Menu

Close

Menu

Close

[gtranslate]

The 03Z50-AAA-ES3-12VDC-G is a three-section solenoid directional valve in monoblock form, built for robust control of multiple hydraulic circuits in compact space. Each spool (section) is individually actuated by a solenoid, allowing independent control of up to three hydraulic actuators (cylinders or motors) in one integrated unit.

In its neutral position, the open-center “A” spool design allows internal flow paths (as per standard open center logic), facilitating a balanced circuit bypass. When a solenoid is energized, the respective spool shifts, routing pressure fluid and returning flow as designed.

This valve is suitable for systems requiring reliable switching under high pressures and moderate flow rates. Its compact design, strong pressure capability, and modularity (3 spools) make it ideal for applications such as agricultural equipment, hydraulic trailers, lift systems, material handling, and similar machinery.

Solenoid-operated directional control valve (on/off) in monoblock construction (all spools in single body)

3 working sections (spools) in one unit, enabling control of three hydraulic actuators independently

Standard spool configuration: Open center “A” spool with spring return (neutral)

Coil voltage: 12 V DC

Nominal flow rate: 50 L/min (≈13 GPM)

Maximum pressures: P port up to ~315 bar, A/B up to ~300 bar, T port up to ~50 bar

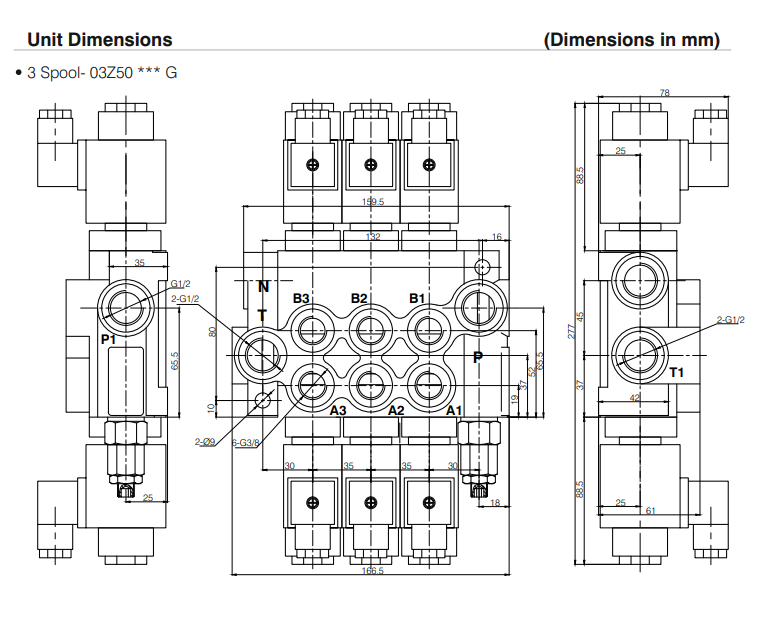

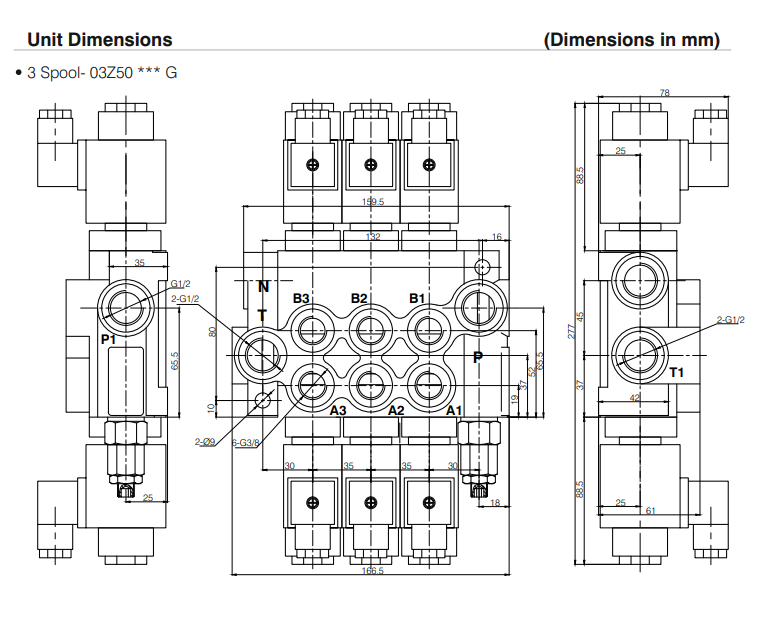

Port threads:

• P, T ports: G 1/2″ (BSPP)

• A, B ports: G 3/8″ (BSPP)

Low internal leakage (neutral): ≤ ~18 cm³/min (A/B → T) at 100 bar (typical for Z50 series)

Operating fluid: mineral-based hydraulic oil

Viscosity range: ~10–100 cSt; typical recommendation ~46 cSt

Operating temperature: –10 °C to +80 °C (or similar range depending on manufacturer)

Filtration requirement: typically 10 µm (or meet NAS 1638 class)

Designed for mobile and industrial hydraulic systems (e.g. cylinders, motors)

| Parameter | Value / Range |

|---|---|

| Model | 03Z50-AAA-ES3-12VDC-G |

| Series | Z50 |

| Number of Spools | 3 |

| Spool Type (Neutral) | Open center “A” spool with spring return |

| Coil Voltage | 12 V DC |

| Nominal Flow Rate | 50 L/min (approx. 13 GPM) |

| Max Pressure (P port) | ~ 315 bar |

| Max Pressure (A, B ports) | ~ 300 bar |

| Max Pressure (T port) | ~ 50 bar |

