Internal gear pumps form a key part of positive displacement pumping technology. They provide dependable fluid movement in tough industrial settings. These pumps handle a wide variety of fluids well. They work with thin solvents as well as thick substances like resins and adhesives. The design gives steady results. This makes them essential in fields that need accuracy and strength.

Introduction to Internal Gear Pumps

Internal gear pumps work as rotary positive displacement devices. They use the contact between an outer rotor and an inner idler gear to push fluids along. The idea came from pump engineering advances more than a hundred years ago. This setup creates smooth flow without pulses. The pumps keep even output even when pressure changes. They support uses where dependability and good performance are most important.

How Internal Gear Pumps Function

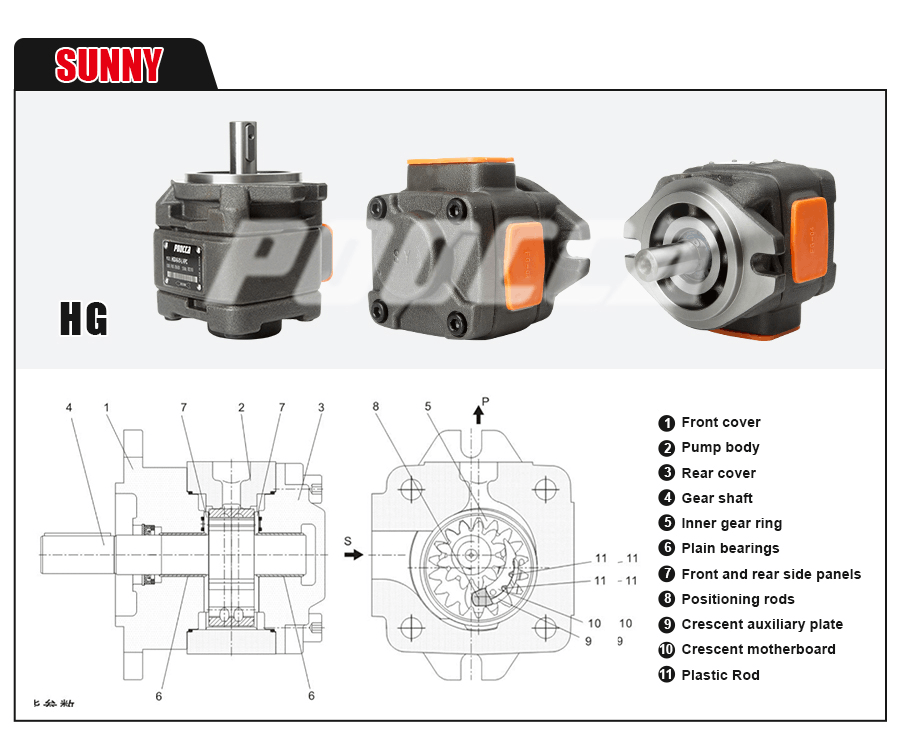

The working idea depends on gears fitting together inside a closed space. The outer rotor has extra teeth. It turns the smaller inner idler gear. Fluid comes in through the suction port during rotation. It fills spaces made between the gear teeth. A fixed crescent-shaped part divides the suction and discharge areas. This stops backflow. At the same time, the gears make volumes that grow and shrink.

As the turning goes on, those spaces get smaller on the discharge side. This pushes fluid out with force. The method captures an exact amount of liquid each time. It guarantees correct movement. The setup deals with different fluid features. It does this with little drop in efficiency. The crescent seal keeps the inlet and outlet sections apart.

Key Features of Internal Gear Pumps

Internal gear pumps include several special parts that boost how well they work:

- Rotary Motion: Steady gear turning creates even fluid flow with very little shake.

- Volume Control: Gears that fit together make sealed pockets for exact amount moved per turn.

- Low Pressure Zones: Expansion on the suction side builds a vacuum. This pulls fluid in well.

- Crescent Seal: This fixed piece keeps suction away from discharge. It cuts down on leaks and allows self-priming.

- Versatility: The setup works over wide ranges of temperature and thickness.

These qualities lead to strong and flexible pumping options. They fit hard situations.

Advantages of Using Internal Gear Pumps

Internal gear pumps bring several practical gains. These improve how the system runs and how long it lasts:

- High Efficiency: Almost steady flow rates cut down on energy use. Performance stays mostly free from system pressure.

