Invoering

BEADE PUMPEN are positive displacement pumps. They are used in many areas like car systems, power steering, and air conditioning. These pumps work well with medium-thick liquids and are great for thin liquids. They help change high-pressure gas into low-pressure gas.

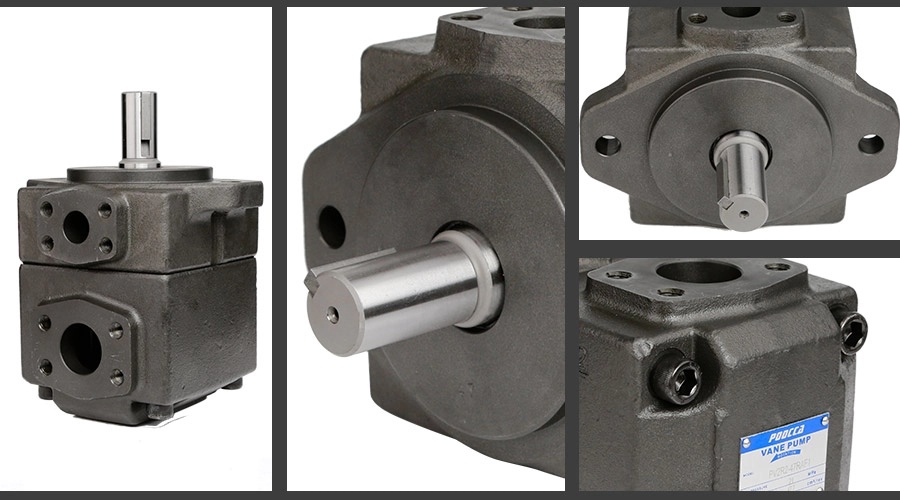

Vane pumps work with a simple but strong system. Flaps on a rotor slide in and out, touching the pump’s shell as the rotor spins. This creates spaces that grow and shrink, moving liquid from the inlet to the outlet. Based on their inner setup and use, vane pumps come in three main types.

Three Types of Vane Pumps

Unbalanced Vane Pumps

These pumps have a round rotor set off-center in a circular shell. The rotor’s center doesn’t line up with the shell’s center. There’s a clear gap between the two centers. This setup prevents leaks between the shell and flap tips.

But there’s a downside. Pressure differences between the inlet and outlet ports create a side push on the rotor shaft. This shortens the bearing’s life. These are called unbalanced vane pumps because of the uneven pressure, which causes this side force.

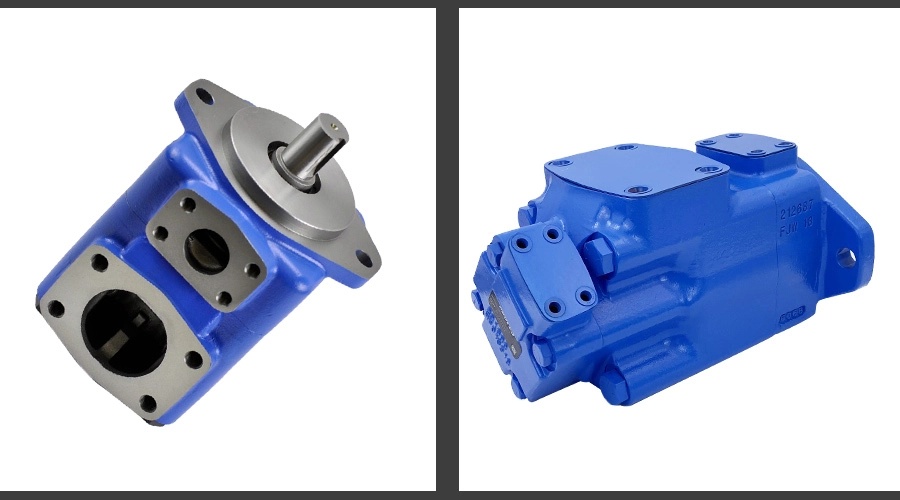

Balanced Vane Pumps

Balanced vane pumps have an oval-shaped shell with the same center as the rotor. There’s no offset. These pumps are built for flexibility and are used in mobile and factory settings.

