液压电动机 are super important for machines. They turn liquid power into spinning motion. Two common types are bent axis and axial piston hydraulic motors. Each has special strengths for different jobs. This article looks at their designs, how they work, and what they’re best for. It helps you pick the right one for your needs.

Overview of Hydraulic Motor Designs

Hydraulic motors use liquid pressure to spin things. They power machines in farming, building, and factories. Both bent axis and in-line axial piston motors use pistons to move. But their setups make them act differently. This affects how well they work.

Bent Axis Motor Design

Bent axis motors have a cylinder block tilted compared to the drive shaft. The tilt can go up to 40°. This angle lets you control how much liquid moves, so you can adjust power and speed easily. Their small size makes them great for tight spaces where you need strong power.

In-Line Axial Piston Motor Design

In-line axial piston motors, also called swash plate motors, have a cylinder block lined up straight with the drive shaft. A swash plate tilts to move pistons, usually up to 20°. This makes the motor simple to fix and very dependable.

Performance Characteristics

Displacement Range and Torque/Speed Flexibility

Bent axis motors are great at changing liquid flow. Their 40° angle gives them twice the range of in-line motors. This means they can switch from strong lifting to fast spinning easily. For example, they can lift heavy stuff and then move quickly to a new spot.

In-line motors have less tilt, so they’re not as flexible. But some can go to zero flow, which is perfect for things like changing drive modes in machines.

Maximum Operating Speed

Bent axis motors, with light pistons, spin faster than in-line motors of the same size. Their angled setup lowers resistance, making them good for fast jobs like winches or fans.

In-line motors usually spin slower. Their swash plate design limits how fast they can go.

Torque Output and Stall Performance

Bent axis motors give about 5% more starting power than in-line motors of the same size. This starting power, called stall torque, helps when starting from a stop. It makes them awesome for tough jobs like excavators or presses.

In-line motors have a bit less starting power. But they still work great for steady jobs like conveyors or farm machines.

Efficiency at High Pressures

Both motors handle high pressure well. But bent axis motors often save more energy across different loads. Their adjustable flow helps use power wisely. In-line motors might lose a little efficiency in extreme conditions because they can’t adjust as much.

Design and Construction Details

Piston and Cylinder Dynamics

In bent axis motors, pistons sit in a tilted cylinder block. This cuts down on rubbing but can stress shaft bearings over time if not checked.

In-line motors have pistons moving straight along the shaft. This causes less bearing stress and makes them more reliable for steady work.

Material and Component Considerations

Both motor types use strong stuff like steel and bronze to handle big pressures and loads. Bent axis motors might use light pistons for speed. In-line motors focus on tough parts to last a long time.

Environmental and Operational Considerations

Temperature and Fluid Compatibility

Bent axis motors make more heat when running. They need good cooling systems. In-line motors handle temperature changes better. But both need the right hydraulic fluids with high viscosity to work well.

Duty Cycle and Load Variations

Jobs with changing loads are perfect for bent axis motors. Their flexibility helps a lot. In-line motors are better for steady jobs where you need consistent power more than changes.

申请适用性

Bent Axis Motor Applications

- 移动设备: Excavators, skid-steer loaders, and forestry machines use bent axis motors. Their wide power range makes them great for active tasks.

- Industrial Systems: Fast jobs like hydraulic presses, winches, and fan drives love bent axis motors for their speed.

- Marine and Offshore: Boat propellers and deck tools use bent axis motors for their small size and strong power.

In-Line Axial Piston Motor Applications

- 农业机械: Tractors, harvesters, and sprayers use in-line motors. They’re reliable and can hit zero flow.

- 建筑设备: Concrete pumps and compactors like in-line motors for their toughness and simple design.

- Material Handling: Forklifts and conveyors use in-line motors for steady work and low upkeep.

Maintenance and Serviceability

Maintenance Requirements for Bent Axis Motors

Bent axis motors might need more bearing checks. Listening for odd noises or shakes can spot problems early. Keeping things lined up right helps avoid wear.

Maintenance Requirements for In-Line Motors

In-line motors are easier to care for because they’re simpler. Check fluid levels, seals, and the swash plate often to keep them running. Their strong bearings usually mean longer times between fixes.

FAQ

How do I choose between bent axis vs. axial piston hydraulic motors?

Think about your job’s needs. If you need changing speeds and loads, pick bent axis. For steady work where simple is better, go with in-line.

Which motor type handles higher speeds better?

Bent axis motors spin faster than in-line motors of the same size.

Are both types suitable for high-pressure environments?

Yes. Both work well in high pressure, but bent axis might save more energy in changing conditions.

What about maintenance frequency?

Bent axis motors need more checks because they’re complex. In-line motors are simpler, so they’re easier to maintain.

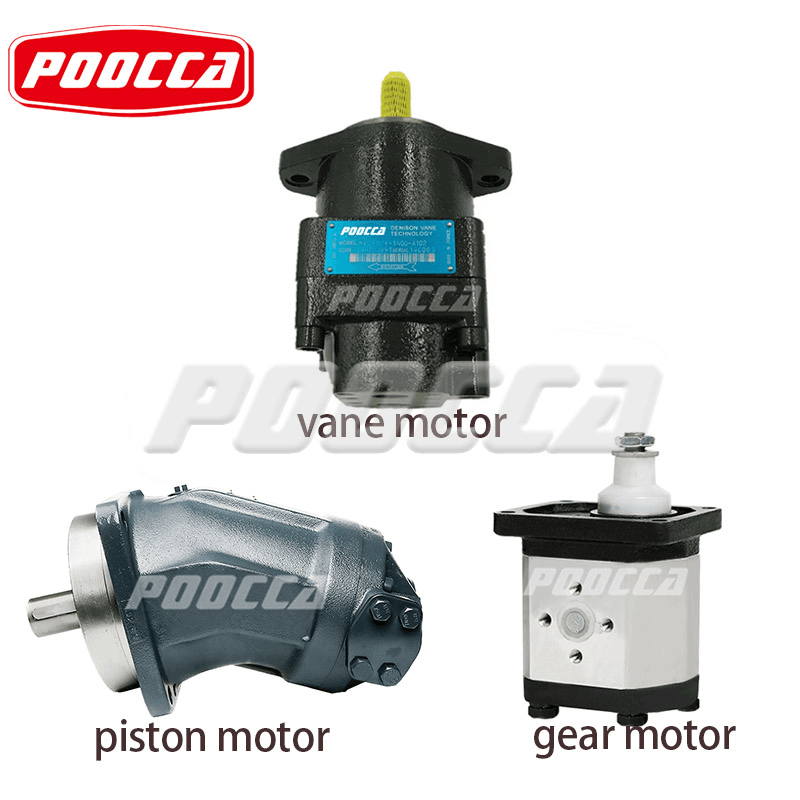

Looking For A Reliable Hydraulic Motors Manufacturer: POOCCA Is Ready To Help

Poocca液压(深圳)有限公司, started in 2006. They have factories in Guangdong, Jiangsu, and Zhejiang. They make full hydraulic systems, including pumps, valves, gearboxes, and motors. With over 26 years of know-how, they serve clients in over 100 countries. They work with brands like Rexroth, Danfoss, and Parker. POOCCA uses advanced CNC machines for quality. Whether you need bent axis or axial piston hydraulic motors, their team of over 300 experts helps from picking the right one to after-sales support. 立即与他们联系 for fast, trusty service worldwide.