In the world of hydraulische systemen, pumps are key. They turn mechanical power into hydraulic energy. Among many types, single-acting and double-acting hydraulic pumps are special. They work differently. Let’s dive into what makes them unique and how they fit various jobs.

What is a Single Acting Hydraulic Pump?

A single-acting hydraulic pump is a simple part. It’s used in systems where force goes one way. It creates pressure during one stroke of the piston or plunger. This makes it perfect for jobs that don’t need two-way movement.

Working Principle of Single Acting Hydraulic Pump

At its heart, a single-acting hydraulic pump is easy but strong. Its main parts are:

- Hydraulic Oil: This carries energy. It lubes and gives pressure.

- Hydraulic Cylinder: This holds the piston. It turns pressure into straight-line force.

- Single-Acting Pump: It has one inlet and one outlet. One-way valves control fluid flow.

The work happens in two steps:

Suction Step: The piston or rod pulls back. A spring or gravity helps. The inlet valve opens. Hydraulic oil flows from the tank into the pump chamber. This makes a vacuum. It pulls in fluid smoothly.

Push Step: The piston moves forward. A motor or hand crank drives it. The outlet valve opens. Pressurized oil goes into the cylinder. This pushes the piston out. It gives force for pushing, lifting, or pressing.

This one-way flow keeps things simple and trusty. But it only works for jobs where the return doesn’t need hydraulic power. For example, in a lifting system, gravity can pull things back. No need for powered return.

Advantages of Single Acting Hydraulic Pumps

Why pick a single-acting pump? Here are the top perks:

- Simple Build: It has fewer valves and ports. This makes setup and fixes easy. Teams learn it fast.

- Cheap to Buy: It costs less to make. It’s often 20-30% less than double-acting pumps. Great for tight budgets.

- Small Size: Its slim design fits tight spaces. Think portable tools or mobile gear.

- Saves Power for One-Way Jobs: It doesn’t waste energy on return strokes. This cuts power use in one-way tasks.

Disadvantages of Single Acting Hydraulic Pumps

No pump is perfect. Single-acting pumps have downsides:

- One-Way Only: They can’t power a return stroke. They rely on springs or gravity. This can fail with uneven loads.

- Slower Work Cycles: Non-hydraulic returns take time. This can slow down busy jobs.

- Less Flexible: They don’t fit complex motions. You might need extra parts like springs. This adds to system complexity.

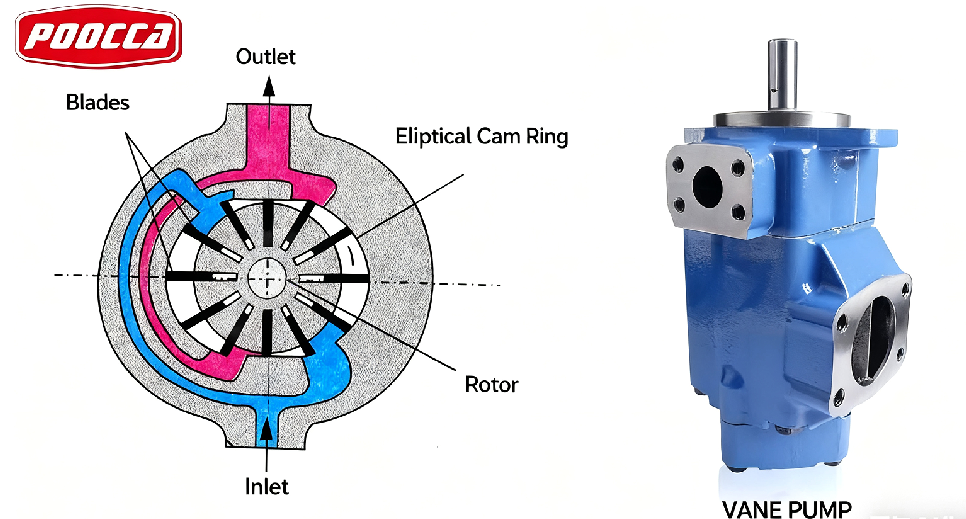

What is a Double Acting Hydraulic Pump?

