The need for strong and dependable hydraulic systems is growing fast in many different fields. These systems are super important, whether they’re running big construction machines, factory tools, or helping with mining and nature care projects. They’re like the heart of today’s big building and work plans. Right at the center of it all are hydraulic piston pumps. These turn machine power into liquid power really well. Out of these, variable displacement and axial piston pumps are special because they work great, adjust easily, and save energy in tough jobs.

How Hydraulic Piston Pumps Work

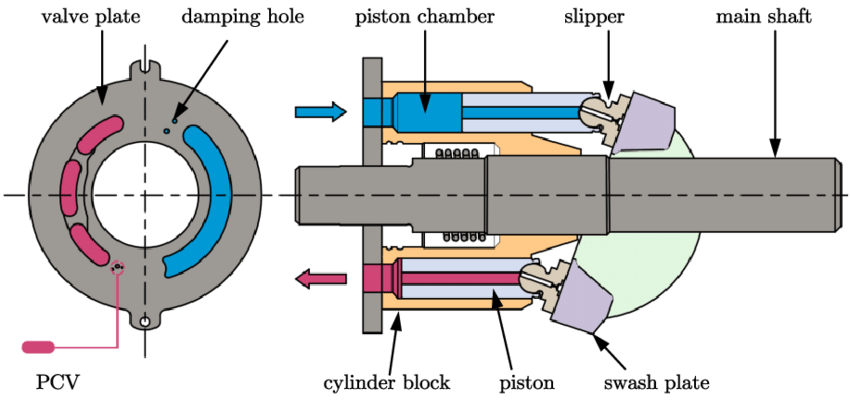

Hydraulic piston pumps are key parts in today’s hydraulic setups. They make strong liquid flow to run machines and tools. The main idea is simple: they change machine energy into liquid energy. A spinning piece, like a swashplate or cam, pushes pistons inside a cylinder block. When the pistons move back and forth, they pull in liquid during one step and push it out with lots of force in the next step.

This high-pressure liquid then goes to parts that do the actual work, like motors. What makes these pumps cool is their ability to handle super high pressure, often more than 6,000 PSI. Plus, they’re small, don’t make much noise, and work really well. That’s why they’re perfect for tough, high-power tasks.

The Significance of Variable Displacement Piston Pumps

A variable displacement piston pump is a big deal in modern hydraulic systems. It lets you control the flow and pressure just right for the job. Unlike pumps that always give the same amount of liquid, these can change how much they put out as needed.

They do this with things like movable swash plates that adjust how far the pistons move. Here’s why they’re awesome:

- Changeable Flow: You can tweak the pump to match what the system needs. This makes them great for changing conditions.

- Fast Reaction: They quickly adjust to different loads, keeping everything running smooth and steady.

- Power Saving: When less is needed, they cut back on output. This lowers energy use and saves money on running costs.

Also, managing the flow better means less stress on parts. So, things last longer and don’t need fixing as often.

Spotlight on Axial Piston Pumps

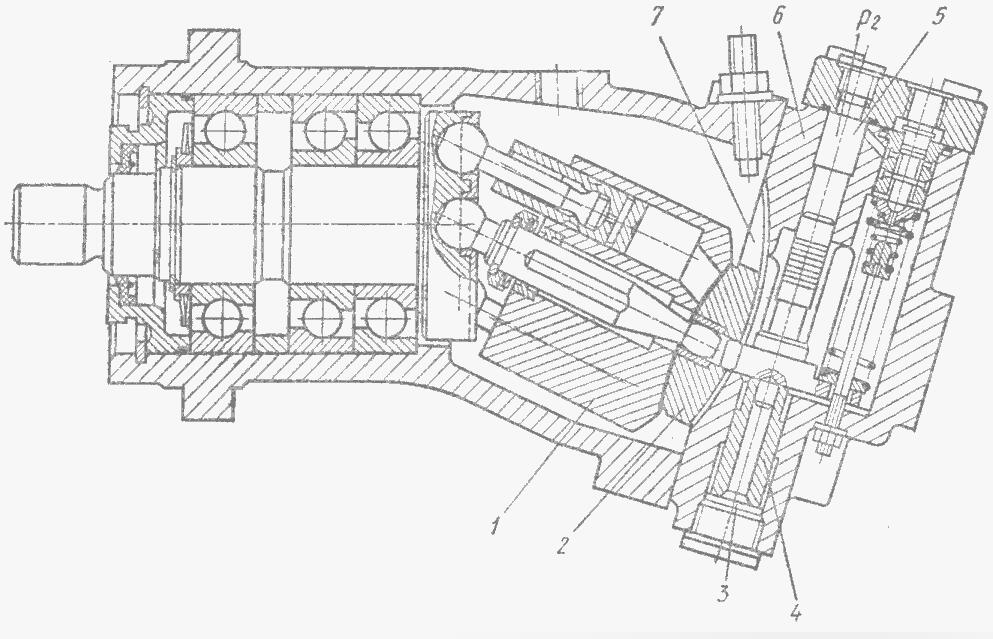

Hydraulic axial piston pumps are built for top performance in hard settings. In these pumps, pistons line up straight with the drive shaft. This setup helps move liquid smoothly and control flow really well.

