Pumps act as the main part of hydraulic systems. They change mechanical energy into fluid power to run machines and tools. This key role brings up many questions from people in the industry about choosing, running, caring for, and fixing problems with pumps.

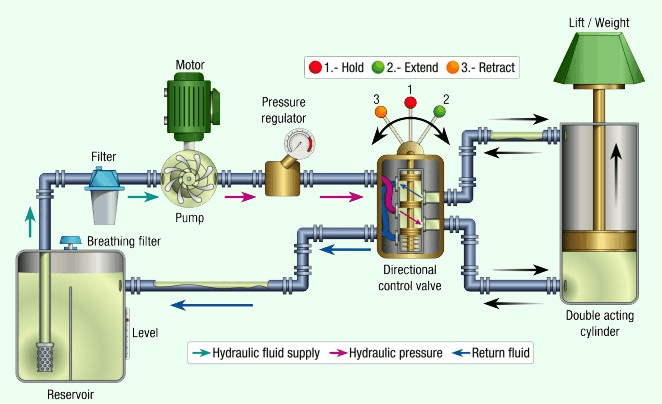

Hydraulic pumps work by turning mechanical input—usually from an electric motor or engine—into hydraulic energy. This energy drives actuators like cylinders and motors in the system.

Hydraulic pumps make this change happen in two main steps.

- They create a vacuum at the inlet. This lets atmospheric pressure push fluid from the reservoir into the pump.

- They push the fluid out through the outlet at higher pressure into the hydraulic circuit.

The whole hydraulic system depends on this steady energy transfer to work at its best.

Frequently Asked Questions About Hydraulic Pumps

Q: Which Type of Pump Should Be Used?

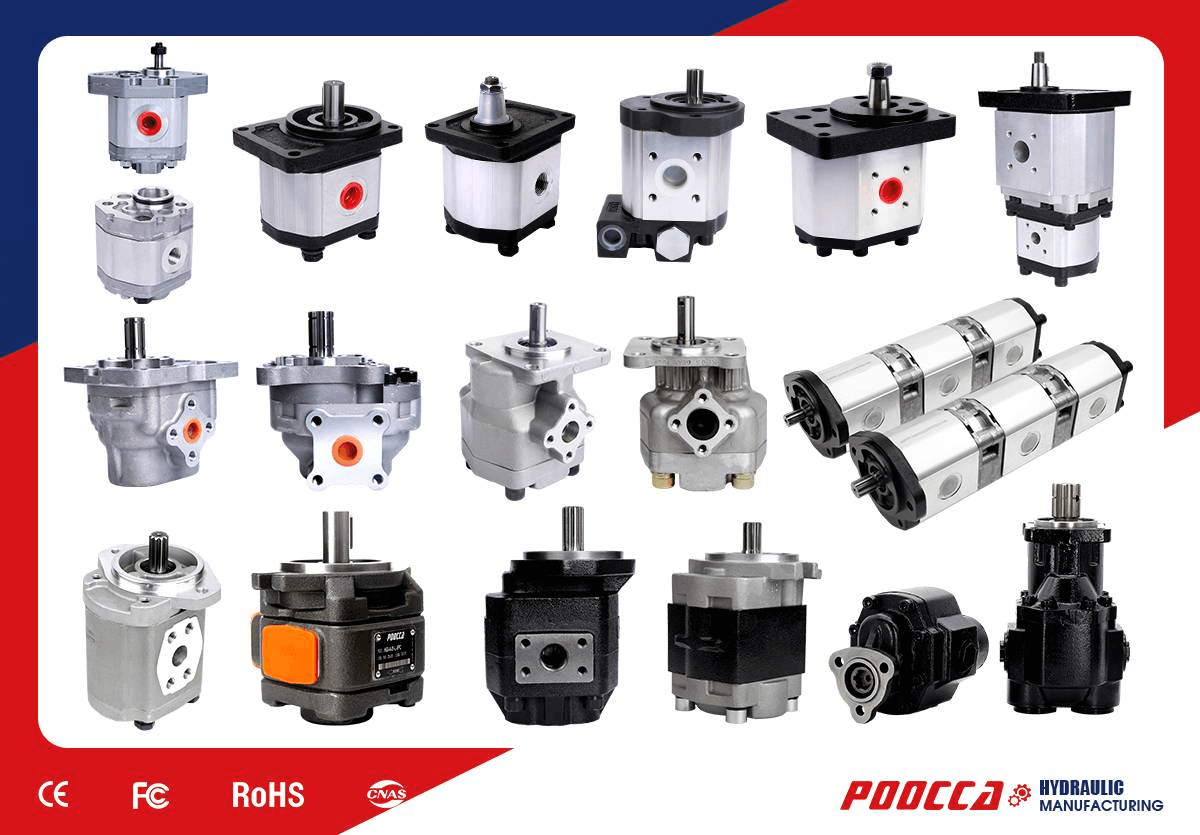

A: Choosing a hydraulic pump depends on what the job needs. This includes pressure, flow, efficiency, noise amount, and cost factors. Three main kinds stand out in hydraulic systems.

