Hydraulic systems form the base for many industrial and mobile machines. The hydraulic pump stands as a key part in sending power. The Vickers hydraulic vane pump stands out with steady efficiency, strong build, and wide use in tough settings. This guide looks closely at the Vickers hydraulic vane pump. It covers performance details, main uses, and important care steps. It works as a main source for improving systems or learning how the pump helps different fields.

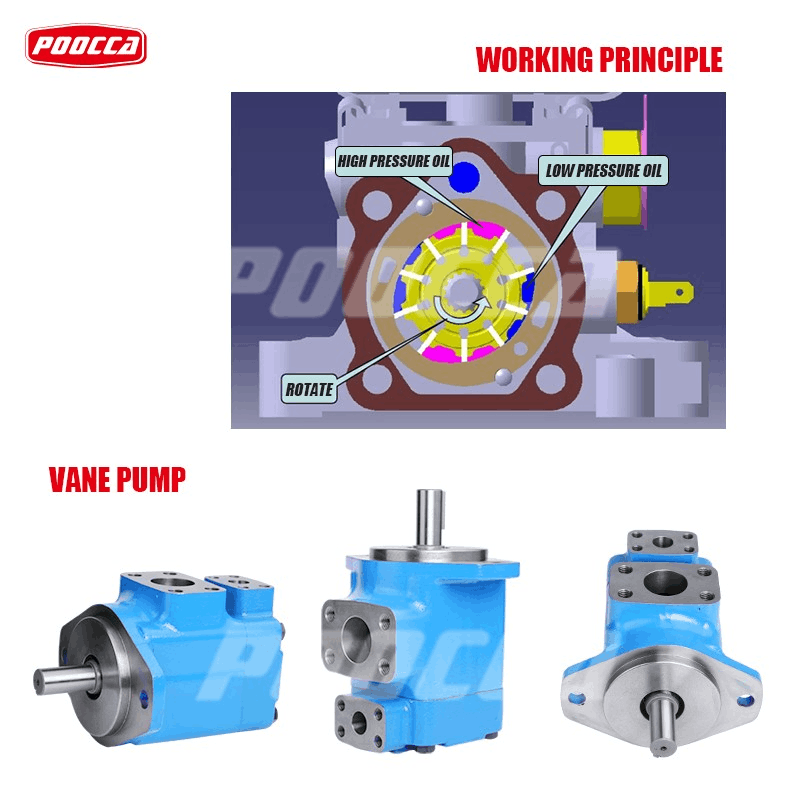

Understanding Vickers Hydraulic Vane Pump Design and Operation

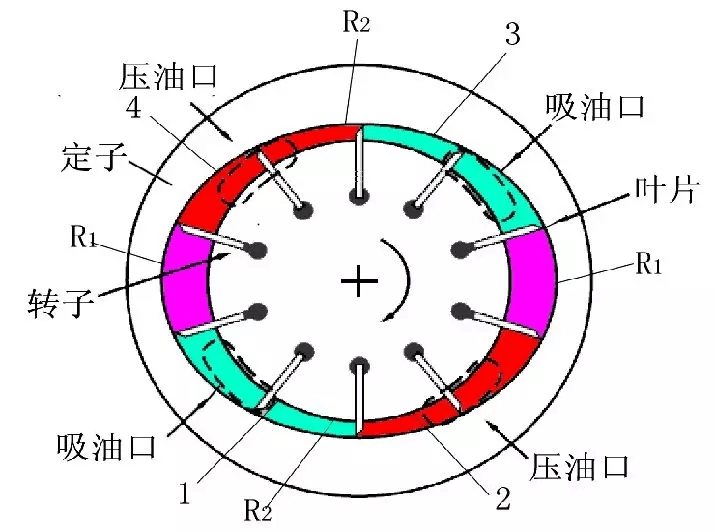

A Vickers vane pump uses a rotor with sliding vanes inside an off-center cam ring. This setup makes chambers that change size. As the rotor turns, vanes move out and in. They pull fluid in on one side, squeeze it in the middle, and push it out at the exit.

