Hydraulic motors work as key pieces in fluid power setups. They change the flow and pressure from a hydraulic pump into spinning mechanical power. This drives different kinds of machines in factories and on mobile equipment. Steady work in tough places comes from the exact teamwork of main parts like gears, vanes, pistons, and other linked pieces.

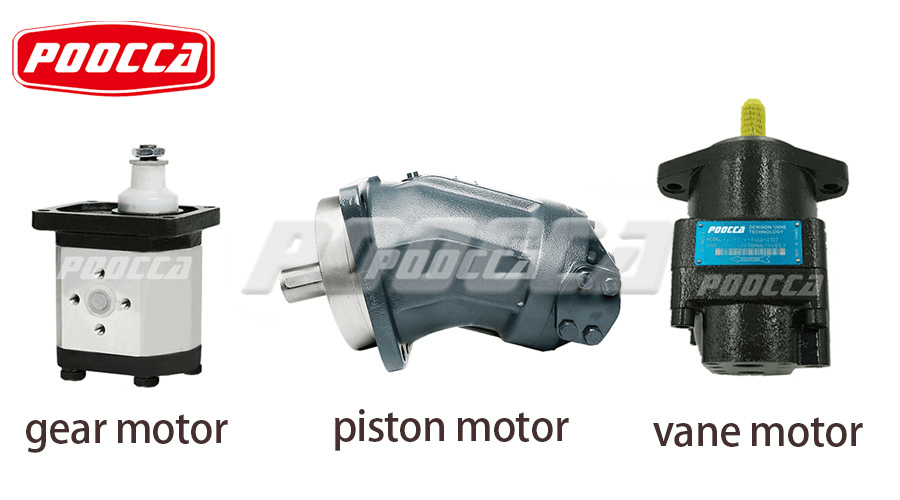

Hydraulic motors come in many designs. Each type needs its own inner parts for gear, vane, and piston styles. Knowing these differences matters a lot when matching a hydraulic motor to a pump. It helps get the best efficiency, long life, and power output.

Types of Hydraulic Motors

Other resources cover this topic in depth. They look at the most common designs. The main groups are gear, piston, and vane hydraulic motors. Gear motors have tough builds good for fast, nonstop spinning. They fit systems that need even output. Vane motors work well at slow speeds with high torque. This makes them right for things like injection molding machines and material handling gear. Piston motors come in axial and radial kinds. They give top power in a small space and run very well. People often use them in heavy industrial work and construction machines.

These groups split more into low-speed/high-torque (LSHT) and high-speed kinds. The choice depends on what the job needs, like torque amount, speed range, and working conditions.

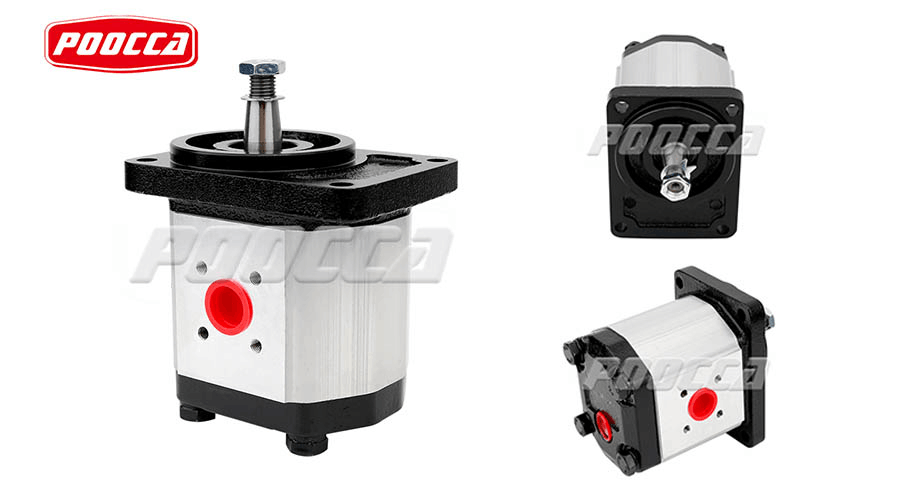

Gear Hydraulic Motor: Core Components

Gear hydraulic motors have a plain but strong design. It holds up well under medium to high pressures. Pressurized fluid comes in from the hydraulic pump. It hits the gears, makes torque, and sends spinning force through the output shaft.

- Driven Gear: This gear gets force straight from the incoming pressurized fluid. It spins and sends torque to the output shaft that connects to it. In this way, it turns hydraulic energy into mechanical spin.

- Idler Gear: It meshes with the driven gear. This helps move fluid and cuts backflow. But it does not link to the output shaft.

- Housing: It covers the gears and guides fluid flow. Careful making keeps internal leaks low. It stays strong under pressure and fights wear for a long time.

- Output Shaft: It carries torque to the load it drives. It needs good strength against fatigue and tight seals. This keeps the system solid and stops fluid from leaking out.

Vane Hydraulic Motor: Key Elements

Vane hydraulic motors run smooth and adjust well. They shine in jobs that need steady torque at slower speeds. Pressurized fluid from the pump pushes the rotor and sliding vanes. This makes growing chambers that create spinning motion.

