How Does a Gear Pump Work?

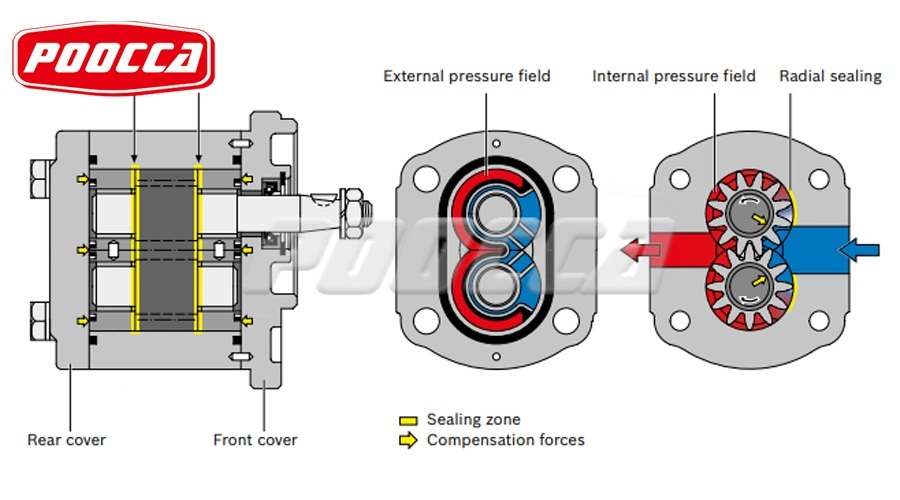

Gear pumps are one of the most common types of positive displacement pump. They operate by an unchanging volume of fluid passing between the teeth of two meshing gears and their casing at a constant rate (not between the gears themselves). As the gears rotate and the meshed teeth separate, a partial vacuum is formed that fills with fluid. As the gears continue to rotate, they trap the liquid and move it around the casing from the suction to the discharge point. This mechanism ensures a steady flow, making gear pumps particularly effective for transferring viscous fluids in hydraulic systems.

Types of Gear Pumps

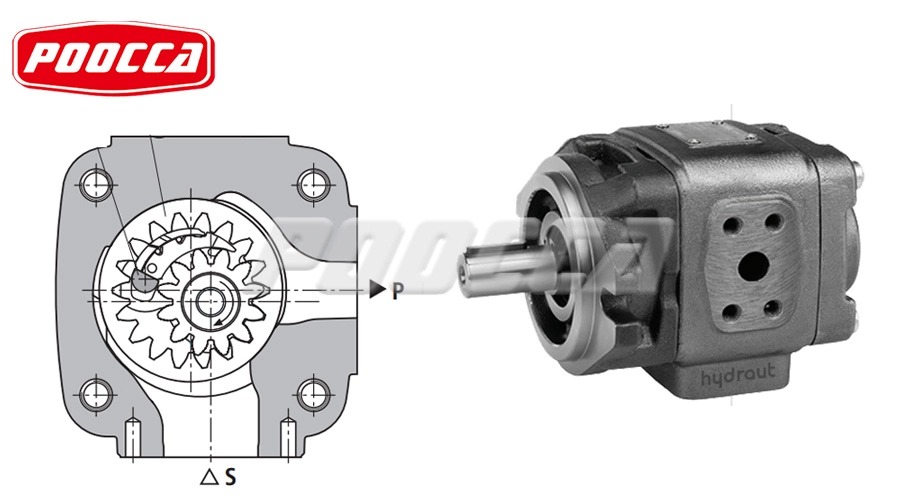

External Gear Pump

External gear pumps feature two identical gears positioned side by side, rotating into one another. One gear is driven by the motor and in turn moves the other gear. These pumps are known for their compact construction and cost-efficiency. They work to higher pressures and are suitable for medium/low temperature fluids. Additionally, when equipped with spur gears, they can be bi-directional.

Internal Gear Pump

Internal gear pumps operate on a “gear within a gear” principle, whereby one gear (the idler) is positioned inside another gear (the rotor). They work to moderate pressures but are capable of handling high temperature fluids. These pumps are often supplied with a heating jacket to maintain fluid temperature. They are always bi-directional and provide smooth, pulse-less flow ideal for precise applications.

Design Benefits

High Pressures

High viscosity fluids are able to be pumped over long distances using external gear pumps, thanks to their ability to handle high pressure applications.

