In heavy machinery and industrial equipment, exact control over huge loads decides how well things work. Hydraulic systems depend on parts that provide safety, dependability, and good performance. Among them, the pilot-operated check valve serves as an important piece. This guide looks at how these valves work, their design, and where they get used. It pulls from accepted engineering ideas and common industry habits.

What Exactly is a Pilot-Operated Check Valve?

A pilot-operated check valve lets fluid move freely in one direction. At the same time, it stops flow from going the opposite way, much like a regular check valve. The special thing about it comes from an outside pilot pressure signal. This signal opens the valve and allows reverse flow when needed.

That ability helps release trapped fluid in a careful way. Because of this, the valve becomes very important for holding loads steady in hydraulic circuits.

The design keeps actuators, like cylinders, locked tightly under load. They stay that way until a clear signal starts motion. This strong locking method works better than ordinary directional control valves at keeping positions steady.

As a key safety part, the valve stops any unwanted actuator movement. It gives solid protection against hose breaks or pressure drops on the downstream side.

How Does a Standard Check Valve Work Compared to a Pilot-Operated Valve?

A standard check valve works in a simple, passive manner. It permits flow in just one direction. Fluid pressure pushes past a spring-loaded poppet or ball to open the forward path. Reverse pressure helps close it even tighter.

On the other hand, a pilot-operated check valve uses active control with a pilot piston. Forward flow happens freely, the same as in a standard valve. But reverse flow needs pilot pressure to move the main poppet aside.

This extra part allows control from a distance. It increases flexibility in changing systems.

Feature Comparison

Standard Check Valve

- Primary Function: Allows flow in one direction only

- Control Mechanism: Passive (forward pressure opens)

- Key Components: Body, poppet/ball, spring

- Common Use Case: Backflow prevention, isolation

- Complexity: Simple

Pilot-Operated Check Valve

- Primary Function: Allows flow in one direction; permits reverse with pilot signal

- Control Mechanism: Active (pilot signal enables reverse flow)

- Key Components: Body, poppet/ball, spring, pilot piston

- Common Use Case: Load-holding, cylinder locking, safety circuits

- Complexity: Moderately complex due to pilot mechanism

Why is a Pilot Signal Crucial for Pilot Valve Operation?

The pilot signal brings the smart control needed for proper action. It travels through a separate line. Pilot pressure then pushes on the piston. This action lifts the main poppet even when load pressure holds it down.

The pilot ratio—usually shown as a number like 4:1—sets the mechanical benefit. With this, a smaller pilot pressure can handle bigger system pressure.

Steady pilot supply leads to expected results. Too little pressure stops the valve from opening. Unexpected signals can cause early release.

Designers must focus on clean and steady pilot lines. That step supports the best safety and performance.

