Hydraulic radial piston motors are vital parts in big machines. They provide strong, slow-turning power for tasks in building, mining, and moving heavy items. Their special setup, with pistons placed in a star shape around a central shaft, gives steady strength without needing extra gears to slow things down. But these motors can break easily. The biggest problem is hydraulic contamination, which hurts their dependability.

What is Hydraulic Radial Piston Motors

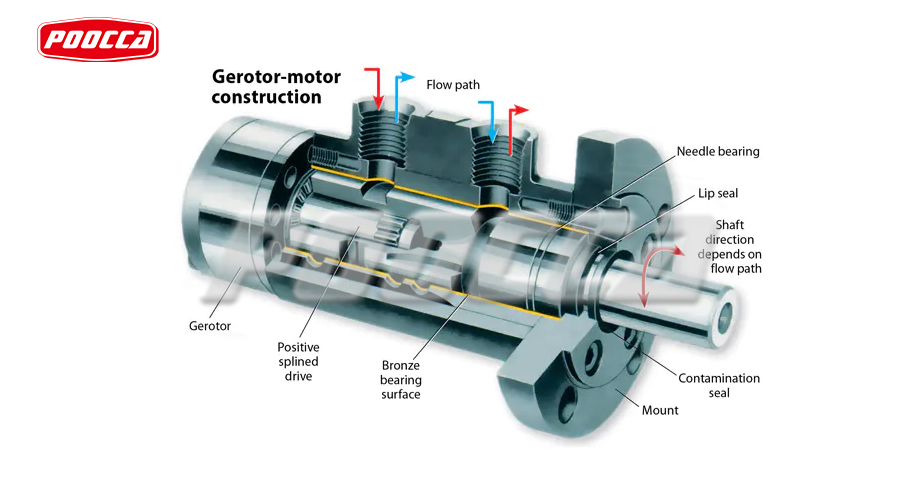

Hydraulic radial piston motors turn fluid pressure into spinning energy. They use a star-shaped piston setup. The pistons sit in a central block and push against a cam ring to make power. This power turns the shaft, which moves tracks, wheels, or other parts. Unlike other motors, hydraulic radial piston motors focus on strength, not speed. This makes them perfect for machines like track loaders, diggers, and winches.

The piston block is the core of the motor. It handles fluid flow to keep power smooth. Parts like distributor shafts, valve plates, and cam surfaces need careful upkeep. If these motors fail, they might move jerkily, lose strength, or stop completely. Knowing why they break helps find fixes.

Hydraulic Contamination: The Leading Cause of Failure

Hydraulic contamination is the top reason hydraulic radial piston motors break. It causes 75% to 90% of system failures. Contaminants are tiny bits, like metal scraps or sand (abrasive) or water and air (non-abrasive). These bits mix into the fluid and harm the motor. Abrasive bits scratch important surfaces like the piston block or cam ring. Water causes rust and weakens lubrication, leading to cavitation. Cavitation happens when tiny bubbles in the fluid collapse and damage metal parts.

Sources of Contamination

Contamination comes from different places:

- Manufacturing Leftovers: Sand from casting, weld bits, or sealant left from building the motor.

- Poor Maintenance: Dust or dirt gets in during fluid changes or part fixes.

- Wear Inside: Metal bits from rubbing parts create more damage over time.

- Broken Parts: Worn seals, damaged breathers, or scratched shafts let outside dirt sneak in.

These issues mess with the motor’s tight fit. They cause leaks inside and lower efficiency. Studies show contamination can cut a motor’s life by half. This proves clean fluid is critical.

Impact of Contamination

Abrasive bits scratch piston block surfaces, causing pits and wear. This lowers power. Water mixes with fluid, making it thin and rusty. Cavitation, worsened by contamination, creates tiny shocks that harm cam lobes and piston rollers. Signs of trouble include shaky motion, weak power on one side, or odd shaking. These signal a need to check fluid and filters fast.

Secondary Causes of Hydraulic Radial Piston Motor Failure

Overpressurization and Case Drain Issues

Too much pressure in the motor’s case drain system throws off piston-cam teamwork. Pistons may lose touch with the cam during the exhaust step. This causes wild spinning or odd motion, especially when loads stop suddenly. High case pressures—above 2 bar average or 10 bar peak—stress shaft seals. This leads to leaks and more contamination risks.

Sudden pressure jumps from quick load changes or small relief valves strain parts. They can bend plates or push piston slippers loose. Data shows 20-25% of hydraulic radial piston motor problems come from too much pressure. Fixing this needs direct drainage to the reservoir and pressure-balanced flow controls.