| Port Threads | P/T: G 1/2″ (BSPP) • A/B: G 3/8″ (BSPP) |

| Internal Leakage (neutral) | ≤ ~18 cm³/min (A/B → T at 100 bar) |

| Fluid Type | Mineral-based hydraulic oil |

| Viscosity Range | 10 – 100 cSt |

| Operating Temperature | –10 °C to +80 °C (or per manufacturer) |

| Filtration Grade | ~10 µm (NAS standard) |

Poocaa has focused on the hydraulic / control valve industry for years, striving to master core technologies in solenoid control, spool finishing, sealing systems, and fluid dynamics. This specialized focus enables us to design and manufacture high-performance valves (such as the 03Z50 series) with reliability and precision.

We operate modern CNC machining, precision grinding, and automated assembly lines to maintain tight tolerances and consistent quality.

Each valve undergoes rigorous inspection: dimensional checks, leak testing, spool movement tests, pressure endurance, and electric coil testing.

ISO / quality management systems (e.g. ISO 9001) (if applicable) ensure that from raw materials to finished goods, all processes are documented, tracked, and controlled.

We maintain an in-house R&D / engineering team capable of customizing spool types, control logics (open center, closed center, float, etc.), coil voltage variants, and port configurations to meet unique client demands.

We continuously improve seal materials, minimize internal leakage, optimize flow paths, and reduce response times.

We support prototyping, small-batch production, and design verification services so customers can test before full deployment.

The Poocaa valve portfolio spans multiple series (monoblock, sectional, cartridge, etc.), voltage options (12 V, 24 V, AC, etc.), and spool types.

Modular design allows combining sections (spools) to achieve multi-circuit control with flexibility and reduced inventory complexity.

Because of standardized modular interfaces, upgrading or replacing sections is easier and cost-effective.

We maintain close relationships with upstream suppliers (steel, seals, electronics) to optimize cost and lead time.

Lean manufacturing and waste reduction initiatives help us offer competitive pricing without compromising quality.

With warehouses or distribution networks in key regions, we can ensure timely delivery and reduce logistics bottlenecks for customers.

Valves are tested for long service life, with stress tests over many cycles to ensure stability under repeated use.

