The need for strong and dependable hydraulic systems keeps growing in many industries around the world. These systems power big construction machines, help with mining work, run accurate tasks in marine settings, and support factory operations. Hydraulic piston pumps act as main parts in these setups. They turn mechanical power into fluid power well, show great strength, handle high pressure, and fit different needs.

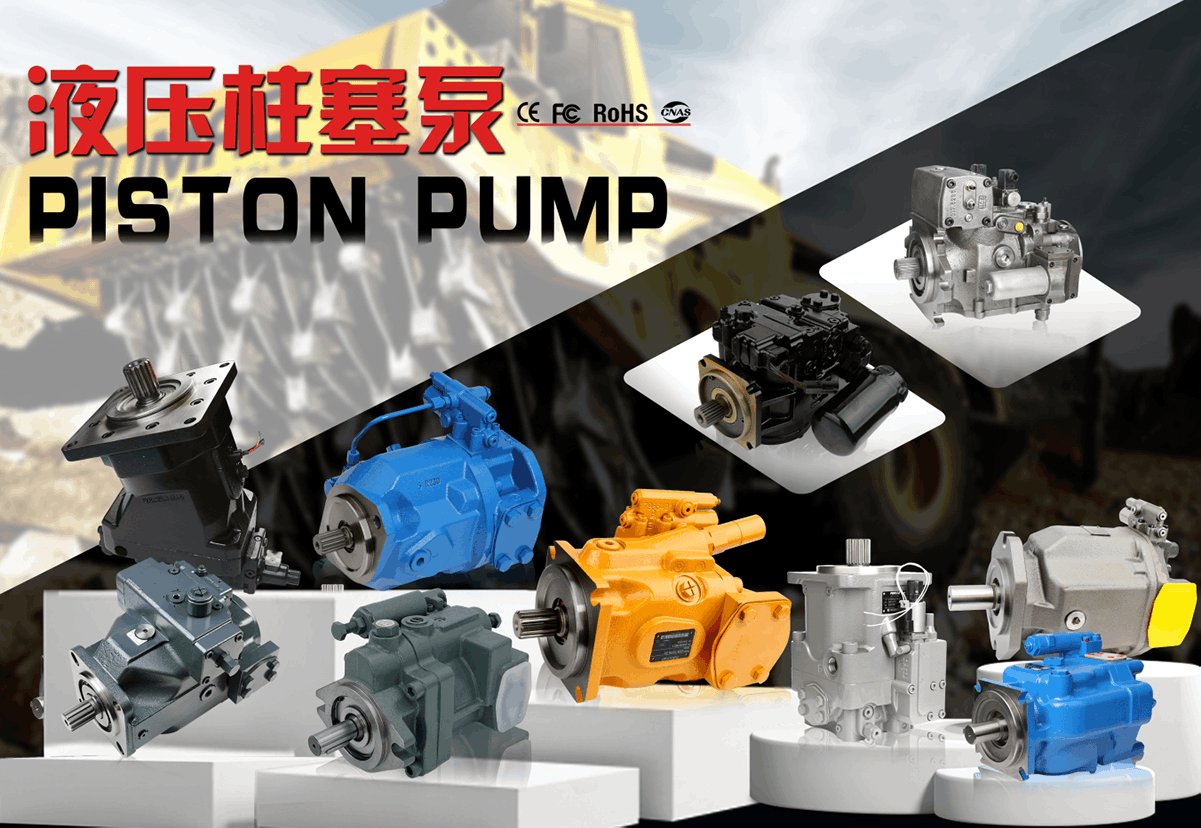

New developments in variable displacement piston pumps and axial piston pumps solve problems like saving energy and getting exact control. These types give changeable flow amounts, use less power, and work better when conditions change fast. Top makers create good quality versions that match well-known names like Rexroth, Parker, Vickers/Eaton, Yuken, Nachi, and Danfoss. This gives solid choices for tough jobs.

Hydraulic piston pumps stay very important for keeping work smooth and reliable in today’s machines. This piece looks at how they work, main kinds, and wide uses. It also points out new ideas that make them perform better and help the environment more.

How Hydraulic Piston Pumps Work

Hydraulic piston pumps create strong fluid flow to run machines in areas like building sites, mines, and automated factories. Power comes from electric motors, engines, or other hydraulic sources. It drives the shaft and changes energy in a clear way. This setup works well even in hard places.