- Rotor: It attaches to the drive shaft. Fluid pressure makes it spin while it pushes the vanes out.

- Vanes: These sit in slots on the rotor. They slide out from pressure or spinning force. This keeps them touching the housing wall to form tight chambers for good torque.

- Housing: It has an off-center hole to make chamber sizes change. Smooth inside walls cut friction and leaks.

- Ports: Inlet ports bring in high-pressure fluid. Outlet ports let low-pressure fluid go out. Good port shapes lower noise, raise energy use, and keep balance.

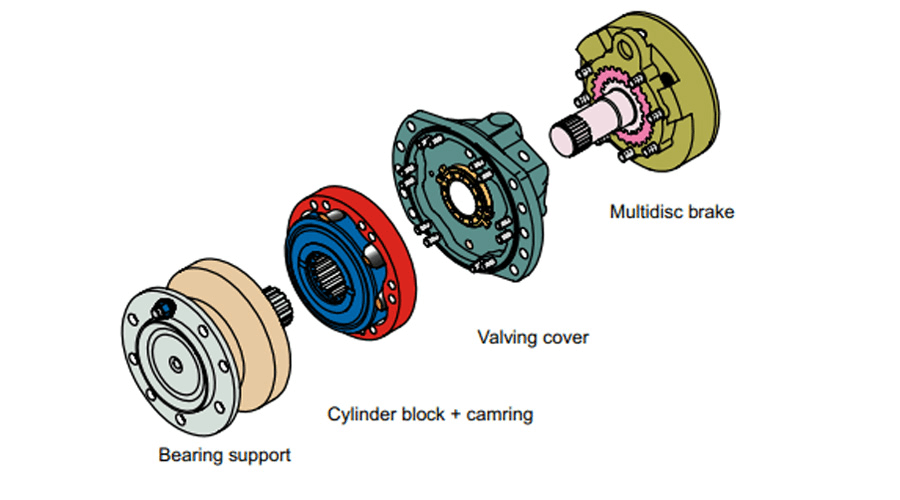

Piston Hydraulic Motor: Internal Mechanism

Piston hydraulic motors do best in high-pressure, high-efficiency cases. They come in axial and radial builds for heavy jobs. These motors handle big loads with care.

- Cylinder Block: It holds the pistons and lets them move back and forth. Strong materials and close fits reduce wear and inner leaks.

- Pistons: They move in and out from fluid pressure. This changes hydraulic energy to mechanical force. Fine work and hard surfaces give long life.

- Swashplate / Bent-Axis Mechanism: Axial piston motors use this part. It turns straight piston motion into spinning output. It also allows changes in displacement.

- Stator: Radial piston designs use this. It gives a steady surface for pistons to push against. This makes even torque.

- Valve Plate: It sends high-pressure fluid to piston areas and guides used fluid out. This supports steady, efficient cycles.

Glossary: Hydraulic Motor & Pump Terminology

Common words in hydraulic motor and pump systems include:

- Bore: Inside diameter of the cylinder for the piston. It affects pressure strength directly.

- Compensator: Part in pumps that changes flow to stop too much pressure in the motor setup.

- Flange: Mounting part made for tight, no-leak links and to fight shakes.

- Housing: Outer cover built for high strength and to keep parts lined up.

- Inlet / Outlet Valves: They control fluid in and out. This boosts efficiency and stops reverse flow.

- Seals: Parts like O-rings that stop leaks where surfaces meet.

- Shafts: They carry torque from inside parts to outside loads.

- Swashplate: Slanted disc in axial piston setups. It changes piston back-and-forth into rotation.

Knowing these parts and what they do helps pick the right hydraulic motor—gear, vane, piston, or orbital—for better system life, work, and safety.

Frequently Asked Questions (FAQ)

Which type of hydraulic motor suits high-torque, low-speed applications?

Piston motors, particularly radial and certain axial designs, along with orbital motors, provide excellent high-torque performance at low speeds.

How does a gear hydraulic motor differ from a vane motor?

Gear motors offer ruggedness and high-speed capability with simpler construction, while vane motors deliver smoother operation, higher starting torque, and suitability for low-speed scenarios.

What factors determine the choice between axial and radial piston motors?

Axial piston motors provide variable displacement and high efficiency in compact designs, whereas radial piston motors offer superior torque density for heavy-duty, low-speed tasks.

Can hydraulic motors operate in both directions?

Many designs, including gear, vane, and piston types, support bidirectional rotation by reversing fluid flow direction.

Contact POOCCA Hydraulic Manufacturer and Supplier for Premium Hydraulic Motors

POOCCA stands as a leading manufacturer, supplier, and factory specializing in high-quality hydraulic motors, including gear, vane, piston, and orbital types from trusted series such as Danfoss, Rexroth, Parker, Eaton, and more. With over 20 years of experience, a comprehensive range exceeding 1,600 products, rigorous quality testing, and global exports to more than 120 countries, POOCCA delivers factory-direct solutions tailored for industrial, construction, agricultural, and mining applications.

Reach out today for competitive pricing, customization options, technical support, and reliable delivery. Contact the team via email at sales@kamchau.com or phone at +86 18927498997 to discuss requirements and secure optimal hydraulic motor solutions.