What Are Directional Control Valves?

阀 have a unique ability to control fluid within a hydraulic system. Among these, the hydraulic directional control valve (DCV) plays a critical role by managing the path of hydraulic fluid through a circuit. Directional Control Valves (DCVs) do so by directing the path of hydraulic fluid (flow) through a circuit. They are used to start, stop, slow, accelerate, and change the direction of motion in a cylinder.

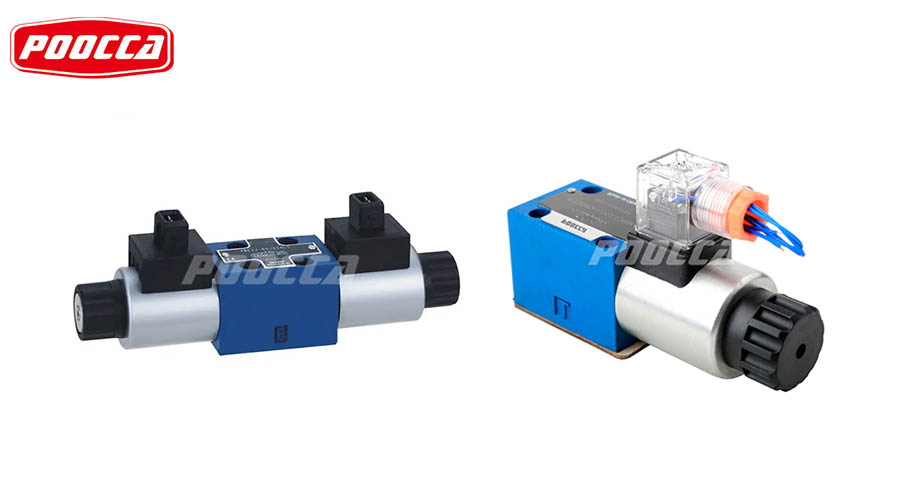

The internal mechanisms of DCVs vary and can include sliding spools, rotary spools, or ball valves. One of the most common valve types are Sliding Spool Valves. They have different flow path configurations depending on the sliding spool design. These designs allow DCVs to shift flow suddenly and precisely, earning them nicknames like “switching” or “bang-bang” valves due to the abrupt nature of their operation.

When Are Directional Control Valves Used?

DCVs are essential with any hydraulic circuits to create bi-directional motion for a hydraulic actuator, or anything with a motor is going to benefit from their use, as they can be actuated into a variety of discrete positions for many functions. Their main function is to control when and how hydraulic actuators move—whether starting, stopping, accelerating, decelerating, or changing direction.

They are also employed for other purposes such as isolating branches of a circuit, venting relief valves, or allowing free flow from pumps back to reservoirs. They work to actuate using these four methods:

Manual

Mechanical

Solenoid-Operated

Pilot-Operated

This versatility makes DCVs indispensable in industries ranging from construction machinery and agriculture to aerospace and manufacturing.

How Does a DCV Work?

Broadly, DCVs have a general order of operations once called into action by hydraulic fluid flow. Upon activation, the valve shifts from its neutral position to perform its intended function—allowing or restricting fluid movement—and then returns to neutral once the task is complete. This action occurs instantaneously, causing fluid to accelerate and decelerate.

The specific behavior depends on several factors including spool type and positioning as well as the actuation method used. For example, solenoid-operated valves use electromagnetic force while pilot-operated versions rely on pressure signals.

Check Valves

Check valves are among the simplest forms of directional control valves. Check valves, for example, are binary directional control valves that allow fluid to flow in one direction while preventing it to flow in the opposite direction. This one-way functionality is critical in applications where reverse flow could damage equipment or disrupt operations.

A common variation is the spring-loaded check valve. Spring-loaded check valves work like this:

The flow enters the input port and the pressure pushes the disc open (A-B)

The spring closes the disc after enough back pressure is reached (C-D)

These valves are often found in pump discharge lines and other areas where backflow prevention is essential.

Spool-Type Valves

Spool-type directional control valves offer more complexity and flexibility than check valves. Spool-type valves are more complex, and that complexity has proven to be useful in complex hydraulic systems. They feature internal spools that slide within precision-machined housings to align ports in various configurations.