- Self-Priming Capability: The setup clears air from pipes. It makes sure starting works well even after downtime.

- Robust Construction: Tough materials stand up to scratching or eating away by fluids. This lengthens life in rough places.

- Wide Viscosity Range: Good control of thin solvents up to thick polymers cuts the need for many pump kinds.

- Quiet Operation: Gentle gear contact lowers sound. This helps in closed or sound-sensitive spots.

- Precise Flow Control: Changes in speed allow exact measuring for dosing or balanced tasks.

- Low Maintenance Requirements: Fewer parts that move and basic insides reduce stoppages and fix costs.

These gains make internal gear pumps a top pick for tasks that need steady work with little upkeep.

Advanced Design Considerations in Internal Gear Pumps

Beyond basic workings, current internal gear pumps add improvements for special uses. Choices of materials like hardened steels or alloys that resist corrosion handle strong fluids. Sealing choices include mechanical seals or magnetic drives. They stop leaks in dangerous areas. Adding variable speed through drives permits changing flow as needed. This makes best use of energy in systems with changing demands.

Applications of Internal Gear Pumps

Internal gear pumps fit many industries because they are dependable and flexible with fluids:

- Chemical Processing: Moving resins, adhesives, and harsh chemicals with exact control.

- Food and Beverage: Dealing with thick syrups, oils, and clean fluids while keeping hygiene rules.

- Pharmaceuticals: Exact dosing of active parts and helpers in clean processes.

- Oil and Gas: Pumping crude, lubricants, and fuel oils in upstream and downstream work.

- Pulp and Paper: Shifting thick slurries and coatings without harm from shear.

Other areas cover paints and coatings for mixing pigments, plus polymer processing to aid extrusion.

Choosing the Right Internal Gear Pump

Picking the right model means checking several key factors:

- Viscosity of the Fluid: Fit pump gaps and materials to fluid thickness for best results.

- Flow Rate Requirements: Figure displacement from system needs and turning speed.

- Temperature Conditions: Make sure parts handle heat changes and keep seals tight.

- Material Compatibility: Pick wetted parts that resist chemical harm or wear.

- Maintenance Needs: Choose setups with easy-to-reach insides for simple service.

Looking at performance curves and use data helps match goals well.

Maintenance and Longevity Best Practices

Regular checks on seals, bearings, and gears stop early breakdown. Watch for odd sounds or pressure falls to spot wear. Good lubrication and clean filters lengthen part life. Correct alignment at setup avoids extra strain.

Conclusion

Internal gear pumps mix clever design with useful gains. They offer efficient and dependable fluid handling for many industrial uses. Their skill at giving even flow, managing different thicknesses, and running quietly makes them a worthwhile part in current systems.

POOCCA

POOCCA stands as a leading manufacturer, supplier, and factory of hydraulic pumps, including high-quality internal gear pumps and external gear pumps. With over 20 years of experience, POOCCA provides comprehensive solutions, factory-direct pricing, fast delivery, customization options, and technical support for industrial needs worldwide.

Frequently Asked Questions (FAQ)

What distinguishes internal gear pumps from external gear pumps?

Internal gear pumps have an inner idler gear that meshes inside an outer rotor. This creates smoother flow without pulses. It suits high-viscosity or exact uses. External gear pumps rely on two gears that mesh outside. They allow faster speeds but may show some pulsing.

Can internal gear pumps handle abrasive fluids?

With right material choices like hardened parts, these pumps deal with mildly scratching media well. But very harsh abrasives might need special setups.

How do temperature variations affect performance?

Big temperature swings change fluid thickness and how materials grow. Pumps built with thermal adjustment keep good efficiency over wide ranges.

What maintenance intervals are recommended?

Times vary with conditions. Still, checks every 6-12 months for seals, bearings, and fluid state help keep things running well.

Are internal gear pumps suitable for metering applications?

Their exact displacement allows accurate measuring. This works especially well with variable speed controls.

Partner with a Trusted Hydraulic Gear Pump Manufacturer and Supplier

Clients looking for reliable internal gear pumps gain from working with a solid hydraulic solutions provider. POOCCA, as a dedicated manufacturer, supplier, and factory, offers a full range of gear pumps, including internal and external types, with competitive factory pricing, rapid delivery, 12-month warranties, and customization for specific industrial requirements. Contact POOCCA today for expert consultation, product specifications, quotes, or tailored hydraulic system support to enhance operational efficiency.