- Gear pumps give low-cost, trustworthy, and long-lasting results with easy setup. They do well in many normal tasks. However, they lose some efficiency after long use. They also make more noise while running.

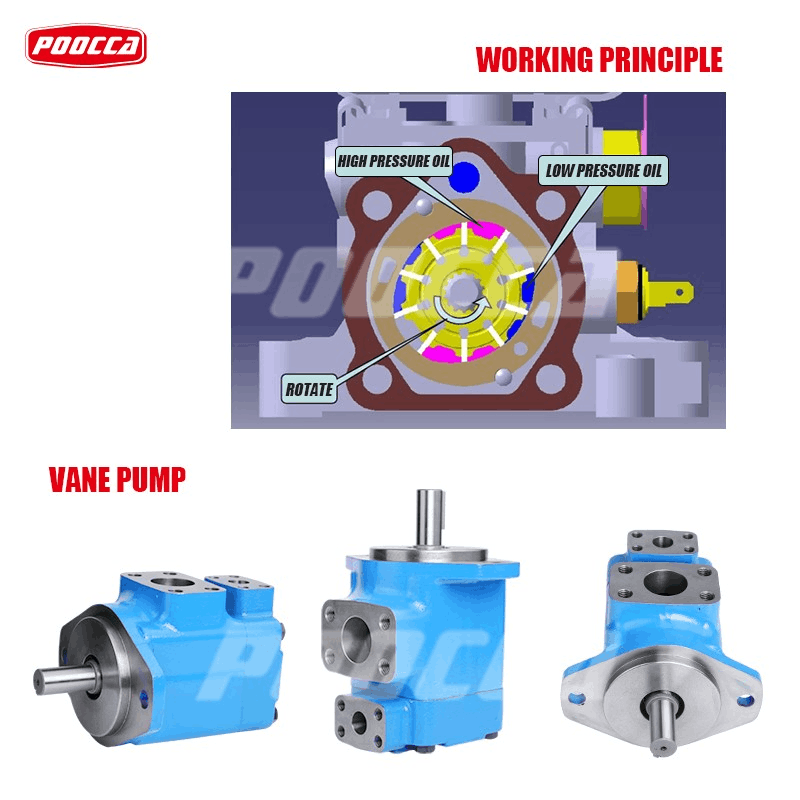

- Vane pumps provide better efficiency than gear pumps, but not as good as piston ones. Their strong points include flexible control options—such as pressure compensation, load sensing, and variable displacement—plus much quieter operation. Vane pumps work well in lots of industrial places. Still, they face limits with very thick fluids under very high pressure.

- Piston pumps reach the top efficiency (up to 95%) and manage tough high-pressure situations with many control choices. Downsides include higher starting and repair costs. They also have more complicated service because some mechanical parts wear out easily.

Q: What Happens When Pump Rotation Is Reversed?

A: Changing the rotation direction leads to different outcomes depending on the pump’s design and type. Usual problems include:

- Much lower flow or even no flow at all

- Louder running noise

- Early wear or breakdown of seals

- Faster damage to bearings or their failure

- Possible impeller coming loose, which causes inside damage

Some internal gear pump models allow two-way rotation. They permit switching directions or steady work in either way without big troubles.

Q: Where Is the Pump Located Within a Hydraulic System?

A: In typical hydraulic diagrams and real setups, the pump sits between the fluid reservoir and the prime mover (motor or engine). This spot gives direct access to the inlet for pulling in fluid and links to the system for sending out pressurized fluid.

Diagrams show the motor with an “M” inside a circle. A curved arrow marks the shaft rotation direction. Hydraulic pumps show up as a circle with a filled triangle pointing toward the flow. An open triangle means a pneumatic compressor, not a hydraulic pump.

Q: Why Did the Vane Pump Stop Flowing?