They have two inlet ports and one outlet. This keeps pressure even between inlets and outlets. The two inlet ports and the outlet are placed opposite each other. This layout balances forces, stopping side push on the rotor shaft.

These balanced vane pumps work very well. They last a long time, often over 24,000 hours in factory use.

Variabele verplaatsing schoeppompen

These pumps let you change the size of the liquid pockets. This adjusts the flow rate based on the pocket size.

In these pumps, the flaps don’t touch the shell directly. A ring, called the response ring, sits between the flaps and the shell. One end of this ring links to a spring. The other end connects to an adjusting screw.

The screws change the pocket size. When the screw turns, the response ring moves up or down. This shifts the offset between the rotor’s center and the ring’s center. The changing offset affects the pocket size, which changes the pump’s flow rate.

Components of Vane Pumps

To understand vane pumps, it’s good to know their parts:

- Casing: The outer cover holds all the pump’s parts. It has two main pieces:

- Inlet Port: Where liquid enters the pump.

- Outlet Port: Where high-pressure liquid leaves the pump.

- Schacht: A shaft inside connects to a power source. A rotor sits on this shaft and spins with its power.

- Rotor: The rotor has evenly spaced slots around its edge. These slots hold sliding flaps.

- Sliding Vanes: These flaps sit in the rotor’s slots. They move freely due to spinning force or springs, staying in contact with the inner surfaces.

- Kokerring: This ring is on the shell’s inner wall. It shapes how liquid moves by forming pockets between flaps during spinning.

Why Choose POOCCA for Vane Pumps?

Pookca Hydraulic (Shenzhen) Co., Ltd., started in 2006. It has four locations in Hong Kong, Guangdong, Jiangsu, and Zhejiang. With over 26 years in hydraulics, POOCCA makes top-notch gear pumps, piston pumps, motors, and vane pumps, including high-quality hydraulic vane motors.

The company’s 8,000-square-meter factories use tools like CNC gear cutters and computer-run testing machines. This ensures precise products, like Parker T6 T7 Vane Pumps, which handle pressures up to 275 bar with great efficiency.

POOCCA works with brands like Rexroth, Parker, Yuken, and Danfoss for system compatibility. The team has over 300 workers, including 70 sales experts for custom advice and 18 tech specialists for new ideas.

Services include custom product design, fast global shipping, technical help, quality testing, and good prices for bulk orders. POOCCA exports $16 million yearly to over 100 countries, showing its global reach.

FAQ

What is a hydraulic vane pump?

A hydraulic vane pump is a positive displacement pump. It uses flaps to move liquid. As the pump spins, flaps slide in and out of the rotor, creating spaces that pull in and push out liquid. This turns mechanical energy into liquid energy.

What industries use hydraulic vane pumps?

They’re used in cars, factories, building, farming, marine, and aerospace. They’re great for systems needing medium pressure and smooth liquid flow, like steering systems, lifts, and power transfer.

What are the benefits of hydraulic vane pumps?

They offer:

- High efficiency and smooth work

- Low noise and shaking

- Ability to handle many liquid types

- Small and light design

- Steady liquid flow, great for mobile and factory use

How do you care for a hydraulic vane pump?

Check liquid levels and quality often. Look for leaks. Replace worn flaps, seals, or bearings. Clean the pump’s shell regularly. Using clean liquid and good filters helps the pump last longer.

How do you fix a hydraulic vane pump?

Issues like low pressure, low flow, or noise often come from:

- Dirty or low liquid

- Worn or damaged flaps

- Leaky seals or bearings

- Misalignment or cavitation

Check liquid, seals, and parts. Replace anything broken to fix issues.

What causes cavitation in hydraulic vane pumps?

Cavitation happens when liquid pressure drops too low, forming vapor bubbles. When bubbles collapse, they can harm pump parts. This may come from low liquid levels, wrong system pressure, or a blocked filter.

How do you pick the right hydraulic vane pump?

Consider system pressure, flow rate, temperature, liquid type, and the job it’s for. Match the pump’s specs to the system’s needs for good, reliable work.