Self-Priming Capabilities

Gear pumps benefit from excelling self-priming capabilities thanks to their rotating gears evacuating any air in the suction line, and forcing the liquid into the pump inlet.

Bi-Directional

Internal gear pumps have spur gears, which enable flow in either direction. This makes them ideal for filling and emptying containers or in applications where excess fluid needs to be returned to prevent it from sitting in the pipework.

Steady and Pulse-less Flow

Both types, but in particular internal gear pumps, provide a smooth, constant flow as their gears roll in the same direction without interrupting the liquid flow. The tight internal clearances between the gear teeth and the pump casing allow very precise volumes of fluid to pass for each gear revolution.

Typical Applications of a Gear Pump

Gear pumps are one of the most common pump types for the handling of clean oil and other self-lubricating, high viscosity liquids such as paints and soaps in relatively high pressure installations. Applications that gear pumps are commonly used within include:

- Automotive, lube and fuel oils

- Hydraulic applications

- Paint and ink

- Resins, adhesives and polymers

- Pulp, lime and lye

- Small scale hot oil circulation

- Liquid soap

However, they should only be used with clean, non-abrasive fluids since solids can damage internal components.

Operation Guidance

Do Not Run Dry

If a gear pump is run dry, the unlubricated gears will rub together causing friction. The heat caused by this friction will cause the gears to expand and begin wearing against the pump casing resulting in damage to the internals.

Operate at Maximum Speed

Gear pumps struggle to maintain performance at low speeds and flow rates due to their weak volumetric efficiency. Therefore to get the best from their output they need to be operated as close to their maximum rated speeds as they can.

Inspect Bearings

Each gear is supported by a shaft which has bearings on either side of the gear; an external gear pump has four bearings and an internal gear pump has two. These need to be regularly checked for wear as they are what maintain the balance of the gears.

Check Gear Clearance

The operation of a gear pump relies on the tight clearances between the teeth and the chamber. A common test to see if there has been wearing is to try and put a piece of paper between the clearances; if it easily passes there is evidence to suspect wear.

Source High Quality Gear Pumps from POCCA

POOCCA Hydraulic (Shenzhen) Co., Ltd. was established in 2006 and has four companies in Hong Kong, Guangdong, Jiangsu and Zhejiang. We are a comprehensive hydraulic service company specializing in the research and development, manufacturing, maintenance and sales of hydraulic pumps, motors, valves and related parts.

POOCCA offers premium internal and external gear pump solutions tailored for demanding industrial environments. Their product lineup includes models like:

- Ronzio Z3 Series: High-performance cast iron cover with aluminum alloy body.

- CBK Series Hydraulic Gear Pump: Compact design offering up to 85.5 MPa pressure.

- POOCCA SGP2 Series: External forklift pump featuring DU bearings with high-strength aluminum accessories.

With our well-equipped facility and highly skilled workforce, we are well-equipped to cater to the needs of various industries and provide tailor-made hydraulic solutions to our valued clients.

POOCCA’s commitment extends beyond manufacturing. They offer pre-sales consultation, post-sales support including warranty services, repairs, feedback mechanisms as well as customized packaging solutions.

FAQ

What are the advantages of an external gear pump?

External gear pumps provide high pressure, are suitable for medium to high-viscosity fluids, have self-priming capabilities, and can handle large outlet sizes with high capacities. They are also available in bi-directional flow designs.

What are the benefits of an internal gear pump?

Internal gear pumps offer smooth, pulse-free flow, are bi-directional, and can handle high-temperature fluids. They are also ideal for applications requiring precise fluid metering.

Can internal gear pumps handle high temperatures?

Yes, internal gear pumps are capable of handling high-temperature fluids and are often supplied with a heating jacket to maintain the fluid temperature.

Can gear pumps handle low viscosity fluids?

Generally, gear pumps, especially internal gear pumps, are not suited for low viscosity fluids as they can cause “slip” in the pump, leading to reduced flow and efficiency.

How should gear pumps be operated?

Gear pumps should not be run dry, as unlubricated gears can cause friction and damage. They should also be operated close to their maximum rated speeds to ensure optimal performance.

Are gear pumps suitable for pumping abrasive fluids?

External gear pumps, especially those with high-quality materials, can handle abrasive fluids effectively. However, gear pumps are not ideal for fluids with large solid particles, as they can cause damage to the pump.