Overview of Hydraulic Cylinders

What Exactly is Hydraulic Cylinders?

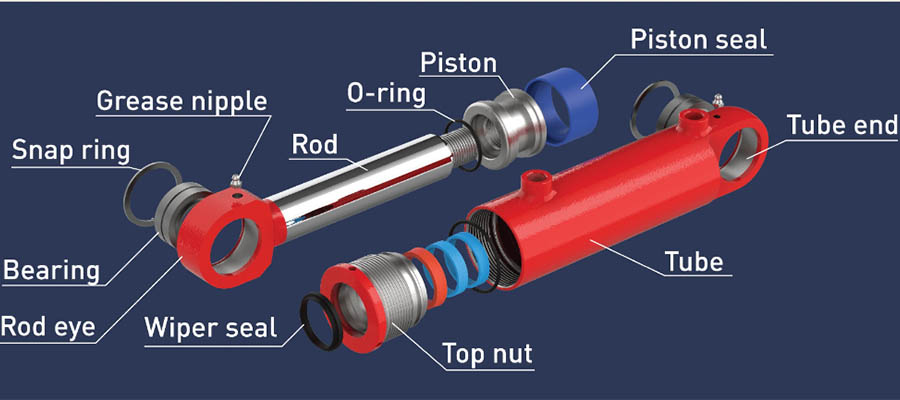

Hydraulic cylinders are crucial components in various industrial and mechanical systems. These devices convert fluid power into mechanical power, providing the force necessary to move or lift loads. Essentially, hydraulic cylinders operate on the principles of fluid dynamics, where pressurized fluid acts on a piston to generate movement. This ability to create powerful, controlled motion makes them indispensable in industries like construction, manufacturing, and automotive engineering.The most popular hydraulic cylinders is single-acting and double-acting cylinders.

Detailed Comparison: Single-Acting vs Double-Acting Hydraulic Cylinders

Mechanism and Operation

How Single-Acting Cylinders Work

Single-acting hydraulic cylinders are designed to exert force in a single direction. The cylinder contains a piston and rod, with hydraulic fluid introduced only on one side of the piston. When fluid pressure is applied, the piston moves, generating mechanical force. The piston retracts using an external force, often a spring or gravitational pull, allowing the cylinder to reset for another operation. This makes single-acting cylinders ideal for applications like vertical lifting where gravity can assist in retraction.

How Double-Acting Cylinders Work

In contrast, double-acting hydraulic cylinders utilize hydraulic fluid to move the piston in both directions. The cylinder has two ports for fluid entry and exit: one for extending the piston and another for retracting it. This dual-action capability allows for greater control and precision in movement, making double-acting cylinders suitable for applications requiring complex tasks like pushing and pulling. Examples include robotic arms, automated machinery, and other systems where multidirectional force is necessary.

Applications and Use Cases

Common Uses for Single-Acting Cylinders

Single-acting hydraulic cylinders are commonly used in scenarios where force is needed in only one direction, and where an external force can aid in retracting the piston. These cylinders find applications in simple mechanical setups such as car jacks, where the piston needs to lift and hold a load temporarily. Additionally, they are utilized in lifting platforms and hydraulic presses where a return spring can reset the piston without requiring additional hydraulic power.

Common Uses for Double-Acting Cylinders

Double-acting hydraulic cylinders, with their ability to exert force in both directions, are vital in more complex and varied tasks. They are extensively used in industrial machinery, such as in factory automation settings where precision and control are paramount. These cylinders are also prevalent in heavy-duty applications like earth-moving equipment, agricultural machinery, and in the manufacturing of tools that require precise, bidirectional force. Their versatility and control capabilities make them indispensable in settings that demand rigorous mechanical performance.

Advantages and Disadvantages

Pros and Cons of Single-Acting Cylinders

Single-acting hydraulic cylinders come with several advantages. Firstly, their simpler design means they are typically more cost-effective and easier to install. The reliance on fewer components can lead to increased reliability and less frequent need for maintenance. They also require fewer hydraulic connections, which reduces risks of leaks and other potential issues. However, the primary limitation of single-acting cylinders is their unidirectional force application, making them unsuitable for tasks requiring controlled movement in both directions. Additionally, the reliance on external forces for piston retraction can sometimes lead to slower reset speeds.

