Exploring the Fundamentals of Piston Pumps

Overview of Piston Pumps

Piston pumps play a vital role in many industrial and hydraulic applications due to their efficiency and versatility. These pumps operate by using a piston to displace fluid, creating consistent pressure suitable for various tasks. They can be single-acting or double-acting, depending on the application. Understanding the mechanics of piston pumps is crucial for industries that rely on precise fluid control, ensuring operations run smoothly and efficiently.

Common Applications

Piston pumps are employed in a wide array of applications. In the automotive industry, they are essential for fuel injection systems, while in agriculture, they drive irrigation systems. Aerospace applications rely on piston pumps for hydraulic actuation systems. Other prominent uses include manufacturing processes, construction equipment, and even medical devices, where the precise movement and control of fluids are critical. This widespread use highlights the importance of recognizing and mitigating any issues that can arise, such as noise.

Importance of Noise Management

Noise management is crucial in maintaining the efficiency and longevity of piston pumps. Excessive noise not only disrupts work environments but also indicates potential mechanical issues that could lead to costly repairs or shutdowns. By identifying and addressing noise sources early, companies can prevent wear and tear, enhance pump performance, and ensure a safer, more comfortable workspace. Thus, effective noise management isn’t just about comfort—it’s about operational efficiency and safety.

Identifying Common Noise Sources

Mechanical Vibration and Wear

Piston pumps are prone to mechanical vibration and wear, which can generate considerable noise. These vibrations result from the moving parts like pistons and valves that create friction and, over time, lead to wear. The wear process manifests as audible clanking or grinding sounds, signaling that components may be degrading and need attention.

Hydraulic Factors

Hydraulic factors also contribute significantly to piston pump noise. Fluid dynamics within the pump can cause turbulence and cavitation—phenomena where vapor bubbles form and implode within the fluid stream. These occurrences produce noise and potentially damage the pump’s internal surfaces. Pressure variations within the system create additional noise, as abrupt changes can lead to surges or spikes that reverberate through the pump housing.

Acoustic Emission

Acoustic emission refers to the sound waves generated by the mechanical actions within the piston pump. These sounds can be either structural, originating from the pump’s own components, or airborne, traveling through the medium surrounding the pump. Monitoring these emissions helps in pinpointing the exact sources of noise and formulating effective strategies for reduction.

Analysis of Mechanical Vibration and Wear

Causes of Mechanical Vibration

Imbalance in Components

Imbalance in the pump components is a primary cause of mechanical vibration. When the piston or other moving parts are not properly balanced, it creates uneven forces that lead to vibration. This imbalance can stem from manufacturing defects or wear and tear over time, causing the pump to operate less smoothly and generate noise.

Misalignment Issues

Misalignment issues occur when the piston or other components are not correctly aligned within the pump assembly. This misalignment disrupts the smooth operation of the pump, causing components to clash and generate noise. Regular maintenance and precise assembly are crucial in preventing misalignment and the subsequent noise issues it can create.

Effects on Pump Performance

Reduced Efficiency

Mechanical vibration can significantly reduce the efficiency of a piston pump. When components are vibrating excessively, the energy that should be used for pumping fluid is instead dissipated as sound and heat. This inefficiency necessitates higher energy consumption to achieve the same output, leading to increased operational costs.

Increased Wear and Tear

Prolonged mechanical vibration accelerates wear and tear on the pump components. Parts that are constantly vibrating are more likely to develop cracks, fatigue, and other forms of damage. This degradation compromises the pump’s longevity and reliability, resulting in more frequent maintenance and replacements—impacts that underline the importance of addressing noise issues promptly.

Hydraulic Factors Contributing to Noise

Fluid Flow Dynamics

Turbulence within the System

Turbulence within the fluid flow of a piston pump is a significant noise-generating factor. As fluid moves through the pump, it can encounter obstacles or sharp changes in direction that create chaotic fluid motion, known as turbulence. This random motion results in pressure fluctuations, which are perceived as noise. To mitigate this, pump designs often aim to streamline fluid paths and reduce abrupt changes in flow direction, minimizing turbulence and associated noise.

Cavitation Effects

Cavitation occurs when local pressure drops below the vapor pressure of the fluid, leading to the formation of vapor bubbles. These bubbles subsequently collapse violently as they move to higher-pressure zones, generating noise and shock waves. Cavitation not only contributes to noise but also causes significant damage to internal pump surfaces, exacerbating wear and reducing efficiency. Addressing cavitation involves careful management of pressure levels within the pump to prevent bubble formation.

Impact of Pressure Variations

Pressure variations within a piston pump system can be a major source of noise. Abrupt changes in pressure can create surges or spikes that cause vibrations and resultant noise. These pressure fluctuations can be due to operational factors such as load changes or valve operations. Implementing pressure stabilization techniques, such as accumulator use or pressure control valves, can help in maintaining a more consistent pressure profile and thus reduce noise levels.

Understanding Acoustic Emission in Piston Pumps

Types of Acoustic Emissions

Structural Noise

Structural noise is generated by the vibrations and mechanical interactions of the pump’s internal components. This type of noise can be transmitted through the pump housing and into the surrounding structures, creating a challenging noise issue to manage. Designing pumps with robust structural integrity and incorporating damping materials can help in absorbing these vibrations and reducing structural noise.