A double-acting hydraulic pump shines in jobs needing force both ways. It gives more control and fits many tasks. It’s a strong choice for push and pull actions that matter equally.

Working Principle of Double Acting Hydraulic Pump

Double-acting pumps build on single-acting ideas. But they add two-way power with better fluid paths. Key parts are like single-acting but improved:

- Hydraulic Fluid (Oil): Keeps things smooth and cool under two-way stress.

- Hydraulic Cylinder: Has two ports for in and out. This lets pressure hit both piston sides.

- Double-Acting Pump: Has two inlets and one outlet (or dual paths). Multiple one-way valves give exact control.

The work goes like this:

Forward Stroke: Pressurized fluid enters the cap-end port. The pump sends it. This pushes the piston and rod out. It gives pushing force, like a single-acting pump.

Retournot: The pump switches flow (often with a control valve). Fluid goes to the rod-end port. This puts pressure on the other piston side. The rod pulls back smoothly. No outside help needed.

This two-way pressure makes smooth back-and-forth moves. It’s key for exact engineering. Searches like “double acting hydraulic pump diagram” show people want pictures to understand this fluid flow.

Advantages of Double Acting Hydraulic Pumps

Two-way power brings big wins:

- Full Control: Powered moves both ways give steady work. Great for auto systems.

- Faster Work: No need for extra parts like springs. This speeds up cycles and cuts wear on other bits.

- Fits Many Jobs: Handles tricky tasks like clamping, pressing, or placing with few add-ons.

- Handles Big Loads: Works better for uneven or heavy loads. This boosts safety and output in factories.

Disadvantages of Double Acting Hydraulic Pumps

Double-acting pumps have challenges:

- More Complex: Extra ports, valves, and seals raise leak or break risks. They need skilled fixes.

- Costs More: They’re pricier to buy—often 25-50% more. They also use more power due to constant fluid flow.

- Bigger Size: Bulkier builds don’t fit tight spots. This can make upgrades hard.

Buyers must balance these with long-term work gains.

The Difference Between Single-Acting and Double-Acting Hydraulic Pumps

Let’s compare single and double acting hydraulic pumps side by side. This table helps make choices clear:

| Aspect | Single-Acting Hydraulic Pump | Double-Acting Hydraulic Pump |

| Werkprincipe | One-way pressure. One stroke pushes. Return uses outside force. | Two-way pressure. Both strokes use hydraulic power. |

| Ports and Valves | One inlet, one outlet. Single one-way valve. | Two inlets/outlets. Multiple valves for flow switch. |

| Pressure Generation | One direction (push/lift). | Both directions (push and pull). |

| Efficiëntie | Great for simple jobs. Saves power on returns. | Better for cycles. Uses more power overall. |

| Kosten | Cheaper to buy and fix. | More expensive due to complex build. |

| Toepassingen | One-way moves (e.g., stamping). | Two-way moves (e.g., clamping). |

| Onderhoud | Simple. Fewer break points. | Trickier but lasts under load. |

In short, single-acting pumps focus on ease and low cost for simple jobs. Double-acting pumps are strong for complex tasks. Searches like “single vs double acting hydraulic cylinder pump differences” show this matters for picking gear.

Beyond the table, think about load needs. Single-acting fits short, gravity-helped tasks. It saves up to 40% energy in low-cycle jobs. Double-acting excels in non-stop work. Its two-way control stops jams and boosts accuracy. This is key for rules in industries like oil and gas.

Both pumps use eco-friendly oils now. But double-acting’s efficiency in busy cycles helps green goals by cutting idle power.

Practical Applications of Single and Double Acting Hydraulic Pumps

These pumps work in real-world jobs across industries. Here’s how they shine:

Applications of Single Acting Hydraulic Pumps

- Automatic Door Systems: In stores, single-acting pumps push doors open. Springs or weights close them. It’s simple and saves power.

- Punch Presses: Factory lines use them for one-way stamping or punching. Returns are manual or spring-based. This speeds up metal work.

- Hydraulic Rams for Water Systems: Farm water setups use gravity returns. This makes pumping easy and low-care.

These show single-acting’s role in cheap, one-way tasks.

