Hydraulic systems are vital for many machines. They need to work well, save energy, and adapt to different tasks. Among all the parts in these systems, the variable displacement piston pump is a star. It’s a powerful tool that changes how industries operate. It saves energy, gives exact control, and handles different workloads. Whether you use big factory machines, construction tools, or boats, this pump can make your hydraulic system better. It also cuts costs. In this article, we’ll explain why this variable displacement piston pump is so important. We’ll talk about its benefits, uses, and how to pick and care for one that fits your needs.

Introduction to Variable Displacement Piston Pumps

Hydraulic systems power many industries. They run everything from giant machines to precise tools. The pump is the heart of these systems. The variable displacement piston pump is a top choice in modern technology. Unlike older fixed displacement pumps, this pump can change its flow and pressure as needed. This makes it great for tasks that need energy savings and accuracy.

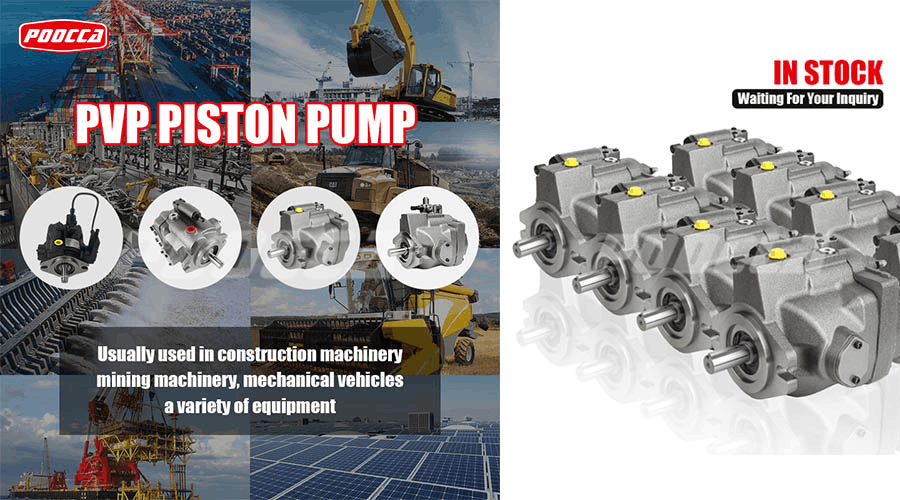

Manufacturer like POOCCA make reliable hydraulic solutions. They create strong variable displacement piston pumps built to last. POOCCA’s pumps help industries worldwide. They solve tough hydraulic problems with smart designs.

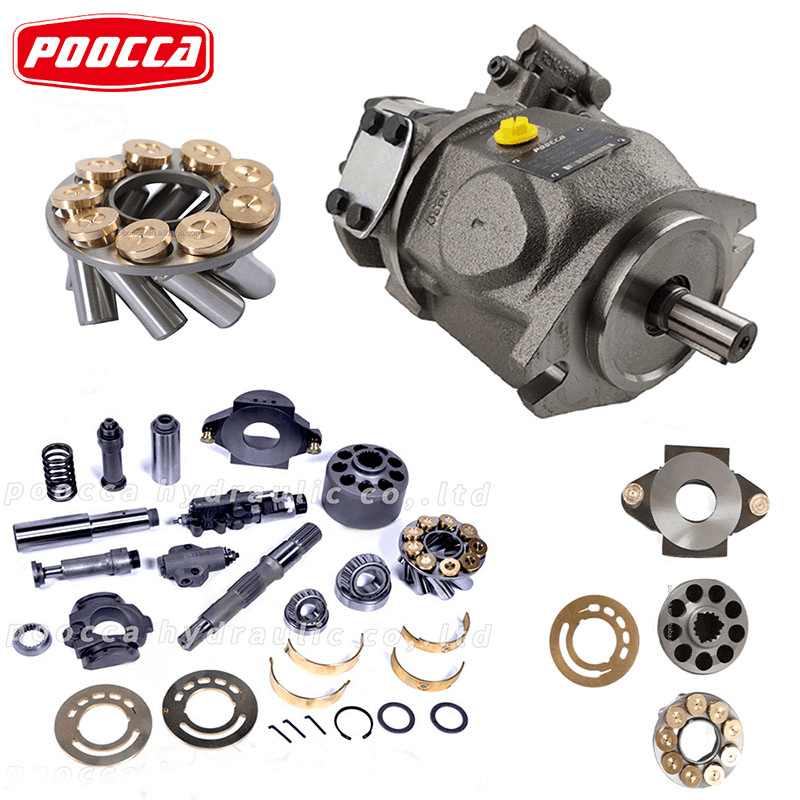

Main Components of a Variable Displacement Piston Pump

To see why these pumps are great, let’s look at their main parts:

- Pistons: These sit in a circle inside a cylinder block. They push the fluid to make it flow.