Airborne Noise

Airborne noise is the sound that emanates from the pump and travels through the air to the surrounding environment. It often results from both the fluid flow dynamics and mechanical operations within the pump. Effective strategies to reduce airborne noise include enclosing the pump in sound-absorbing materials and utilizing mufflers or silencers to dampen the emitted sound waves.

Measurement Techniques

Measuring acoustic emissions is critical for diagnosing and addressing noise issues in piston pumps. Techniques such as using microphones and accelerometers help in capturing a detailed noise profile of the pump. Analyzing this data enables professionals to identify specific noise sources and their intensities. Advanced diagnostic tools can also correlate noise patterns with operational parameters, providing insights for targeted noise reduction efforts.

Strategies for Reducing Piston Pump Noise

Design Improvements

Enhancing Component Balance

Improving the balance of moving components within the pump is a highly effective strategy for noise reduction. Precision engineering to ensure that pistons, valves, and other parts are accurately balanced minimizes the forces that cause vibration. Advanced computer-aided design (CAD) tools play a crucial role in achieving the optimal balance, significantly reducing mechanical noise.

Advanced Materials Use

The use of advanced materials in pump construction can greatly impact noise levels. Materials with higher damping properties can absorb more vibrational energy, thereby decreasing noise emissions. Innovative materials, such as composites and specialized alloys, not only enhance durability but also contribute to quieter pump operation.

Maintenance Practices

Regular Lubrication

Regular lubrication of moving parts is essential to minimize friction, one of the primary sources of noise. A well-lubricated pump operates more smoothly, with reduced wear on components, leading to quieter operation. Establishing a routine lubrication schedule ensures that the pump remains in optimal working condition, thus preventing excessive noise.

Replacement Schedules

Adhering to a stringent replacement schedule for worn-out parts can also help in noise reduction. Replacing degraded components before they fail prevents the increased vibrations and noises associated with worn parts. By proactively replacing parts, the overall integrity and performance of the piston pump are maintained, contributing to a quieter and more efficient operation.

Implementing Advanced Technologies for Noise Reduction

Active Noise Control Systems

Active noise control systems use advanced technology to cancel out noise emissions. These systems detect the noise frequency and generate an inverse sound wave to neutralize it, effectively reducing noise levels. Active noise control can be particularly effective in high-noise environments, providing a sophisticated solution for maintaining quieter pump operation.

Passive Damping Techniques

Passive damping techniques involve using materials and structural modifications to absorb vibrations and reduce noise. Examples include adding rubber mounts, sound-absorbing coatings, and vibration isolators. These methods are often integrated into the pump’s design and installation process, offering a cost-effective and efficient means of mitigating noise without the need for complex electronic systems.

Conclusion: Achieving Quieter Operation in Piston Pumps

Reducing noise in piston pumps is essential for enhancing their efficiency, longevity, and operational comfort. By understanding the various noise sources such as mechanical vibration, hydraulic factors, and acoustic emissions, industries can implement targeted solutions. Strategies including design improvements, regular maintenance practices, and the use of advanced noise reduction technologies can significantly diminish noise levels. Achieving quieter operation not only improves workplace conditions but also ensures that the pumps function efficiently and reliably, ultimately leading to improved productivity and cost savings.

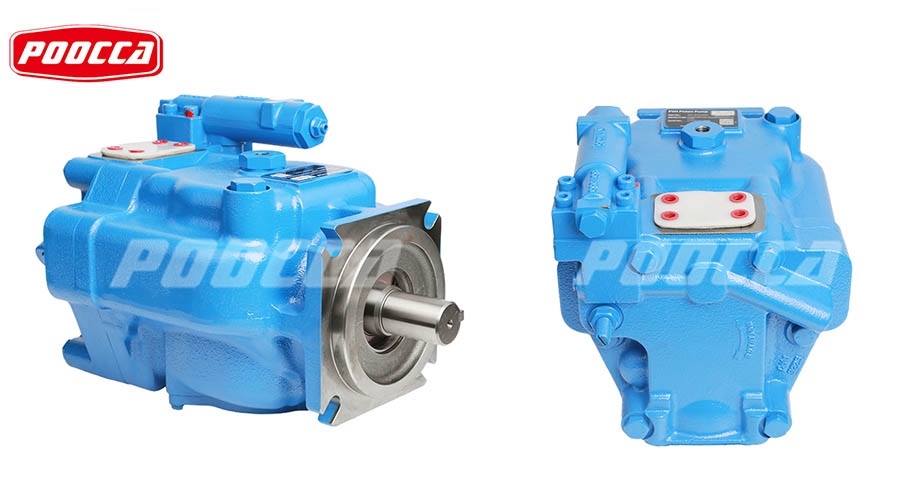

POOCCA offers a range of hydraulic products, including piston pumps. One of our popular products in this category is the Eaton Vickers PVH Piston Pump. This high-performance pump is available in various sizes and offers a geometric displacement of up to 141.1 cm3/r. It is designed for versatile applications and can operate at a rated pressure of 250 bar (230 bar for some models). The Eaton Vickers PVH Piston Pump features a compact and heavy-duty construction, ensuring superior performance and reliability. Although the specific applications are not mentioned in the provided content, this piston pump is known for its high operating performance and is widely used in hydraulic systems.