Gear Pumps: Simplicity and Durability

齿轮泵如何工作

齿轮泵 are wicked simple and totally popular for hydraulic systems, especially low-pressure tasks. They use two gears that mesh and whirl to make a vacuum. This yanks hydraulic fluid into the inlet and blasts it out the outlet. Two main kinds exist: external gear pumps, where gears bump against each other, and internal gear pumps, with one gear tucked inside the other.

Key Characteristics of Gear Pumps

Gear pumps pump out a steady flow rate, linked to how quick gears spin. But they’re not zesty with precision like other pumps. They shine for jobs that don’t need flow switches. They tackle low to medium pressure ranges. Some spiffy models can handle bigger pressures, though. Their no-muss setup means fewer moving pieces, so breakdowns are super rare. Plus, they’re a snap to mend and don’t cost heaps, making them a fave for basic hydraulic systems.

Applications of Gear Pumps

Gear pumps glow in places where low-to-medium pressure is plenty and simplicity rules. They’re all over farm machines, construction gear, and factory stuff needing moderate hydraulic power.

Piston Pumps: High Pressure and Precision

How Piston Pumps Work

活塞泵 use a crew of pistons sliding in cylinders to juice up hydraulic fluid. As pistons zip back and forth, fluid gets sucked in during the intake stroke and shoved out during the push stroke. Piston pumps come in axial or radial flavors, depending on piston lineup.

Key Characteristics of Piston Pumps

Piston pumps crank out mega high pressures, way past gear or vane pumps, often zooming over 400 bar (5800 psi). This makes them perfect for heavy-duty hydraulic jobs needing giant force. They offer variable displacement, so flow rate shifts to match system demands. These pumps are crazy efficient, dishing out snappy performance across varied pressures and flow rates. But their slick design makes them pricier and fiddlier than gear or vane pumps.

Applications of Piston Pumps

Piston pumps rock in high-pressure gigs craving pinpoint accuracy and efficiency. Picture huge construction machines, aerospace systems, industrial presses, and hydraulic setups needing massive power density.

Vane Pumps: Quiet and Versatile

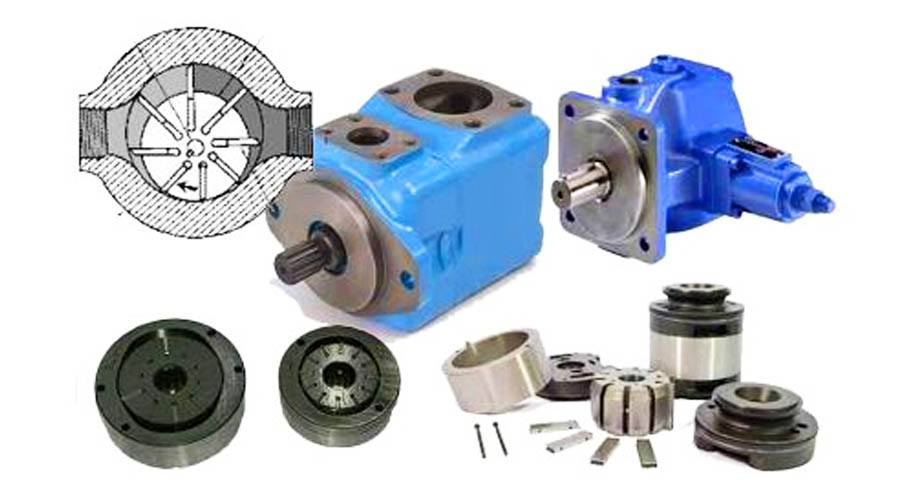

Vane泵如何工作

叶片泵 use whirling vanes that slide in and out of rotor slots to create hydraulic pressure. As the rotor spins, centrifugal force pushes vanes against the pump casing. This forms pockets that pull in and pressurize hydraulic fluid.

Key Characteristics of Vane Pumps

Vane pumps are rad for being hush-hush. Their sliding vane design trims pulsation, giving smoother fluid flow and less racket than gear or piston pumps. They handle medium pressure levels, up to 200 bar (2900 psi), with decent flow rates. They can be fixed or variable displacement, offering leeway for different hydraulic systems. But they’re choosy about dirt and might wear out faster than gear pumps if not kept clean. Still, they’re pretty simple to fix up.

叶片泵的应用

Vane pumps fit swell in jobs where quiet runs and smooth flow are huge. They’re used in car systems, plastic injection molding machines, and mobile gear with moderate hydraulic power needs.

Key Differences Between Gear, Piston, and Vane Pumps

Hydraulic pumps are the lifeblood of hydraulic systems. They flip mechanical energy into hydraulic energy to power machines across industries. Gear pumps, piston pumps, and vane pumps are the main players, each with nifty perks.

Gear pumps stand out for being simple and cheap but aren’t super sharp on accuracy. Piston pumps deliver awesome efficiency at high pressures with variable displacement but cost a bundle. Vane pumps offer quiet runs and smooth flows but might not last as long in harsh conditions.

为您的应用选择合适的泵

Picking between gear, piston, and vane hydraulic pumps depends on the job’s needs. Gear pumps are coolio for low-to-medium pressure systems that love toughness and low cost. Piston pumps are the top pick for high-pressure tasks needing precision. Vane pumps suit moderate pressure jobs where quietness and smooth operation are key.

For example:

- Use geartypes like CBK Series or Ronzio Z1 when you need compact size with good efficiency.

- Choose 活塞models like Rexroth A10VSO Series or Eaton PVXS when your system demands high pressure control.

- Opt for 叶片options like Parker T6/T7 or Yuken PV2R if quiet operation is paramount.

Request a Custom Hydraulic Pump Quote from POOCCA Today

Poocca液压(深圳)有限公司 launched in 2006. It’s a full-on hydraulic company digging into research, development, manufacturing, and sales of hydraulic pumps, motors, valves, and parts. With oodles of experience in power transmission, they’ve built a rock-solid name in the industry.

Need a reliable gear pump like the SGP2 series for forklifts or a high-performance piston pump like Rexroth A22VG for closed-circuit drives? POOCCA has it sorted. Get a quote from POOCCA.

They’ve dumped tons of cash into top-tier manufacturing tools, like CNC grinders, to whip up custom solutions for industries like construction. Their pro team helps sort out system needs—flow rate, pressure ranges—and guides to the best hydraulic pump models.