- Flow Rate: Goes from 10 to 300 liters per minute (L/min). You can match different system sizes by picking the right model.

- Operating Pressure: Handles up to 210 bar (around 3,000 psi). It fits well for medium to high pressure needs.

- Speed Range: Runs smoothly from 600 to 3,000 revolutions per minute (RPM). Best efficiency comes when you balance output and part wear.

- Displacement: Covers 2 to 150 cubic centimeters per revolution (cc/rev). This sets how much fluid moves each cycle.

These traits allow small, reliable fit in aerospace parts, mobile gear, and complex industrial hydraulic setups.

Key Components of Vickers Vane Pumps and Their Functions

- Rotor: Gives exact drive to the vanes. It is built to cut down side-to-side and up-down shifts. It also reduces shakes. Speed can match demand up to 3,600 RPM in good models.

- Vanes: Slide out to seal against the cam ring. They use tough, wear-proof materials. These hold up under pressures close to 200 bar (about 2,900 psi).

- Cam Ring: Sets the off-center path for size changes. It is shaped to improve flow amount and smooth running.

- Port Plate: Guides inlet and outlet paths. Tight fits lower inside leaks. This keeps high efficiency.

- Pressure Plate: Keeps balance side-to-side and good seals during load changes. It boosts pump steadiness and life.

These parts work together for exact and strong work under heavy hydraulic loads.

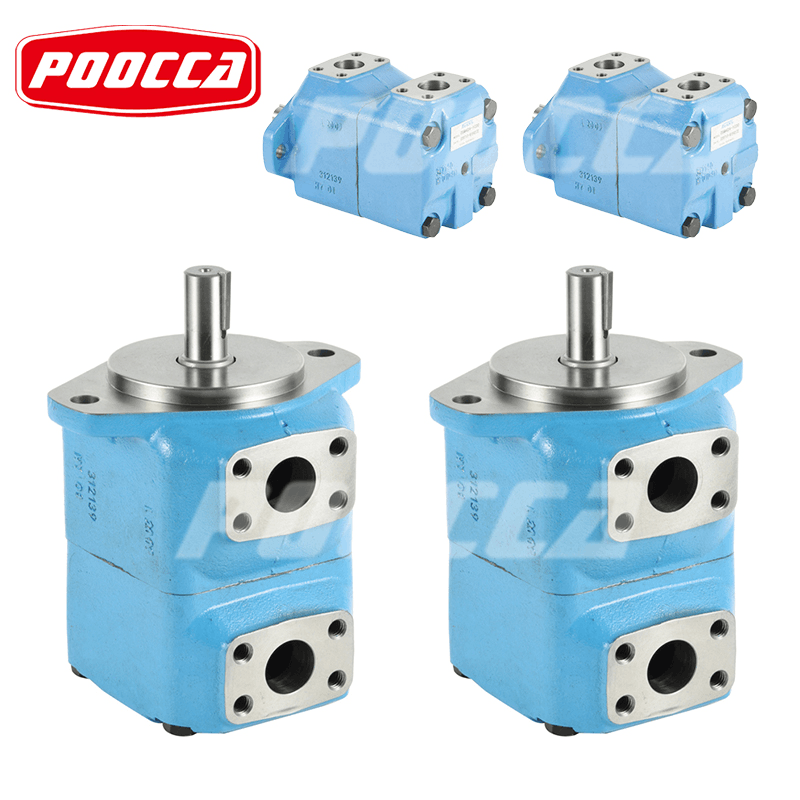

Differences Between Single Vane and Double Vane Pump Designs

Single-vane pumps have one rotor-vane set. They offer simple build. This suits moderate flow and pressure jobs. They often limit to around 2,000 psi and 40 GPM.

Double-vane pumps hold two rotor sets in one case. They reach higher flows and pressures. Many go past 2,500 psi and 50 GPM. They also give better volume efficiency, less shake, and quieter sound from better machining.

Single-vane types give low-cost work for normal tasks. Double-vane types handle tough, high-output hydraulic needs.