- Swashplate: This part can tilt. It changes how far the pistons move, controlling the fluid amount.

- Inlet and Outlet Ports: These let hydraulic fluid come in and go out smoothly.

- Control Mechanisms: Smart features like load-sensing and pressure compensation make the pump work better.

These parts team up to adjust the fluid flow. This makes the pump flexible and useful for many jobs.

How a Variable Displacement Piston Pump Works

The pump’s magic lies in its swashplate. By tilting the swashplate, the pump changes how far the pistons move. This controls how much fluid comes out each time.

- Big Swashplate Tilt: The pistons move more. This sends out more fluid.

- Small Swashplate Tilt: The pistons move less. This lowers the fluid flow or stops it if needed.

- Smart Adjustments: The pump watches what the system needs. It changes instantly to save energy.

This setup gives exact control, cuts down on heat, and supports load-sensing. It’s perfect for jobs needing flexibility.

Key Benefits of Using Variable Displacement Pumps

These pumps bring many advantages. They’re a top pick for modern hydraulic systems. Here’s why:

- Saves Energy: The pump matches flow and pressure to the job. This cuts energy waste and lowers costs. For instance, POOCCA’s pumps are built to use energy wisely. They help businesses save money and be eco-friendly.

- Less Heat: The pump only works as hard as needed. This keeps the system cool and makes fluids and parts last longer.

- Small and Light: The pump’s smart design means systems can be smaller. This is great for mobile machines or tight spaces.

- Better Control: Features like load-sensing give precise control. This makes the system steady and strong.

- Saves Money Over Time: These pumps cost more at first than fixed pumps. But they save energy and maintenance costs, making them a smart choice.

These benefits make variable displacement pumps essential. They help industries work better and harm the environment less.

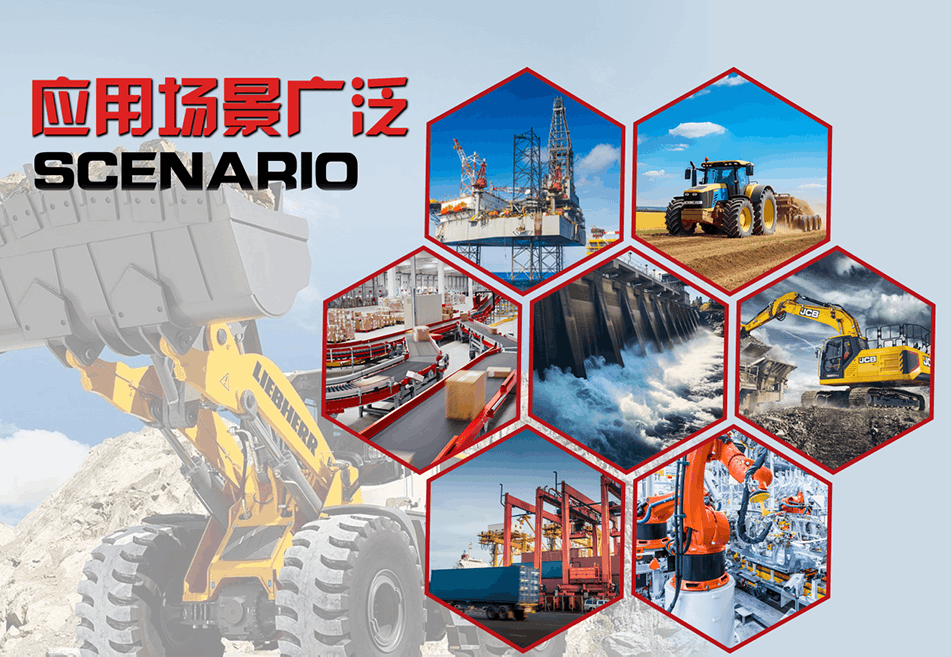

Applications Across Industries

Variable displacement piston pumps are super versatile. They work in many industries with different needs:

- Industrial Machinery: Factories use these pumps in presses and molding machines. They give exact control and high efficiency.