Design and Mechanics

An axial piston pump is a smart piece of gear made for high-pressure, heavy-duty systems. It uses a swash plate or bent-axis style to guide piston movement. This lets the pump change its output, which is super handy for active systems.

These pumps are made from tough stuff like hard steel or strong mixes to handle huge pressure and rough wear. Their small shape makes them easy to fit into tight spots, like in moving machines.

Applications

Axial piston pumps are used a lot in:

- Construction: They power big tools like excavators, loaders, and cranes.

- Mining: They run drills, movers, and systems that carry ore.

- Marine Operations: They’re key in sea work where steady hydraulic power is a must.

Since they can fine-tune the flow, they’re great for jobs where the load keeps changing.

Hydraulic Piston Pump Manufacturers: What Sets the Best Apart?

When picking a maker for hydraulic axial piston pumps or other types, think about these things:

Here are some big points to check:

- Strong Materials: Pumps built with tough stuff like high-chrome mixes last longer and work better.

- New Ideas: Companies that put money into research make pumps with cool, modern features.

- Made-to-Order: Being able to shape pumps for specific needs helps them fit and work great.

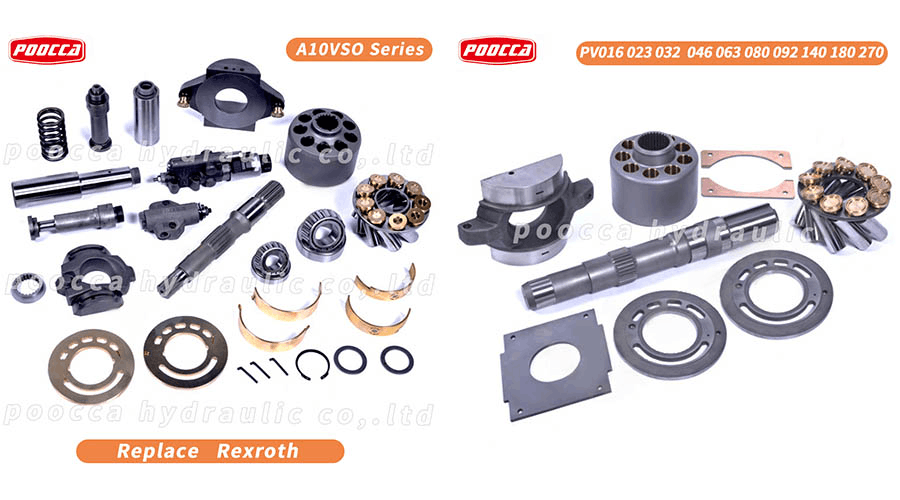

POOCCA stands out as a top name among piston pump makers. They offer solid options for many fields, add smart tools for spotting issues early, and give great help to customers.

Applications of Hydraulic Piston Pumps Across Industries

The flexibility and strength of hydraulic piston pumps make them super useful in tons of areas.

Industrial Manufacturing

They power things like big presses, molding tools, and robot systems. They give the exact control needed for stuff like robotic arms or building lines.

Construction

Variable displacement piston pumps are a must for gear like cranes and excavators. Their ability to adjust keeps things running well even when the work changes a lot.

Marine Dredging & Mining

In sea dredging, they keep pressure and flow steady. In mining, they help drills and ore movers handle rough, tough places.

Environmental Management

Used in trash compactors or balers, hydraulic piston pumps make these machines work better. They help pack things tight, save space, and support green efforts.

Future Trends in Hydraulic Piston Pump Technology

Hydraulic tech keeps getting better with smarter ideas:

Energy Efficiency & Sustainability

As more fields care about being green, pumps are using stuff that can be reused and better flow tricks to save power.

IoT Integration

Pumps with IoT can change hydraulic systems. They let you watch things as they happen and fix stuff before it breaks.

Innovations in Design

Look for stronger but smaller axial designs soon. Future changes will aim for bigger pressure limits and tougher builds with coatings that fight wear.

FAQ

Q1: What distinguishes an axial from a radial piston pump?

A1: Radial piston pumps have pistons sticking out sideways from the shaft, making them bigger and less smooth. Axial designs line up pistons straight with the shaft for better work.

Q2: Why choose variable over fixed displacement?

A2: Variable displacement tech is key for better results. It only gives what’s needed, saving energy and effort.

Q3: Are these suitable for mobile equipment?

A3: Yes. Their small size and adjustable flow make them perfect for moving gear in building or farm work.

Source High-Quality Hydraulic Piston Pumps from POOCCA

For companies looking for trusty, strong, and top-notch hydraulic piston pumps, POOCCA Hydraulics has it all. With over 20 years of industry experience, POOCCA is great at making and selling gear pumps, piston pumps, vane pumps, hydraulic motors, valves, and accessories. Their items are used in construction, mining, agriculture, marine, and factory jobs, with yearly sales over USD 16 million to more than 75 countries.

POOCCA’s piston pumps, including variable displacement and axial designs, are built for high efficiency, long life, and exact flow control. They also offer customization, helpful support, and quick shipping from their spots in Shenzhen, Guangdong, Jiangsu, and Zhejiang. This keeps your hydraulic systems running great.

Contact POOCCA Today to get your hydraulic piston pumps:

📞 +86 18927498997

✉️ sales@kamchau.com