In hydraulic systems, strange noises usually show there are problems underneath that can hurt how well the system works and cause expensive stops in operation. Sounds from pumps and valves can be whining, grinding, or chattering. These often mean issues like cavitation, aeration, or parts wearing out. Fixing these sounds quickly with good checks and care stops small troubles from turning into big breakdowns.

Hydraulic systems give power to big machines in fields like construction, farming, mining, and making things. Pumps and valves are the main parts. Any odd noise needs quick notice. This guide looks at usual noises from hydraulic pumps and valves, what causes them, and simple steps to fix things so everything runs smoothly again.

Hydraulic Pump Noises and Causes

Hydraulic pumps create flow and pressure. But things like dirty fluid, air getting in, or worn parts bring in bothersome sounds. If you ignore these noises, damage speeds up, efficiency drops, and the whole system might fail.

High-Pitched Whining

A sharp, high whining sound often comes from cavitation. This happens when low pressure makes vapor bubbles appear in the hydraulic fluid. Those bubbles burst hard when they hit higher pressure spots. This creates shock waves that slowly eat away at the inside of the pump. Things that start this include blocked inlet lines, dirty filters, fluid that is too thick, or pump speeds that are way too fast.

Aeration makes a close but less steady whining noise. Air slips into the system from loose connections, bad seals, or low levels in the reservoir. This leads to uneven bubble squeezing. Such uneven air spreads wear on parts, dirties the fluid, and hurts seals. Both cavitation and aeration need fast checks to stop the pump from failing too soon.

Metallic Noises

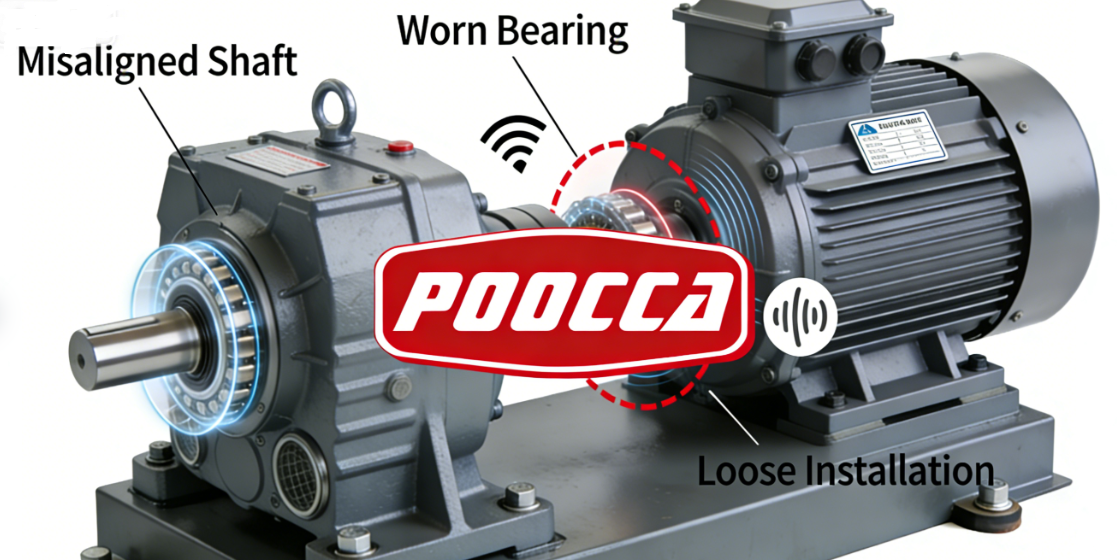

Grinding, roaring, rattling, or whirring sounds, mainly when they come with shakes or hotter temperatures, point to mechanical troubles inside the pump. Drive couplings that are not lined up right pass uneven forces. Worn bearings, gears, or pistons cause metal rubbing on metal. These problems usually come from running for a long time with dirty conditions or wrong setup.