We provide warranty support, spare parts, seal kits, and technical assistance to help our customers maintain and repair equipment with minimal downtime.

Our team can assist in troubleshooting, installation guidelines, and system integration advice.

We view each client as unique: for demanding projects, we offer customization—spool types, mounting patterns, control logic, voltage, etc.

We provide technical consultation during system design stages to help clients choose the right valve model for performance, cost, and reliability balance.

We accept small/medium orders as well as large volume orders—flexibility in MOQ / lot sizes.

Our products can meet relevant industrial standards and (if your market requires) certifications for safety, materials, electrical insulation, pressure rating, etc.

We adhere to environmental, RoHS, REACH, and other regulatory requirements depending on region, enabling international sales without compliance issues.

Over years of operation, Poocaa has built a track record of successful projects, stable deliveries, and satisfied customers (you can cite case studies or client lists).

Transparency in production, clear documentation (datasheets, QC reports), and post-sale responsiveness help build customer confidence.

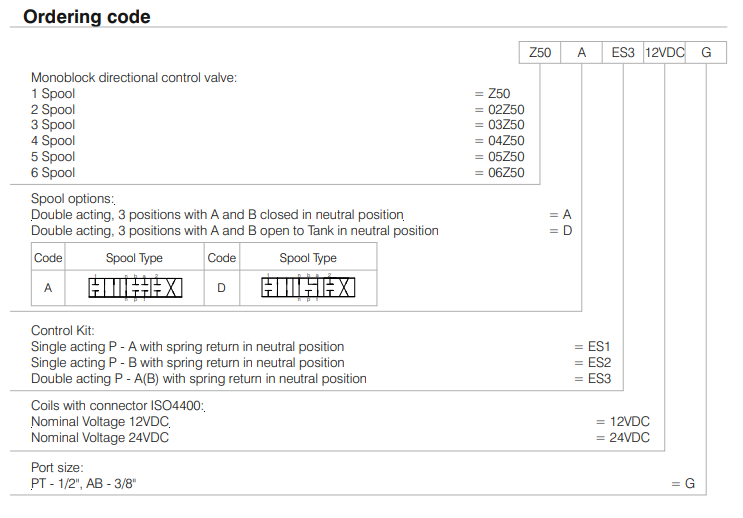

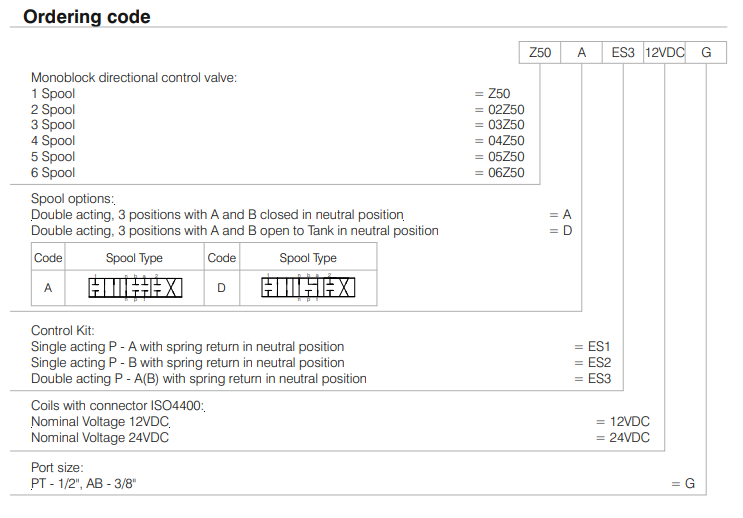

Q1: What does “ES3” mean in the 03Z50-AAA-ES3-12VDC-G model?

“ES3” indicates a double-acting solenoid with spring return to neutral. That means when the coil is de-energized, the spool is forced back to the neutral (center) position by springs.

Q2: What is the maximum pressure and flow capacity of this valve?

