Hydraulische motoren are devices that turn hydraulic power into spinning motion. They take in pressurized fluid from a pump and change it into mechanical force, which is vital for machines like construction tools and factory mixers. Picking the best hydraulic motor means you need to really know what your specific job requires, such as the weight it must handle, how fast it should go, and the conditions it will face.

Hydraulic motors as rotary actuators

By using the push and flow from a hydraulic pump, these motors spin to tug, push, or lift heavy stuff on all sorts of equipment, from building machines to kitchen blenders. As rotary actuators, their main job is to switch fluid energy into spinning power, making movement and strength possible in tons of factory tasks.

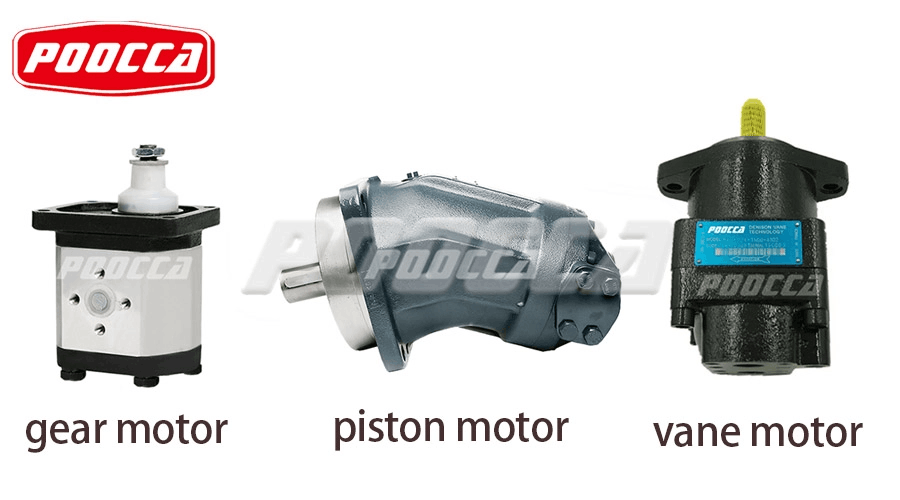

Common constructions: gear, vane, piston

There are three main kinds of hydraulic motors: gear, vane, and piston, each with its own special look. Gear motors are basic and cheap. Vane motors run more quietly and save energy better. Piston motors, on the other hand, give top-notch results and come with lots of ways to adjust them.

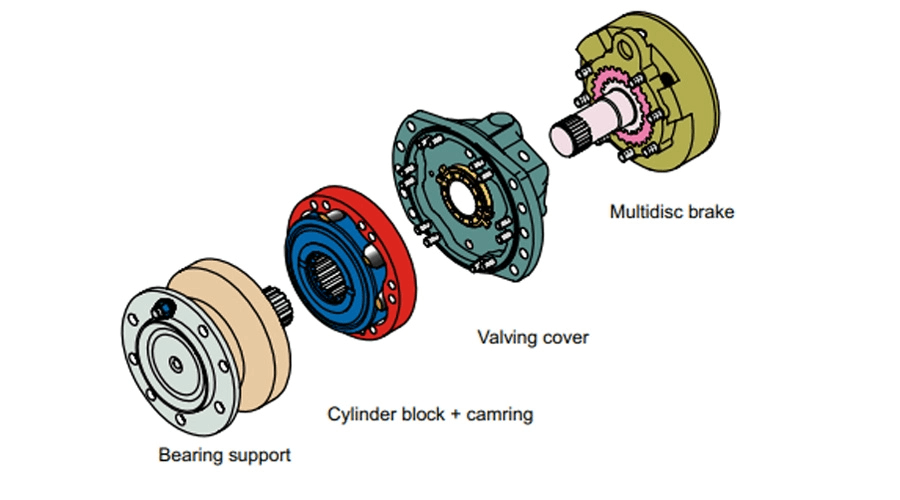

Orbital technology: gerotor and geroller motors

Some popular types use orbital designs, like gerotor and geroller motors. These setups have an inner piece and an outer piece (gerotor) or small rollers (geroller) to make slow, steady spins. The geroller style uses rollers to cut down on rubbing, boost power use, and give more starting strength compared to gerotor types.

Fixed vs. Variable Displacement Motors

Fixed-displacement characteristics

Makers provide fixed-displacement pumps in all major builds. A fixed displacement motor means the motor’s volume stays the same. Meanwhile, the force and speed change only if you tweak the flow or pressure in different ways.

Variable-displacement via swashplate control

A variable-displacement motor shifts its volume using swashplate control. This lets you change the force and speed on the go without messing much with the incoming flow.

Understand Motor Torque and Speed

Breakaway torque

Breakaway torque is often used to show the least force needed to get a motor moving when there’s no weight on it. It has to beat the inner drag and still resistance before it starts turning.

Running torque

Running torque is the force a motor needs to keep spinning and handle whatever turning task the machine has to do.

Starting torque

Starting torque is the smallest force required to get a motor going when there’s weight on it. It mixes breakaway torque with any extra push from the load.

Mechanical efficiency factor

The balance between real force and expected force tells us the mechanical efficiency factor of a hydraulic motor.

Displacement calculation

We figure out a hydraulic motor’s inner space to know how much fluid it moves in one turn. Bigger spaces mean more power but slower spins.

Efficiency considerations

Motors often get described with ideal numbers since leaks stop the real force from matching the expected force.