Closed-circuit setups offer better control and save more energy to fit exact needs.

Basic Operation of Hydraulic Piston Pumps

The main part changes mechanical input to hydraulic output. It uses a turning swashplate, cam, or bent-axis setup to move pistons inside a cylinder block. The back-and-forth piston action makes suction and push cycles. Fluid comes in through the inlet during suction. Then it leaves under pressure during discharge.

Inlet and discharge ports control flow with a port plate or valve plate. This directs the fluid. High-pressure fluid then drives actuators, motors, and other parts. It gives smooth and steady work under different loads.

Key features of hydraulic piston pumps include:

- High-Pressure Tolerance: They handle over 6,000 PSI. This fits heavy tasks in construction and mining.

- Efficiency: Less inner leaks and better flow give steady results.

- Compact Design: They pack a lot of power in a small space. This helps where room is tight.

- Low Noise: They run quieter in factory areas.

Axial Piston Pumps vs. Other Pump Types

Axial piston pumps stand out among hydraulic piston pumps. Their pistons line up parallel to the drive shaft. This gives good and exact flow. As positive displacement pumps, they keep steady volume even when pressure changes.

Compared to others: Radial piston pumps have pistons at right angles to the shaft. They work well at low speeds with high torque. But they take more space and adjust less for changing flow. Gear pumps stay simple and cheap for steady jobs. Yet they fall short on high pressure and variable flow. Vane pumps handle medium pressure well. Still, they do not last as long or reach high pressure like axial ones.

Advantages of Axial Piston Pumps

Axial piston pumps bring:

- Efficiency: The straight setup cuts energy loss.

- Durability: Strong materials stand up to rough use and high pressure.

- Adaptability: Many have variable displacement. This matches flow to changing needs.

These points make axial piston pumps a top pick for strong hydraulic systems.

The Significance of Variable Displacement Piston Pumps

Definition and Key Features

Variable displacement piston pumps change output flow and pressure to fit what the job needs. Fixed displacement ones always give the same amount. But these adjust by changing the swashplate angle. That shortens or lengthens piston stroke and moves less or more fluid each cycle.

Key features include:

- Adjustable Displacement: Flow changes to match needs. This adds flexibility.

- Dynamic Performance: They react fast to load shifts. This keeps things stable.

- Energy Savings: Less output at low demand cuts power use and costs.

These traits make variable displacement piston pumps key for systems that need accuracy and low waste.

Enhancing System Performance with Variable Displacement Technology

Variable displacement boosts how well hydraulic systems run. It makes real-time changes.

Improved Efficiency Flow matches what is needed. No extra fluid gets pushed. This lowers waste and power use.

Reduced Heat Generation Less useless flow stops parts and fluid from getting too hot.

Extended Component Life Careful running cuts wear on valves, actuators, and seals.

Advantages Over Fixed Displacement Pumps

Fixed displacement works fine for steady loads. But it wastes energy through relief valves when loads change. Variable ones supply just enough fluid. They save energy, give better control, and fit mobile gear, factories, and sea work.

Spotlight on Axial Piston Pumps

Design and Mechanics of Axial Piston Pumps

Axial piston pumps fit high-pressure and high-work systems. Pistons sit parallel to the drive shaft in a cylinder block. Rotation from a swashplate or bent-axis makes pistons move back and forth. Stroke length changes with angle to control flow.

Key elements:

- Swash Plate or Bent-Axis Mechanism: This allows variable displacement.

- Robust Materials: Hardened steel and alloys fight high pressure.

- Compact Housing: Easy to fit where space is small.

Applications in Heavy-Duty Industries

Axial piston pumps support:

- Construction: Excavators, loaders, and cranes get steady power.

- Mining: Drills, conveyors, and haulers run in rough spots.

- Marine Operations: Dredging, steering, and winches stay reliable.

Performance Benefits in Variable Flow Requirements

- Smooth Operation: Steady flow cuts shakes.

- Quick Responsiveness: Adjusts fast to new demands.

- Enhanced Safety: Exact control avoids overloads.

Hydraulic Piston Pump Manufacturers: What Sets the Best Apart?

Factors to Consider When Evaluating Piston Pump Manufacturers

Choosing involves:

- Material Quality: Strong alloys for long life.

- Technological Innovation: R&D adds smart features.