- Construction Equipment: Excavators, bulldozers, and backhoes need these pumps. They handle tough jobs with changing loads.

- Agricultural Equipment: Tractors and harvesters use these pumps. They adjust flow for different tasks, saving fuel.

- Marine Systems: Boats use these pumps for winches and steering. They work well in harsh sea conditions.

- Aerospace: Airplanes need precise, lightweight pumps for actuation systems. These pumps fit the bill.

POOCCA’s variable displacement piston pumps are built for these jobs. Check their catalog at kamchau.com. They offer steady performance and toughness.

Choosing the Right Variable Displacement Pump

Picking the best pump for your system takes thought. Here are key things to consider:

- Maximum Pressure: Make sure the pump can handle your system’s top pressure.

- Flow Rate Range: Check if the pump covers the flow rates your job needs.

- System Fit: See if your system needs load-sensing or pressure compensation features.

- Brand Trust: Pick a maker like POOCCA. They’re known for quality and great support. Their website shows they offer reliable pumps and spare parts.

- Work Environment: Think about where the pump will work. Harsh conditions like heat or cold affect durability.

By matching these to your system, you’ll get a pump that works great and lasts long.

Fixed vs. Variable Displacement Pumps

Let’s compare variable displacement pumps with fixed ones to show why they’re better:

| Feature | Fixed Displacement Pump | Variable Displacement Pump |

| Flow Rate | Always the same | Can change as needed |

| Efficiency | Not as good | Much better |

| Control | Basic | Smart (load-sensing, pressure-compensated) |

| Heat Generation | More heat | Less heat |

| Initial Cost | Cheaper | More expensive |

| Lifecycle Cost | Costs more over time | Saves money over time |

Variable displacement pumps are more efficient and flexible. They’re a smarter choice for systems that change a lot.

Maintenance Tips for Variable Displacement Pumps

To keep your pump running well for years, follow these tips:

- Check Often: Look for leaks, wear, or odd shakes. Catching problems early saves trouble.

- Manage Fluid: Keep hydraulic fluid clean and at the right level. Change it when the maker says.

- Replace Filters: Swap out filters on the maker’s schedule to keep fluid clean.

- Control Heat: Use cooling systems to stop overheating, especially in tough jobs.

- Use OEM Parts: Stick with original parts from POOCCA. They fit right and keep the pump reliable.

These steps help your pump last longer and work at its best.

Conclusion

Switching to a variable displacement piston pump is a smart move for any hydraulic system. It saves energy, gives precise control, and works in many industries. Whether you’re in construction, farming, or aerospace, a quality pump from POOCCA can improve your work. It cuts costs and boosts performance.

Check out POOCCA’s variable displacement piston pumps at kamchau.com/products. Find the right pump for your hydraulic system.

FAQs

Q1. What is the purpose of a variable displacement pump?

It adjusts fluid flow and pressure to match what the system needs. This saves energy and improves performance.

Q2. How does a variable displacement pump function?

It changes the swashplate angle to control piston movement. This adjusts how much fluid comes out.

Q3. What is the most widely used variable displacement pump?

Axial piston pumps are popular. They’re efficient and work in many industrial and mobile jobs.

Q4. How do variable displacement pumps adjust flow?

They tilt the swashplate to change the piston stroke. This controls the fluid volume per cycle.

Q5. Which types of pumps are variable displacement?

Axial piston pumps and bent axis piston pumps are the main types used in hydraulic systems.

Partner with a Trusted Hydraulic Pump Manufacturer

Want to make your hydraulic system better? POOCCA is a top hydraulic pump supplier. They offer a wide range of variable displacement piston pumps built for strength and accuracy. Visit kamchau.com to see their products. Reach out to their team for solutions that fit your needs. Contact them at sales@kamchau.com or browse their catalog at kamchau.com/products. Find the perfect pump for your industrial, construction, or farming needs. Team up with POOCCA to take your hydraulic systems to the next level!