For example, levers on spool valves have the option of shifting to two or more positions for routing fluid between inlet and outlet ports, which are sometimes referred to as “ways.” The most common configuration is the 4/3-way valve—four ports with three spool positions—but simpler versions like 4/2-way also exist.

Let’s take a look at the simpler 4/2-way directional control valve, in which the two positions of the spool lever simply allow or restrict flow. The valve is encased in housing for precision.

These versatile designs make spool valves ideal for controlling complex actuator movements in industrial machinery.

Spring-Loaded Check Valves

Spring-loaded check valves provide automatic control without external actuation. Their internal spring mechanism ensures that fluid flows only when needed and prevents unwanted backflow when pressure drops.

The spring closes the disc after enough back pressure is reached (C-D), making them highly reliable under varying operational pressures. These characteristics make them suitable for safety-critical systems where maintaining unidirectional flow integrity is crucial.

DCV Troubleshooting and Resources

Despite their robust design and functionality, directional control valves can face operational issues over time—often due to contamination. Directional control valves keep fluid in a standby mode, preventing its flow from within the system until it’s needed to move and perform its designed function.

Contaminants such as dirt or water can compromise performance significantly. The best way to avoid DCV problems, or failure, is to prevent system contamination.

Keeping the oil clean, cool, and dry (preventing water contamination) will prevent most DCV failures and promote the longevity of the DCVs in the hydraulic system.

When troubleshooting becomes necessary or replacement parts are required quickly, trusted repair resources offer support across all major brands.

Custom Hydraulic Directional Control Valves Quote from POOCCA Today

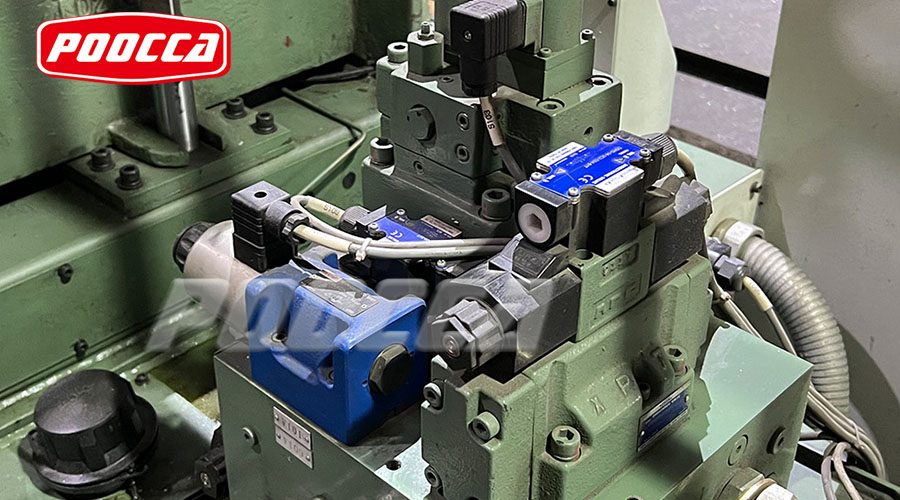

Poocca液压(深圳)有限公司 was established in 2006, bringing over two decades of expertise in designing high-performance hydraulic solutions. With an 8,000-square-meter factory equipped with CNC gear grinders and CAT computer-controlled testing machines,POOCCA offers tailor-made solutions for industries including construction machinery, agriculture equipment, injection molding systems, among others.

Customers seeking reliable hydraulic directional control valve solutions benefit not only from advanced manufacturing but also from expert consultation.At POOCCA, our strength is our dedicated team of over 300 professionals, including 70 seasoned sales experts who help clients find customized answers quickly.

Whether you need standard models like P40/P80/P120 series directional control valves or require fully customized units,POOCCA provides product customization services tailored specifically for your application requirements.

From pre-sales technical consulting through post-sales maintenance support,we at POOCCA provide you with one-stop service as much as possible. Request your quote today for high-efficiency hydraulic directional control valve systems engineered by an industry leader committed to quality and innovation.