- Customization: Special fits for matching other parts.

- Customer Support: Good help after sale.

The Role of Innovation in Meeting Industry Challenges

Top makers work on lower energy use, smaller sizes, and checks before failure. This meets real work needs.

Why POOCCA Stands Out

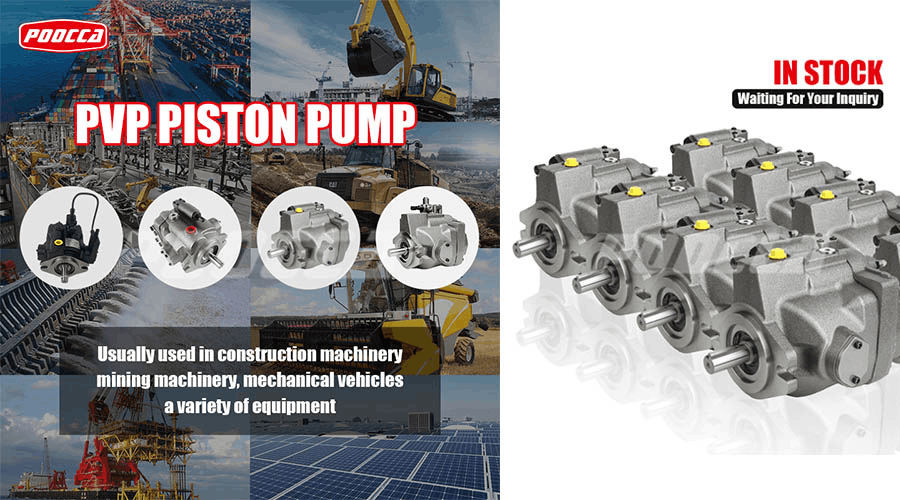

POOCCA excels as a hydraulic piston pump manufacturer and supplier. It offers advanced variable displacement and axial designs. These match big names like Rexroth A10VSO/A4VSO, Parker PV/PVP, Vickers PVH, Yuken A/AR, and more. POOCCA gives high-efficiency, strong OEM-quality replacements. It also provides customization and strict testing with a 99.9% qualification rate. This brings reliable work for industries everywhere.

Applications of Hydraulic Piston Pumps Across Industries

Hydraulic piston pumps deliver high pressure and exact flow for many fields.

Industrial Manufacturing and Assembly Power presses, molding machines, and automation lines run with energy-saving control. This keeps output steady.

Construction and Infrastructure Development Excavators, cranes, and concrete gear get adaptive flow for hard jobs.

Marine Dredging and Mining Operations Axial types handle sand removal, drilling, and moving in rough settings.

Environmental and Waste Management Compactors and balers process materials well. This supports green goals.

Common Challenges and Solutions in Hydraulic Piston Pumps

Cavitation: Stop it with good priming and right fluid levels. Seal Leakage: Check and change seals often.

Maintenance Tips to Prolong Pump Life

Do regular checks, keep fluid clean, and follow service times. This helps pumps last longer.

Future Trends in Hydraulic Piston Pump Technology

Focus on Energy Efficiency and Sustainability

Green materials and better designs cut power use.

Integration with IoT and Smart Hydraulic Systems

Real-time checks, failure prediction, and remote changes improve work.

Innovations in Axial and Variable Displacement Designs

Higher pressures, smaller builds, and new coatings extend use and life.

Conclusion

Hydraulic piston pumps give steady work in tough spots. Variable displacement and axial designs bring flexibility, low energy use, and green benefits. POOCCA, as a leading hydraulic piston pump manufacturer and supplier in China with over 20 years of experience, offers high-quality, customizable solutions compatible with top brands. It supports industries worldwide with durable, cost-effective products.

Contact POOCCA for Hydraulic Piston Pump Solutions

POOCCA , as a professional manufacturer and supplier of hydraulic piston pumps, offers variable displacement axial piston pumps, OEM equivalents, and customized solutions for industrial, mobile, and heavy-duty applications. With extensive product ranges including Rexroth, Parker, Vickers, and Yuken compatible series, POOCCA provides reliable, high-efficiency options at competitive prices.

Contact the factory directly for quotes, technical specifications, or tailored requirements. Reach out via email at sales@kamchau.com or phone/WhatsApp at +86 18927498997 to discuss piston pump needs and receive expert support from the POOCCA team.