Pros and Cons of Double-Acting Cylinders

Double-acting cylinders offer the significant advantage of providing controlled, powerful motion in both directions, which enhances versatility and functionality in various applications. This bidirectional control allows for precise movements and greater flexibility in industrial tasks. The primary disadvantage, however, lies in their complexity: double-acting cylinders are generally more expensive and require more hydraulic connections, which may increase the risk of hydraulic leaks and require more rigorous maintenance. The need for more components also means that installation and troubleshooting can be more complex compared to single-acting cylinders.

Maintenance Requirements

Maintaining Single-Acting Cylinders

Maintaining single-acting hydraulic cylinders tends to be straightforward. Regular checks should include inspecting for hydraulic fluid leaks and ensuring that the seals are intact. The external force mechanism, whether it be a spring or gravity-assisted mechanism, should also be inspected to confirm it operates correctly. Lubrication of the piston rod is essential to prevent wear and tear from friction. Given their simpler design, single-acting cylinders usually experience fewer points of potential failure, making their routine maintenance less intensive compared to double-acting cylinders.

Maintaining Double-Acting Cylinders

Double-acting hydraulic cylinders require a more detailed maintenance regimen due to their complexity and the need for fluid to act on both sides of the piston. Regular inspections should include checking the integrity of both hydraulic fluid connections and monitoring for leaks on both sides of the piston. Seals on either end need to be inspected rigorously to prevent contamination and ensure optimal performance. Since these cylinders are subject to higher operational demands, it’s also crucial to monitor the condition of internal components, such as the piston and cylinder bore, to catch signs of wear early. Regular lubrication and timely replacement of worn parts are essential to maintaining their operational efficiency.

Factors to Consider When Choosing Between the Two

Application Needs

The choice between single-acting and double-acting hydraulic cylinders depends largely on the specific requirements of the application. For tasks that only require force in one direction, such as lifting or clamping, single-acting cylinders may be sufficient and more cost-effective. Conversely, if the application requires precise control of movement in both directions, a double-acting cylinder would be more appropriate. Understanding the scope and nature of the task is critical in making the right selection.

Cost Implications

Cost is a significant factor when choosing between single-acting and double-acting hydraulic cylinders. Single-acting cylinders typically involve lower initial costs due to their simpler design and fewer components, which also translates into reduced maintenance expenses. On the other hand, double-acting cylinders, although more expensive, offer higher functionality and efficiency for complex tasks. The investment in double-acting cylinders can be justified in scenarios where their bidirectional capabilities can enhance productivity and performance, ultimately leading to long-term cost savings.

Reliability and Efficiency

Reliability and operational efficiency are crucial considerations in selecting hydraulic cylinders. Single-acting cylinders often have fewer failure points due to their simpler mechanism, making them reliable for straightforward, repetitive tasks. Double-acting cylinders offer greater efficiency in terms of speed and precision of movement, which can be vital in dynamic industrial environments. Evaluating the operational demands and the importance of reliability and efficiency in your specific context will guide you towards the most suitable choice.

Conclusion: Making an Informed Choice

When selecting between single-acting and double-acting hydraulic cylinders, it is essential to thoroughly analyze your operational needs, budget constraints, and maintenance capabilities. Single-acting cylinders may offer advantages in terms of cost and simplicity, making them ideal for simpler tasks with unidirectional force requirements. Double-acting cylinders, though more complex and costly, provide superior control and versatility for more demanding applications. By carefully weighing these factors, you can make an informed decision that aligns with your specific needs and operational goals, ensuring optimal performance and efficiency in your hydraulic systems.

POOCCA offers a wide range of hydraulic products, including gear pumps, piston pumps, vane pumps, motors, hydraulic accessories, hydraulic valves, and hydraulic cylinders. One of our popular products is the POOCCA Hydraulic Cylinder. These cylinders are designed to provide reliable and efficient hydraulic power for various applications. They are built with high-quality materials and precision engineering to ensure durability and long-lasting performance. The POOCCA Hydraulic Cylinders come in different sizes and configurations to meet the specific needs of different industries. They are widely used in construction machinery, agricultural equipment, industrial machinery, and more. With their excellent performance and reliability, POOCCA Hydraulic Cylinders are trusted by professionals worldwide.