A: Vane pump breakdowns often come from overload, inside leaks, or clear outside events that basic checks can spot. More than 80% of vane pump problems link straight to dirty hydraulic fluid.

Keeping fluid clean stands out as the cheapest way to maintain pumps. Spending on good filters pays off quickly through longer pump life, steady work, and less frequent oil changes.

For more details on controlling contamination in vane pumps, materials like Eaton’s Guide to Systemic Contamination Control offer full advice.

Q: What Is the Pressure on a Vickers Vane Pump?

A: Vickers VMQ series vane pumps provide continuous pressure ratings up to 293 bar (4,250 psi) in the 25-frame size. Displacements go up to 488 cm³/r (29.78 in³/r) in triple pump setups. These support tough jobs with steady high-pressure results.

POOCCA Values Quality Pumps

Hydraulic pumps stay at the center of creating useful fluid power in many industries. Stress on excellent quality and trusted service keeps systems running smoothly.

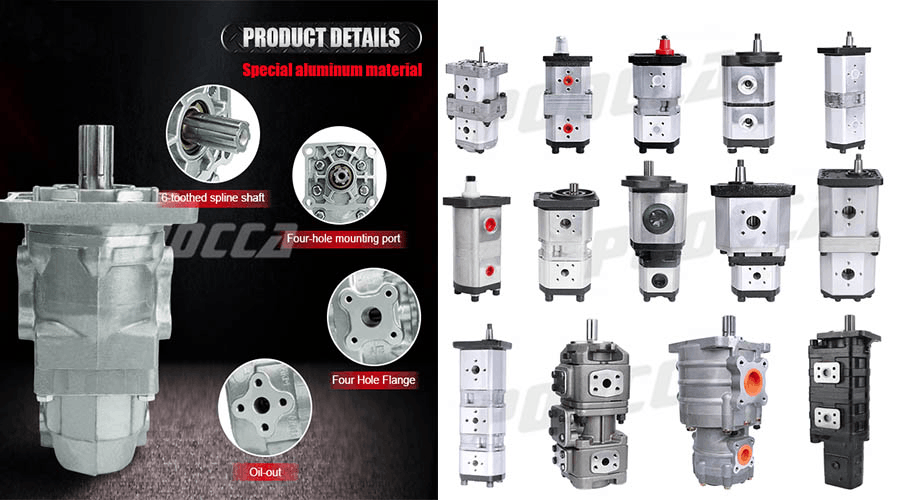

POOCCA Hydraulic (Shenzhen) Co., Ltd. keeps strict rules in manufacturing. This covers gear pumps, piston pumps, vane pumps, motors, valves, and accessories. The company combines R&D, production, sales, and maintenance. It has more than 20 years of experience since 2006. Products ship to over 120 countries. Offerings include matches and replacements for top brands such as Vickers, Rexroth (A10VSO series), Parker, Yuken, Denison, and others. All come at factory-direct quality levels.

POOCCA holds four firm promises:

- Exceptional customer support

- Superior product quality

- Reliable supply partnerships

- Prompt product availability

These ideas, together with wide product ranges including Vickers-compatible vane pumps, Rexroth A10VSO piston pumps, and different gear and vane setups, allow confident supply to distributors and manufacturers around the world.

Other Frequently Asked Questions

Q: How does contamination affect vane pumps?

A: Dirty fluid causes over 80% of vane pump failures. It leads to lower flow, wear, and full stoppage. Regular filtration stops these problems.

Q: Can vane pumps handle high pressure?

A: Yes, models like Vickers VMQ series support continuous pressures up to 293 bar (4,250 psi). They have variable displacements for flexible use.

Q: What causes vane pump noise?

A: Noise often comes from cavitation, contamination, or wrong setup. Vane designs usually make less noise than gear pumps.

Partner with a Trusted Hydraulic Manufacturer and Supplier

Manufacturers, suppliers, and distributors looking for reliable hydraulic parts gain from working directly with the factory. POOCCA acts as a complete manufacturer, supplier, and factory focused on high-quality gear pumps, piston pumps, vane pumps, and related systems. With factory-direct pricing, quick delivery, 12-month warranties, and customization choices (including ODM/OEM solutions), POOCCA helps equipment builders and system integrators in construction, agriculture, mining, and industrial fields.

Contact the POOCCA team today for quotes, technical details, or custom hydraulic solutions. Reach out by email at sales@kamchau.com or phone/WhatsApp at +86 18927498997 to talk about needs and get top components at good value.