Formula for motor speed

You can work out motor speed with this simple rule: Flow in gpm times 231 divided by cubic inch displacement equals rpm.

Motor Type and Selection

Gear motors

Gear motors don’t cost much but usually work only with average pressure and force, plus a small range of volume. Their easy build makes them great for simple jobs that need quick spins without spending a lot.

VAE MOTORS

VAE MOTORS give a fair pressure and speed, run quieter, and save more energy than gear motors. They have sliding pieces in an off-center case to make them turn.

Piston motors (radial, axial, bent-axis)

Piston motors offer a big range of skills. Radial-piston motors have pieces set straight out. Axial-piston types have several pieces set inside a case.

Orbital motors (gerotor, geroller)

Orbital motors use a unique valve, either spool or disc. The gerotor style has a basic inner and outer part. On the other hand, the geroller type uses rollers instead.

Key Considerations for Selecting Hydraulic Motors

Maximum operating pressure, speed, torque

You’ve got to figure out the highest pressure, speed, and force the motor must handle.

Displacement and flow requirements

This helps you work out its volume and flow needs, making sure it matches the pump’s output.

Fluid compatibility and contamination resistance

Hydraulic motors can run on various fluids, but dirt in the fluid can cause trouble.

Cost vs. efficiency and life expectancy

Price plays a big role when picking any part. You also need to check the motor’s energy-saving score.

Maintenance, repair, interchangeability

A part that’s simple to fix will cut down on total system costs.

Size and weight factor

Think about the motor’s size and weight since it affects the whole system or machine’s bulk.

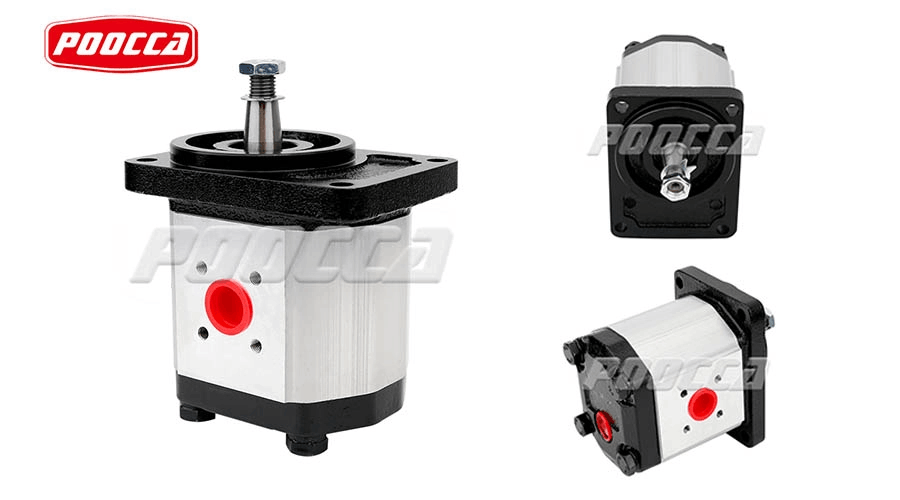

TOP China hydraulic motors manufacturer: POOCCA

Pookca Hydraulic (Shenzhen) Co., Ltd. started in 2006 and runs four branches in Hong Kong, Guangdong, Jiangsu, and Zhejiang. We’re a full-service hydraulic company focusing on creating, making, fixing, and selling hydraulic pumps, motors, valves, and related bits.

With a factory over 8,000 square meters, fitted with CNC gear grinders and auto-check systems, POOCCA builds custom hydraulic answers for fields like building machines, metal works, and farm tools. Our yearly export hits US$16 million, showing our solid place in the world market.

Their products include strong models like the Ronzio Z3 Series Gear Pump with up to 310 bar peak pressure, Parker TG Series Powertrain that can handle over 13,000 pound-inches of torque, and the efficient Poclain MS MSE Hydraulic Motors giving up to 240 kW power at 450 bar pressure.

POOCCA’s tech crew has over 18 skilled folks backed by more than 70 seasoned sales staff, ensuring great advice before buying and support after. For anyone wanting trusty supply lines with ISO-level quality, POOCCA shines as a top maker of hydraulic parts in China.

Contact us for an instant quote

To find out more about our products or get a price fit for your project, reach out to our sales team now for a quick quote.

FAQ's

Q1: What should I think about first when choosing a hydraulic motor?

A: The key things to look at are the needed force, speed, volume, and working pressure for your job. Once you know these, you can pick the motor type (gear, vane, piston, or orbital) that fits best.

Q2: What’s the big difference between fixed-displacement and variable-displacement hydraulic motors?

A: Fixed-displacement motors keep the same volume each turn, so speed and force depend on system flow and pressure. But variable-displacement motors can shift their volume on the fly, giving better control over speed and force.

Q3: Which hydraulic motor type saves the most energy?

A: Piston motors usually save the most energy. They handle high pressure, big force, and can adjust volume. However, they cost more than others.

Q4: How do I figure out a hydraulic motor’s speed?

A: You can find motor speed (rpm) with this rule: Flow (gpm) times 231 divided by Displacement (cu. in.) equals rpm.

Q5: Can hydraulic motors work with different fluids?

A: Yes, they can run on mineral oil, eco-friendly fluids, or fire-safe fluids. The fluid must suit the system needs and the motor’s seal materials to last long.