

Radial piston motors or orbit motors typically excel in high-torque, low-speed scenarios.

What factors should be considered for environmental suitability?

Temperature range, exposure to contaminants, humidity, and corrosion resistance determine motor durability in harsh conditions.

Why choose piston motors over gear motors in demanding systems?

Piston motors handle higher pressures, offer better efficiency, and support variable displacement for enhanced control.

Partner with a Trusted Hydraulic Motor Manufacturer and Supplier

Equipment manufacturers, system integrators, and industrial suppliers benefit from sourcing dependable hydraulic motors that meet precise specifications. POOCCA, as a leading manufacturer, supplier, and factory, delivers a comprehensive range of hydraulic motors—including orbit, piston, gear, and vane designs—with customizable features, competitive pricing, and reliable performance. Reach out today to discuss project requirements, request quotes, or explore product catalogs for optimized hydraulic solutions. Contact the POOCCA team via email at sales@kamchau.com or WhatsApp at +86 18927498997 to initiate collaboration.