Cavitation-Induced Erosion

Cavitation happens even without contamination. Low inlet pressure or not enough fluid makes vapor bubbles. These bubbles burst and chip away at surfaces. In hydraulic radial piston motors, this hurts cam rings and piston rollers. It lowers power and causes uneven pressure. Inlet pressures below 10 bar absolute speed up damage, especially in machines like diggers that handle changing loads.

Thermal Overload and Fluid Degradation

Hot temperatures hurt hydraulic fluid. They make it thin and cause buildup of sticky varnish. In hydraulic radial piston motors, heat gathers where pistons meet the cam. This creates tiny cracks in the cam ring and jams pistons as they expand. Running above 80°C speeds up wear. Case drain temperatures over 115°C can ruin seals and stop the motor. Poor cooling, heavy work, or bad airflow often cause this.

Lubrication Deficiencies

Not enough lubrication, separate from contamination, comes from wrong fluid or worn-out additives. This leads to metal rubbing metal in high-friction spots. In hydraulic radial piston motors, low-speed, high-load work causes scratches on cam lobes and piston rollers. This increases leaks by up to 15%. Wear on the distributor shaft also cuts efficiency. You can spot this by shiny or uneven valve plate surfaces.

Mechanical Overload and Component Fatigue

Too much force or sudden shocks tire out motor parts. This starts tiny cracks in piston blocks or cam rings. In hydraulic radial piston motors, repeated heavy work—like in mining or lifting—misaligns pistons and stresses supports. Shaking from uneven shafts makes this worse, loosening parts and causing breaks. Logs show 10-15% of motor issues come from overload, often with odd noise or uneven power.

Seal and Component Wear

Old or badly set seals in hydraulic radial piston motors let fluid leak and air sneak in. This acts like contamination. Repeated pressure or wrong seal materials cause them to break or harden. Worn piston rings let fluid pass, cutting power. Checking torque during setup and using the right materials can make seals last over 5,000 hours.

Diagnostic and Preventive Strategies for Hydraulic Radial Piston Motors

To find problems, take the motor apart cleanly and measure part gaps carefully. Check fluid for dirt and metal bits. Look for scratches, pits, or cavitation marks to find the cause. Track pressure to spot overpressurization.

Ways to prevent issues include:

- Fluid Care: Use OEM-approved oils (ISO VG 32-68). Change them on time to keep them strong.

- Filtering: Use good filters (beta ratio >200). Watch pressure drops to catch dirt.

- Temperature Control: Add coolers and keep fluid below 115°C to avoid heat damage.

- Pressure Balance: Use pressure-adjusted pumps and direct drainage to steady case pressure.

- Load Control: Add torque limiters and vibration dampers to ease strain.

- System Cleaning: Flush systems after fixes to clear leftover dirt and reduce early wear.

These steps can make hydraulic radial piston motors last 40-50% longer. They improve dependability and save money.

FAQ

What is the primary cause of hydraulic radial piston motor failure? Hydraulic contamination causes 75-90% of failures. It brings in harmful bits that wear down key parts.

How does overpressurization affect hydraulic radial piston motors? It messes up piston-cam contact, causes seal leaks, and leads to wild motion, often from high case drain pressure.

What role does cavitation play in motor damage? Low inlet pressure makes bubbles that burst, chipping cam rings and pistons, which cuts power and efficiency.

Why is overheating detrimental to hydraulic radial piston motors? Hot temperatures ruin fluid, create sticky buildup, and tire parts, risking motor failure above 115°C.

How does insufficient lubrication impact motor performance? It causes scratches and leaks, lowering efficiency due to metal rubbing in high-friction areas.

What are signs of mechanical overload in hydraulic radial piston motors? Cracks, misalignment, or odd noises from too much force or shaking show fatigue damage.

How can seal wear be minimized? Use matching materials, check setup torque, and watch pressure to stop leaks and wear.

POOCCA – China’s Leading Hydraulic Radial Piston Motor Manufacturer

For tough jobs needing strong hydraulic solutions, POOCCA offers reliable hydraulic radial piston motors and parts. These are built to last in construction, mining, and farming. Started in 2006, POOCCA provides over 1,600 product types, including high-torque radial piston motors with displacements from 0.47 to 0.93 cubic inches and power up to 12 horsepower. They handle pressures up to 450 bar, fitting tough tasks.

To find dependable hydraulic radial piston motors or upgrade systems, visit POOCCA’s website or check their hydraulic motor catalog. Reach out via WeChat, email, or WhatsApp for specs, drawings, or custom solutions. Boost your machines’ performance with POOCCA’s expertise today.