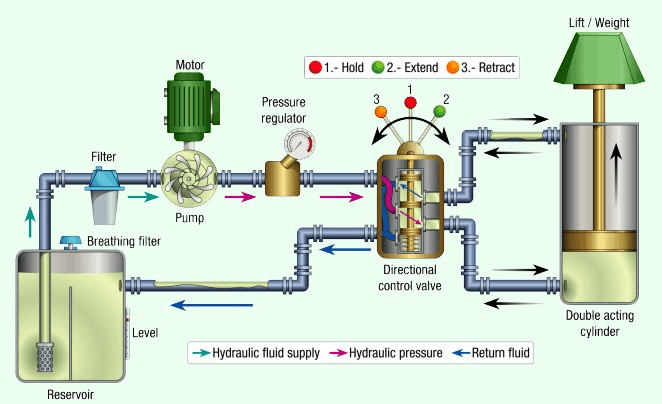

Hydraulic systems rely on fluid to transfer energy and create mechanical power. POOCCA provides a full line of vane pumps, gear pumps, and piston pumps. The company also offers gear motors, piston motors, vane motors, orbital motors, and flexible hydraulic hoses needed to move fluid around the system.

Even with strong quality, long life, and solid performance from these parts, low temperatures can still cause trouble for hydraulic systems. This piece looks at how cold weather changes hydraulic fluid and the whole system’s work. It also shares useful ways to cut down on possible issues.

Hydraulic Fluid Freezing Point

Hydraulic fluid usually needs much colder conditions than water’s freezing mark before big problems show up in parts. The real limit changes based on things like height above sea level and the work setting. Most often, hydraulic fluid turns solid near -10°F (-23°C).

Once hydraulic fluid hits that cold level, it hardens and stops all flow. It becomes useless and blocks everything. Even when it’s a bit warmer than that point, low heat makes the fluid much thicker. Higher thickness slows movement through pipes and parts. This cuts efficiency and makes pumps and motors respond slowly. As a result, machines act sluggish and parts wear out faster.

Rubber pieces in hoses and other spots also suffer in low heat. Rubber gets stiff near its glass change point, often close to -40°F (-40°C). This depends on the mix and firmness. In very cold air, rubber can get hard and break easily. It cracks or splits. Hydraulic hoses, seals, supports, and connectors face the biggest risk. They can leak and hurt the system’s strength.

Effects on Hydraulic Systems Across Industries

Hydraulic systems matter a lot in many fields. Cold weather hits machines hard in transport, farming, and building work. Here is what happens in each area:

- Transport: Hydraulic setups in trucks handle lifts, brakes, and steering. Low temperatures thicken oil and stiffen seals. This leads to slow actions, weaker braking, and trouble with lift parts.

- Agriculture Equipment: Tractors, harvesters, and loaders count on hydraulic power for quick work. Cold slows things down, puts extra stress on pieces, and raises the chance of breakdowns during key planting or harvest times.

- Construction Equipment: Excavators, bulldozers, and cranes use hydraulic force a great deal. In cold weather, systems show delays in response, use more energy, and face higher risks of hose or seal breaks. This causes stops in projects and costly lost time.

Tips for Maintaining Hydraulic Systems in Cold Weather

Cold weather always comes, but smart steps can guard hydraulic systems well. These actions help keep things reliable through winter:

- Check and Monitor System Fluids Do regular looks at hydraulic fluid with dipsticks or similar tools. Make sure levels stay right and flow works fine. Fluid needs to sit in suggested temperature ranges and move easily. If thick fluid won’t drip, it means too much cold. Warm it first before running. Also keep fluid clean and without water mixed in.

- Inspect and Test Components Before Operation Look over hoses, seals, pumps, and motors before starting. Spot any harm like splits, rips, or drips. Rubber items show more weakness in cold. Keep extra hoses, seals, and fittings ready. This cuts wait time for fixes.

- Warm Up the System Let the system heat slowly before heavy use. Run the engine at lower speed or move attachments for 10-15 seconds. This pushes fluid around and warms it. It stops sudden pressure jumps that hurt parts. In strong cold, pair low-temperature hydraulic fluids with heaters or warm pads. They hold good temps when the machine sits still.

- Use Hydraulic Fluid for Cold Weather Pick special low-temperature hydraulic fluids. They stay thinner in cold spots. This gives smoother flow and less push on parts. Talk with suppliers to choose the best cold-weather fluid for your needs. It helps performance in tough setups.

- Store Equipment Properly Keep machines in places with controlled heat. This stops fluid from getting too thick and rubber from breaking down. If no indoor spot exists, use covers or engine blankets to hold warmth.

- Install Protective Covers Put on covers that resist weather. They guard hoses and connectors from wind, ice, and snow. Less exposure means less harm.

- Perform Regular Maintenance Set up planned service during winter. Swap out worn pieces fast and keep systems free of dirt. Steady care stops small troubles from growing big.

Preparing for Cold Weather: The Key to Reliability

Cold weather brings steady tests to hydraulic systems. Fluid can harden if it gets cold enough. Good prep and steady upkeep give steady work in all fields. Taking these steps ahead lowers freeze risks. It cuts costs and keeps operations smooth over time.

Order POOCCA Hydraulic Products and Service Today

POOCCA keeps a wide stock of new hydraulic motors, pumps, valves and hoses built for strong work in hard settings, even cold ones. The company gives expert repair, upkeep, and engineering help to hold system performance high. The team guides makers, suppliers, and plants in picking the right parts and fluids for exact jobs. This ensures top reliability in rough weather. Reach POOCCA at +86 18927498997 or sales@kamchau.com to talk about ways to protect hydraulic systems in cold conditions.

FAQs

What temperature causes hydraulic fluid to freeze?

Hydraulic fluid generally solidifies around -10°F (-23°C). This changes with the type and setting. Hardening stops flow fully.

How does cold weather increase hydraulic fluid viscosity?

Lower heat makes fluid thicker. It slows flow and drops pump and motor work. This brings slow actions and more wear.

Which hydraulic components are most affected by cold?

Rubber hoses, seals, and fittings turn brittle near -40°F (-40°C). They risk cracks, leaks, and breaks.

Why warm up hydraulic systems in cold weather?

Warming stops quick pressure shifts and part damage from thick fluid. It gives smoother starts and longer life.

What are the benefits of low-temperature hydraulic fluids?

These fluids keep lower thickness in cold. They allow better flow, less stress, and quicker system response.

How often should hydraulic systems be inspected in winter?

Do regular checks before use and planned service. This spots problems early, mostly for rubber parts weak to cold harm.