In vane or piston pumps, broken vanes or pistons make knocking or rattling. Gear pumps might grind if gear teeth wear out unevenly. Checking couplings and inside parts often helps spot these issues early.

Chattering

Chattering sounds come from quick changes in pressure or rough flow near the pump inlet. A leaky check valve on the suction side lets fluid flow back. This causes drops in pressure now and then and shakes. Problems with pressure controls or bumpy flow in close pipes add to this annoying sound.

Hissing or Whistling

Hissing usually starts from relief valves letting fluid pass all the time. A relief valve set too low or jammed open lets out pressure when it is not needed. This makes a constant hiss. Uneven whistling shows wrong settings or damage inside the valve. It allows pressure to escape without control.

Troublesome Relief Valve Noises

Pressure relief valves keep systems safe by sending extra flow away. But dirt or wear causes noisy work and possible dangers.

Chattering in relief valves happens when junk stops the valve from closing fully. This leads to fast open and close cycles. Wear from dirt lets small leaks grow into shakes.

A sharp squeal means a stuck valve. It traps pressure and puts stress on the system.

Vibration sounds come from fast flow at the outlet. This makes pulses that echo through the valve body.

Dirty fluid makes these problems worse. Particles get stuck in valve spools or seats. Thick fluid or too much speed make smooth work harder.

Troubleshooting Tips for Noisy Hydraulic Pumps and Valves

Good troubleshooting begins with step-by-step checks to find the main cause.

Start by looking at filters and strainers for clogs or metal bits. Those bits show wear inside. Check suction pressure to make sure there is enough net positive suction head (NPSH) for what the pump needs.

Make sure fluid thickness fits the work conditions and heat levels. Low levels in the reservoir, loose intake lines, or worn couplings let air in. This makes noises louder.

Clean or change dirty fluid and parts. Set relief valve levels just right. Make sure pump speed matches what the system wants.

Regular care, such as checking fluid and looking at parts, cuts down noise problems. A plan to watch things closely catches changes soon.

Industry rules stress that too much noise often comes from wear, bad alignment, cavitation, aeration, or dirty fluid. Fixing these things makes equipment last longer and keeps efficiency high.

In summary, noises from hydraulic pumps and valves act as important alerts. Sharp whining shows cavitation or aeration. Metallic sounds uncover mechanical flaws. Chattering signals unsteady flow. Hissing points to relief valve troubles. Careful checks and steady care fix most problems before they cause big harm.

FAQ

What causes a high-pitched whining noise in hydraulic pumps?

Cavitation or aeration usually makes this sound. Cavitation creates vapor bubbles from low pressure drops. Aeration brings in air through leaks or low fluid levels.

How can metallic noises in a hydraulic pump be identified and fixed?

These noises often come from worn insides or couplings that are not aligned. Checking for junk in filters and doing alignment tests help find and solve the problem.

Why do relief valves chatter, and how is it resolved?

Dirt or wear stops proper closing. This causes quick cycling. Cleaning the valve, changing bad parts, or better fluid filtering fixes chattering.

What quick steps address hissing from hydraulic systems?

Look at relief valve settings and state. Change pressure levels or fix stuck valves to stop extra bypassing.

Is chattering near the pump inlet related to valves?

A leaking inlet check valve often causes this by letting fluid flow back. Changing or fixing the check valve brings back steady work.

Partner with a Reliable Hydraulic Manufacturer and Supplier

Equipment manufacturers, distributors, and system integrators need steady access to top-quality hydraulic components. This helps cut downtime and keep performance levels. POOCCA stands as a trusted manufacturer, supplier, and factory with over 20 years of expertise in producing gear pumps, piston pumps, vane pumps, motors, and valves. Offering more than 1,600 product variants, POOCCA delivers OEM-compatible solutions, custom designs, and rapid delivery from production facilities in China. Contact POOCCA today at sales@kamchau.com or +86 18927498997 to discuss bulk requirements, technical specifications, or partnership opportunities for reliable hydraulic supply chains.