This valve is part of the Z50 series, which supports up to 315 bar at the P port, about 300 bar at A/B ports, and 50 bar at the T port. Its nominal flow is 50 L/min.

Q3: What hydraulic fluid and viscosity range should be used?

Use mineral-based hydraulic oil. The recommended viscosity range is about 10–100 cSt (typical ~46 cSt).

If you use different seal materials (e.g. Viton), the permissible temperatures and fluid ranges may vary.

Q4: What is the internal leakage in neutral?

At Δp = 100 bar, leakage from A or B to T is generally ≤ 18 cm³/min for the Z50 series.

Q5: What are the thread sizes of the ports?

Port P and T: G 1/2″ (BSPP)

Ports A and B: G 3/8″ (BSPP)

Q6: Is there a 24 V version available?

Yes. The Z50 series supports both 12 V DC and 24 V DC coils. You should specify which version when ordering.

The 03Z50-AAA-ES3-12VDC-G is a three-section solenoid directional valve in monoblock form, built for robust control of multiple hydraulic circuits in compact space. Each spool (section) is individually actuated by a solenoid, allowing independent control of up to three hydraulic actuators (cylinders or motors) in one integrated unit.

In its neutral position, the open-center “A” spool design allows internal flow paths (as per standard open center logic), facilitating a balanced circuit bypass. When a solenoid is energized, the respective spool shifts, routing pressure fluid and returning flow as designed.

This valve is suitable for systems requiring reliable switching under high pressures and moderate flow rates. Its compact design, strong pressure capability, and modularity (3 spools) make it ideal for applications such as agricultural equipment, hydraulic trailers, lift systems, material handling, and similar machinery.

Solenoid-operated directional control valve (on/off) in monoblock construction (all spools in single body)

3 working sections (spools) in one unit, enabling control of three hydraulic actuators independently

Standard spool configuration: Open center “A” spool with spring return (neutral)

Coil voltage: 12 V DC

Nominal flow rate: 50 L/min (≈13 GPM)

Maximum pressures: P port up to ~315 bar, A/B up to ~300 bar, T port up to ~50 bar

Port threads:

• P, T ports: G 1/2″ (BSPP)

• A, B ports: G 3/8″ (BSPP)

Low internal leakage (neutral): ≤ ~18 cm³/min (A/B → T) at 100 bar (typical for Z50 series)

Operating fluid: mineral-based hydraulic oil

Viscosity range: ~10–100 cSt; typical recommendation ~46 cSt

Operating temperature: –10 °C to +80 °C (or similar range depending on manufacturer)

Filtration requirement: typically 10 µm (or meet NAS 1638 class)

Designed for mobile and industrial hydraulic systems (e.g. cylinders, motors)

| Parameter | Value / Range |

|---|---|

| Model | 03Z50-AAA-ES3-12VDC-G |

| Series | Z50 |

| Number of Spools | 3 |

| Spool Type (Neutral) | Open center “A” spool with spring return |

| Coil Voltage | 12 V DC |

| Nominal Flow Rate | 50 L/min (approx. 13 GPM) |

| Max Pressure (P port) | ~ 315 bar |

| Max Pressure (A, B ports) | ~ 300 bar |

| Max Pressure (T port) | ~ 50 bar |

| Port Threads | P/T: G 1/2″ (BSPP) • A/B: G 3/8″ (BSPP) |

| Internal Leakage (neutral) | ≤ ~18 cm³/min (A/B → T at 100 bar) |

| Fluid Type | Mineral-based hydraulic oil |

| Viscosity Range | 10 – 100 cSt |

| Operating Temperature | –10 °C to +80 °C (or per manufacturer) |

| Filtration Grade | ~10 µm (NAS standard) |

Poocaa has focused on the hydraulic / control valve industry for years, striving to master core technologies in solenoid control, spool finishing, sealing systems, and fluid dynamics. This specialized focus enables us to design and manufacture high-performance valves (such as the 03Z50 series) with reliability and precision.