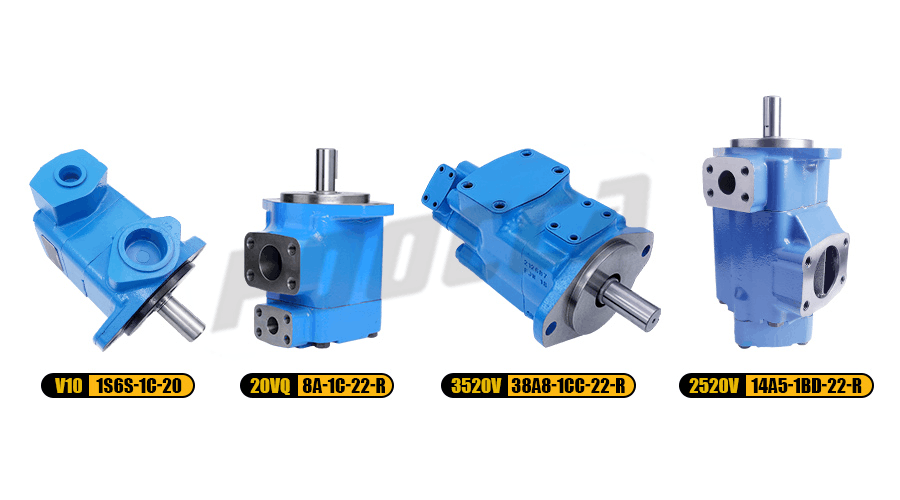

How to Identify Vickers Vane Pump Models and Product Codes

Decoding Vickers Pump Series and Model Numbers

Product codes hold key details for correct match and pick.

- Displacement: Shows output volume per turn.

- Pressure Rating: Sets safe max work level.

- Shaft Type and Orientation: Points to keyed, splined, or other kinds.

- Port Configurations: Tells inlet/outlet sizes and directions.

- Mounting Style: Sets how it attaches for system fit.

- Seal Type: Picks material for fluid type and heat levels.

For example, codes like “V20-1S-1C-11” show the V20 series. Then follow signs for shaft style, displacement size, port setup, and pressure class.

Understanding V10 and V20 Series Fixed Displacement Vane Pumps

The V10 and V20 series give reliable, small fixed displacement work.

- Displacement: V10 covers 0.3 to 1.3 cubic inches per revolution. V20 goes to 1.4 to 2.4 cubic inches per revolution.

- Maximum Pressure Ratings: V10 hits 2,000 PSI. V20 reaches 2,500 PSI.

- Operating Speed: Works steady from 600 to 2,400 RPM.

- Shaft Type Options: Has keyed and splined choices.

- Port Configurations: Flexible sizes for different flow needs.

These series fit well with material handling gear, accurate machine tools, and mobile hydraulic machines.

Comparing Vickers Pump Specifications Across the Range

- Displacement: V10 series 10-20 cm³/rev. V20 series 20-40 cm³/rev for bigger needs.

- Operating Pressure: Often rated to 207 bar (3,000 psi) across models.

- Flow Rate: V10 gives 10-25 L/min. V20 reaches up to 80 L/min.

- Efficiency: Keeps hydraulic efficiency over 85%. This cuts energy loss.

These differences let exact match to work needs.

What Are Common Applications and Industries for Vickers Vane Pumps?

Industrial Hydraulics Applications and Requirements

Vickers vane pumps do well in making, material moving, building, and pressing work. They give steady output.

- Manufacturing Systems: V20 series backs assembly lines and injection molding. It handles flows to 80 L/min and efficiency over 85%.

- Material Handling Equipment: V10 series suits conveyors and lifts. It needs reliable 25 L/min supply.

- Construction and Mobile Machinery: Powers excavators, loaders, and cranes under changing heavy loads.

- Industrial Presses: Delivers controlled force in metal shaping and stamping.

Mobile Applications for Vickers Hydraulic Pumps

These pumps show strength in farm, building, and handling gear in hard spots.

- Operating Pressure: Holds up to 3,000 psi.

- Flow Rate: Changes from 5 to 75 GPM.

- Temperature Range: Works well from -20°F to 250°F.