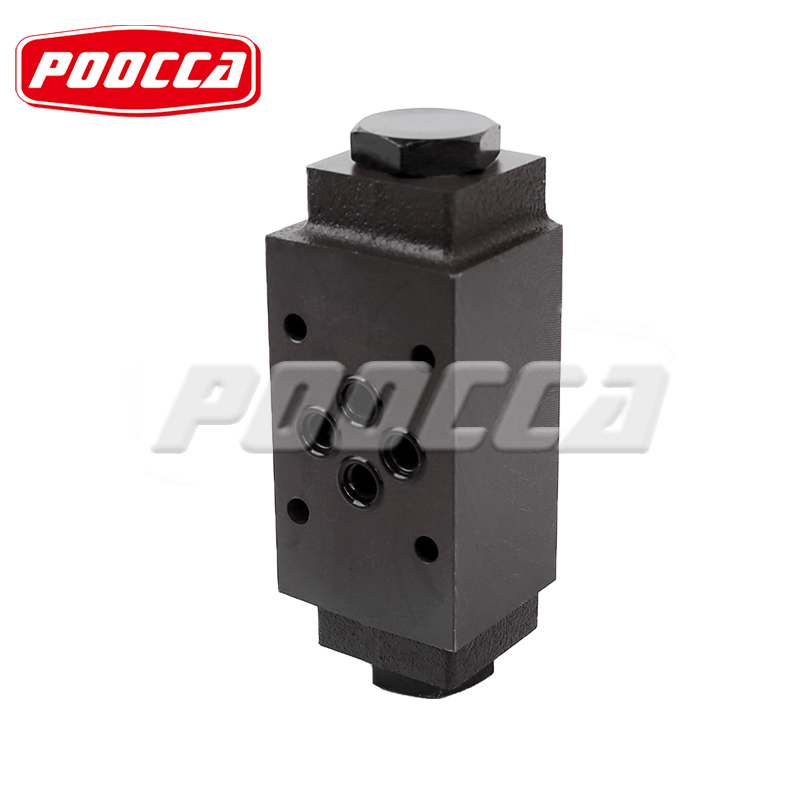

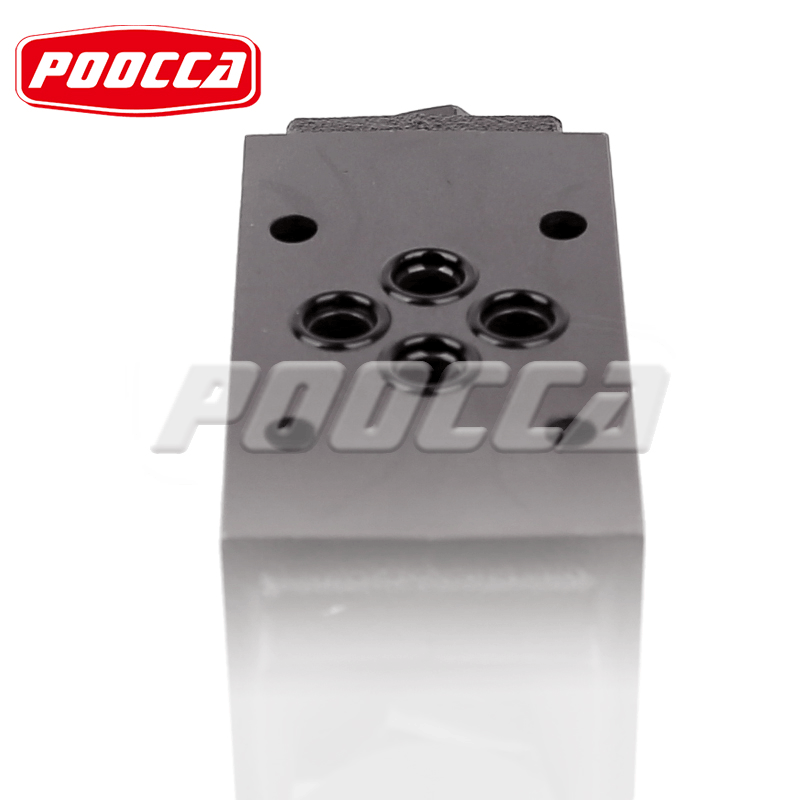

What Are the Key Components of a Hydraulic Pilot Check Valve?

Core elements include:

- Valve Body: Strong steel or ductile iron housing. It has main ports and a pilot port. The body handles high pressure well.

- Poppet (or Ball): Carefully made sealing piece that stops reverse flow.

- Spring: Keeps the poppet closed when no flow exists.

- Valve Seat: Tough surface that prevents leaks.

- Pilot Piston: Moved by pilot pressure to push the poppet open for reverse flow.

Close fits and good materials in these parts help ensure lasting reliability and very little leakage.

Can You Explain the Working Principle of a Pilot-Operated Check Valve?

Operation happens in three main modes:

- Free Flow Mode: Forward pressure beats the spring force. It opens the poppet fully so fluid reaches the actuator without limits.

- Checked (Blocked) Mode: When flow stops, the spring plus load pressure seats the poppet again. Fluid gets trapped, and the actuator locks in place.

- Pilot-to-Open Mode: Pilot pressure pushes the piston. This unseats the poppet and lets reverse flow happen in a controlled manner. Flow continues until the signal stops.

This order allows safe holding and then planned release.

What are the Common Types of Pilot-Operated Check Valves?

Different setups fit various circuit needs:

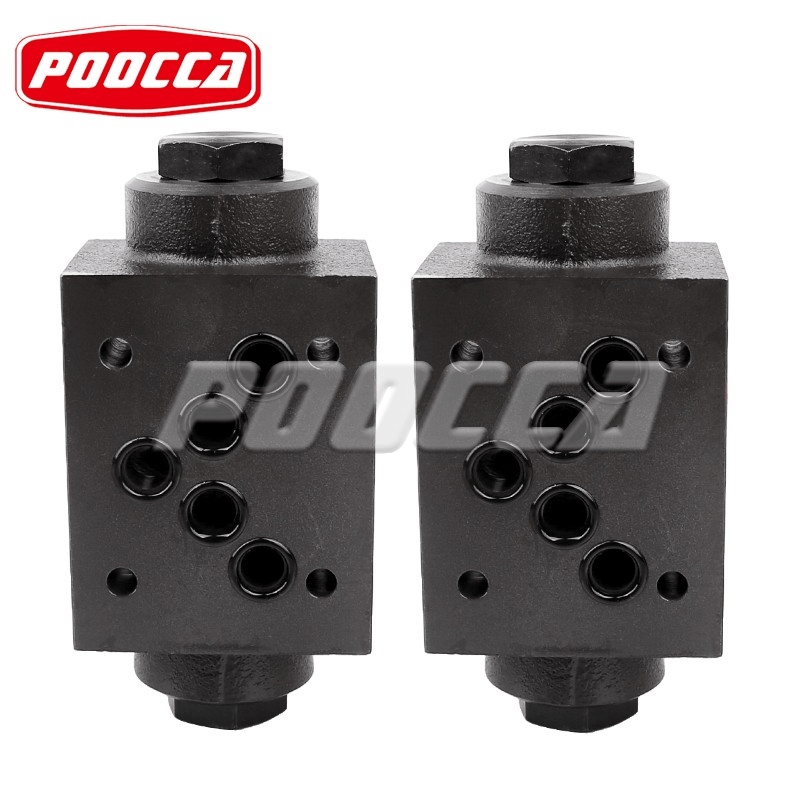

- Single Pilot-Operated Check Valves: They manage one flow path. These work well with single-acting actuators.

- Double Pilot-Operated Check Valves: These combine two units for double-acting cylinders. They often use cross-piloted lines for smooth extension and retraction.

- Modular and Cartridge Valves: Compact styles like MPW, MPB, MPA series fit nicely into manifolds. They cut down on piping and possible leak spots.

Where Are Pilot-Operated Check Valves Used in Hydraulic Systems?

These valves appear in many fields that need firm load control:

- Material handling equipment (forklifts, cranes, aerial platforms) for holding loads up in the air.

- Vertical cylinders to stop drift in clamping or outrigger setups.

- Accumulator isolation for storing energy or handling shocks.

- Safety circuits in presses to hold actuators steady during power failure.

What Should You Consider When Selecting a Hydraulic Check Valve?

Important points for choosing include:

- Pressure and flow ratings that fit system needs.

- Pilot ratio that balances control with available pressure.

- Decompression features to reduce shock in high-pressure cases.

- Material and seal match with the fluid and surroundings.

- Certifications (e.g., ISO 9001) and clear information from the manufacturer.

How Do You Troubleshoot Common Issues with a Pilot Check Valve?

Frequent troubles and fixes:

- Leakage/Drift: Usually caused by dirt; clean the valve or change seals. Make sure filtration stays good.

- Failure to Open: Look at pilot pressure. Check lines for clogs. Confirm the ratio works for the setup.

- Jerky/Noisy Operation: This points to decompression shock. Choose valves with built-in fixes or change how pilot pressure gets applied.

Additional Considerations for Modern Hydraulic Systems

Putting these valves into modular manifolds improves space use and overall efficiency. They pair well with proportional controls. That setup gives better fine-tuning in newer systems.

Newer materials stand up better to very hot or cold conditions and tough fluids.

Why Partnering with a Reliable Hydraulic Valve Manufacturer is Essential?

Quality, steady output, and good support shape long-term success. Trustworthy manufacturers offer proven certifications, accurate engineering, and quick help.

Smooth shipping and custom choices cut downtime. They also improve how everything fits together.

Key Takeaways to Remember

- Function: Permits one-way flow with pilot-enabled reverse capability.

- Purpose: Ensures safe load-holding and prevents unintended movement.

- Key Feature: Pilot ratio governs opening requirements.

- Selection is Crucial: Match to pressure, flow, and application specifics.

- Applications are Widespread: Essential in handling, construction, and safety systems.

- Supplier Reliability Matters: Prioritize quality assurance, communication, and delivery.

Frequently Asked Questions (FAQ)

What does pilot ratio mean in these valves?

Pilot ratio indicates the multiplication factor; for example, a 4:1 ratio allows 1 unit of pilot pressure to overcome 4 units of load pressure.

When is a decompression feature recommended?

In high-pressure systems with large trapped volumes, to prevent shock and ensure smooth operation.

Can pilot-operated check valves be used in cartridge configurations?

Yes, modular cartridge types like MPW, MPB, and MPA integrate easily into manifolds for compact systems.

What maintenance is required for these valves?

Regular fluid filtration, periodic inspection for contamination, and seal replacement as needed to prevent leakage.

Partner with a Trusted Hydraulic Valve Manufacturer and Supplier

For procurement teams and system integrators seeking high-quality pilot-operated check valves, including modular types such as MPW, MPB, and MPA series, POOCCA stands as a leading manufacturer, supplier, and factory. With extensive experience in R&D, production, and global export, POOCCA delivers reliable hydraulic valves at competitive factory prices, supported by customization options, fast delivery, and comprehensive technical assistance. Contact the POOCCA team today to discuss specifications, request quotes, or arrange consultations for your hydraulic system requirements. Reach out via sales@kamchau.com or +86 18927498997 to secure components that enhance performance and safety.