We operate modern CNC machining, precision grinding, and automated assembly lines to maintain tight tolerances and consistent quality.

Each valve undergoes rigorous inspection: dimensional checks, leak testing, spool movement tests, pressure endurance, and electric coil testing.

ISO / quality management systems (e.g. ISO 9001) (if applicable) ensure that from raw materials to finished goods, all processes are documented, tracked, and controlled.

We maintain an in-house R&D / engineering team capable of customizing spool types, control logics (open center, closed center, float, etc.), coil voltage variants, and port configurations to meet unique client demands.

We continuously improve seal materials, minimize internal leakage, optimize flow paths, and reduce response times.

We support prototyping, small-batch production, and design verification services so customers can test before full deployment.

The Poocaa valve portfolio spans multiple series (monoblock, sectional, cartridge, etc.), voltage options (12 V, 24 V, AC, etc.), and spool types.

Modular design allows combining sections (spools) to achieve multi-circuit control with flexibility and reduced inventory complexity.

Because of standardized modular interfaces, upgrading or replacing sections is easier and cost-effective.

We maintain close relationships with upstream suppliers (steel, seals, electronics) to optimize cost and lead time.

Lean manufacturing and waste reduction initiatives help us offer competitive pricing without compromising quality.

With warehouses or distribution networks in key regions, we can ensure timely delivery and reduce logistics bottlenecks for customers.

Valves are tested for long service life, with stress tests over many cycles to ensure stability under repeated use.

We provide warranty support, spare parts, seal kits, and technical assistance to help our customers maintain and repair equipment with minimal downtime.

Our team can assist in troubleshooting, installation guidelines, and system integration advice.

We view each client as unique: for demanding projects, we offer customization—spool types, mounting patterns, control logic, voltage, etc.

We provide technical consultation during system design stages to help clients choose the right valve model for performance, cost, and reliability balance.

We accept small/medium orders as well as large volume orders—flexibility in MOQ / lot sizes.

Our products can meet relevant industrial standards and (if your market requires) certifications for safety, materials, electrical insulation, pressure rating, etc.

We adhere to environmental, RoHS, REACH, and other regulatory requirements depending on region, enabling international sales without compliance issues.

Over years of operation, Poocaa has built a track record of successful projects, stable deliveries, and satisfied customers (you can cite case studies or client lists).

Transparency in production, clear documentation (datasheets, QC reports), and post-sale responsiveness help build customer confidence.

Q1: What does “ES3” mean in the 03Z50-AAA-ES3-12VDC-G model?

“ES3” indicates a double-acting solenoid with spring return to neutral. That means when the coil is de-energized, the spool is forced back to the neutral (center) position by springs.

Q2: What is the maximum pressure and flow capacity of this valve?

This valve is part of the Z50 series, which supports up to 315 bar at the P port, about 300 bar at A/B ports, and 50 bar at the T port. Its nominal flow is 50 L/min.

Q3: What hydraulic fluid and viscosity range should be used?

Use mineral-based hydraulic oil. The recommended viscosity range is about 10–100 cSt (typical ~46 cSt).

If you use different seal materials (e.g. Viton), the permissible temperatures and fluid ranges may vary.

Q4: What is the internal leakage in neutral?

At Δp = 100 bar, leakage from A or B to T is generally ≤ 18 cm³/min for the Z50 series.

Q5: What are the thread sizes of the ports?

Port P and T: G 1/2″ (BSPP)

Ports A and B: G 3/8″ (BSPP)

Q6: Is there a 24 V version available?

Yes. The Z50 series supports both 12 V DC and 24 V DC coils. You should specify which version when ordering.

POOCCA Hydraulics is a powerful hydraulic enterprise integrating R&D, manufacturing, sales and maintenance. Its products are exported to more than 120 countries. Its quality, price and service are deeply recognized and trusted by customers.

Welcome to contact us using WeChat

Welcome to contact us via whatsapp