- Displacement: Has fixed and variable choices to fit power needs.

Pressure and Flow Specifications for Different Applications

- Agricultural Equipment: Max 3,000 PSI with 10-20 GPM for cylinder and motor work.

- Construction Machinery: Up to 4,000 PSI and 25-50 GPM for heavy tasks.

- Industrial Systems: 1,500-2,500 PSI and 5-15 GPM in exact assembly lines.

- Mobile Machinery: 15-75 GPM with pressures to 4,500 PSI for flexible work.

How to Maintain and Troubleshoot Vickers Vane Pumps?

Replacement Parts and Repair Solutions

Real replacement parts—vanes, seals, rotors, and bearings—must meet original fits. Common problems like low flow, uneven pressure, or odd noise often come from worn vanes, dirty fluid, or bad seals. Care includes following ISO 4406 cleanliness rules (usually 18/16/13), changing filters on time, and putting back together with right torque.

Improving Pump Efficiency and Serviceability

- Set up pipes and suction lines to stop cavitation and cut pressure drops.

- Do regular checks on parts that wear fast.

- Watch pressure, flow, temperature, and other signs against maker limits.

- Add variable frequency drives to save energy at low loads.

Regular use of these steps boosts reliable work and lowers sudden stops.

What Are the Performance Characteristics of Vickers Vane Pumps?

Maximum Pressure, Flow Rate, and RPM Specifications

- Maximum Pressure: 1,750 to 3,000 PSI (121-207 bar). Depends on model.

- Flow Rate: 3 to 75 GPM (11-284 L/min).

- Maximum RPM: 1,200 to 3,600 RPM.

Efficiency and Quiet Operation Features

Tight inside spaces raise volume efficiency. Special damping and fluid flow shapes cut noise and rough flow. This happens even at fast speeds. It lowers wear and lengthens service time.

Frequently Asked Questions (FAQs)

Q: What maintenance practices are essential for extending the life of a Vickers Vane Pump?

A: Keep fluid clean with good filters and regular checks. Look at housing for damage. Check drive alignment. Control work temperature. Follow fluid rules. Avoid cavitation with good inlet setup. Replace wear parts early.

Q: How to select the right Vickers Hydraulic Vane Pump for an application?

A: Look at needed flow amount, system pressure, fluid match, work cycle, and surroundings. VQ series fits high pressure. Other series suit certain flow needs.

Q: What are common troubleshooting steps for a Vickers Vane Pump that’s not performing properly?

A: Check fluid state and amount. Look at suction lines for air entry. Clean or change inlet filters. Find noise from cavitation, bad alignment, or wear. Check relief valve settings for pressure issues. Look at vanes and rotor for flow problems.

Q: How do Vickers vane pumps compare to piston pumps in hydraulic systems?

A: Vickers vane pumps make smoother, quieter flow with low-cost work up to about 3,000 psi. They resist dirt better. Piston pumps give higher efficiency at very high pressures (>4,000 psi). They work best in variable displacement cases. Choice depends on pressure needs, work type, control wants, and cost limits.

Source Reliable Vickers-Compatible Solutions from a Leading Manufacturer and Supplier

Industrial work and equipment builders who need high-performance Vickers-compatible vane pumps get benefits from precise replacements. These give original-level output at better costs. POOCCA as Manufacturer and Supplier, founded in 2006 with over 20 years of special experience, makes fixed and variable displacement vane pumps—including direct equivalents to Vickers V/VQ series (V10, V20, 20VQ, 25VQ, 35VQ, 45VQ) and double setups (2520VQ, 3520VQ, 4520VQ, 4535VQ). They feature displacements from 5.8 to 193 cc/rev, continuous pressures up to 210-250 bar, volumetric efficiencies over 90%, low noise work, and strong build for industrial, mobile, and heavy-duty settings. Made under strict quality checks with ISO rules, 12-month warranties, plenty of stock for fast send, and export to over 120 countries, POOCCA acts as a trusted factory-direct partner. Reach out via sales@kamchau.com or +86 18927498997 (WhatsApp supported) to list needs, get quotes, or ask for samples for system fit.