Applications of Double Acting Hydraulic Pumps

- Car Jacks and Lifts: Car shops use them to raise and lower vehicles safely. They control heavy weights.

- Excavator Arms: Build gear uses double-acting for exact digging and lifting. It helps workers do more.

- Hydraulic Push-Pull Machines: In factory lines, they move parts both ways. This makes work smoother.

- Industrial Lifting Platforms: Warehouses use them for scissor lifts. They give trusty up/down moves for loading docks.

Frequently Asked Questions (FAQ)

Q: What is the main difference between single and double acting hydraulic pumps?

A: The big difference is direction. Single-acting gives pressure one way. It uses outside forces for return. Double-acting powers both ways for better control.

Q: Which is better for heavy lifting applications?

A: Double-acting pumps are usually better. They control both up and down moves. This makes heavy lifting safe and exact. Single-acting works for simple lifts with gravity help.

Q: How do I choose between single and double acting for my project?

A: Look at your motion needs. Pick single-acting for easy, budget-friendly one-way jobs. Choose double-acting for flexible, two-way tasks in tough settings.

Q: Are double-acting pumps more energy-efficient?

A: Not always. They use more power overall. But they’re efficient in back-and-forth jobs by skipping extra returns.

Q: Can single-acting pumps be converted to double-acting?

A: You can convert them. But it’s often not worth the cost. Pick the right type at the start or ask a pro for upgrades.

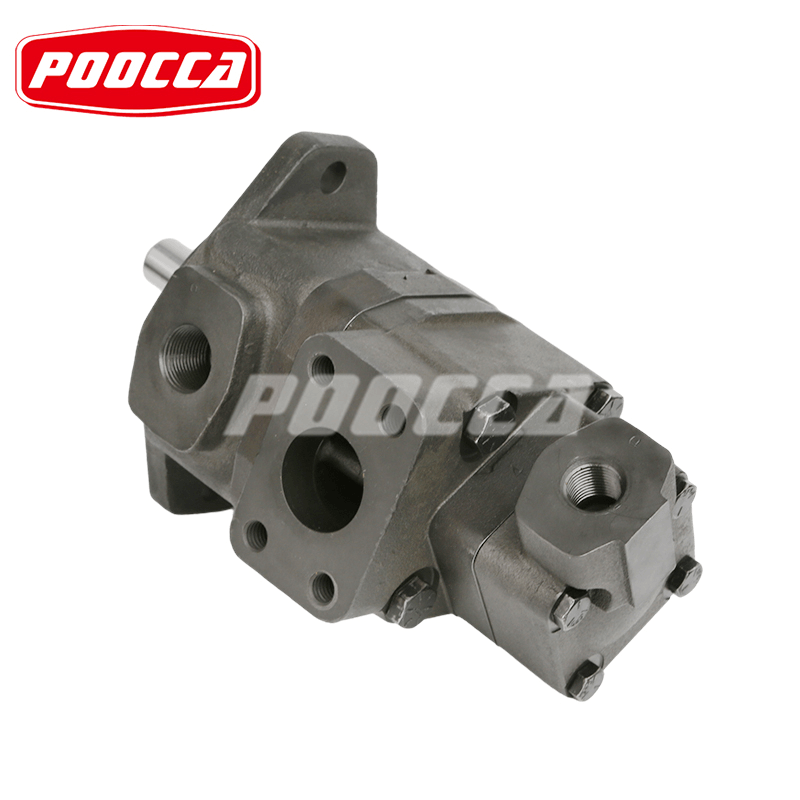

Partner with POOCCA for Premium Hydraulic Pump Solutions

Ready to boost your hydraulic systems with trusty, high-power pumps? At POOCCA , started in 2006 with over 20 years of know-how, we focus on making and supplying top single and double acting hydraulic pumps. They fit needs in building, farming, mining, and more.

Don’t go with basic suppliers. Team with POOCCA to get over 1,600 SKUs, fair order amounts, and expert help for smooth use. Whether you’re upgrading fleets or big projects, our solutions bring efficiency and trust.

Contact POOCCA Today! Fill our quick ask form or reach out. Our team replies in 24 hours. Let’s power your success! Visit www.kamchau.com to see our catalog and start your team-up.