Invoering

Hydraulic setups need careful handling of fluid flow. The hydraulic control valve is super key for giving actuators the right push and fluid amount, oh boy. If a valve starts to fail, it can mess up the whole system. They manage fluid movement to make equipment work well and precisely, for sure.

For folks running machines or fixing them, catching early hints of a bad hydraulic control valve is crucial. It helps dodge downtime, keeps repair costs low, and stops other parts from getting hurt, by the way.

Signs of a Failing Hydraulic Control Valve

Spotting valve issues early can save bigger troubles later. Here are some clear signs a hydraulic control valve might be acting up, and all.

Valve Will Not Shift Positions

A big red flag is when the valve won’t switch spots. The inner spool might be stuck. Or something could be blocking it. If the actuator doesn’t budge when controls are used, a broken directional valve is often the culprit, for sure.

Erratic or Inconsistent Operation

Sudden surges or drops in hydraulic pressure

Weird or jumpy behavior, like quick spikes or dips in hydraulic pressure, can show up. These shifts might cause sudden actuator jerks. Or they could make the whole system shaky, oh man.

Irregular flow rates causing uneven movement in actuators

Odd flow speeds can lead to bumpy actuator moves. This often comes from wear inside the valve. Or dirt might mess up how well it controls fluid, by the way.

Leaking Hydraulic Fluid

Visible leaks around the valve housing or fittings

Fluid dripping near the valve body or connections is a problem. These leaks are easy to spot during a check. They often happen because of worn seals or cracked bits, and then some.

Loss of system pressure due to internal or external leaks

Pressure dropping in the system due to leaks inside or outside is another issue. Even if leaks aren’t visible, hidden ones inside can hurt how well the valve works. They let fluid slip past, for sure.

Reduced System Performance

Sluggish operation of hydraulic equipment

Slow or weak performance in hydraulic tools signals trouble. When valves can’t push enough fluid, actuators take longer to respond, oh boy.

Inability to achieve desired flow or pressure levels

This might mean the spools are worn out. Or ports could be clogged. Maybe the valve isn’t set up right in its assembly, and all.

Unusual Noises

Hissing, whistling, or knocking sounds indicating internal wear or contamination

Strange sounds like hissing, whistling, or banging can point to inner damage or dirt. These noises often mean cavitation, air sneaking in, or junk blocking normal flow, what’s more.

Oververhitting

Excessive heat in the valve or connected components due to fluid bypass or restricted flow

Too much heat in the valve or nearby parts can build up. This happens from fluid sneaking past or limited flow. The heat messes up the oil’s thickness. It also wears out parts faster, by the way.

Physical Damage

Visible cracks, corrosion, or wear on the valve body or internal components

Seeing cracks, rust, or wear on the valve body or inner parts is bad news. Such damage usually means the valve needs swapping out right away to avoid a total breakdown, for sure.

Causes of Hydraulic Control Valve Failures

Knowing why valves fail can help stop problems. Common reasons include:

Vervuilde hydraulische vloeistof

Dirty fluid with stuff like grit, tiny metal bits, or old oil can cause wear. It can also lead to blockages or bad sealing, oh man.

Improper Installation or Maintenance

Wrong setup or poor care can harm the valve. Uneven connections, overly tight fittings, or skipping regular checks are culprits, by the way.

Excessive Pressure or Flow

Using a valve beyond its safe pressure or flow limits can break inner parts. It can also cause leaks, for sure.

Normal Wear and Tear

Over time, parts like seals and spools wear out. This lowers how well the valve works and its efficiency, and then some.

Troubleshooting a Faulty Valve

When a hydraulic control valve seems off, try these steps:

Inspect for Leaks

Look closely at the valve body, fittings, and seals. Check for any signs of fluid dripping out, oh boy.

Test System Pressure

Use a pressure tool to see if the system runs within its safe range, for sure.

Check for Contamination

Take a fluid sample. Look for dirt or strange colors that shouldn’t be there, by the way.

Evaluate Actuator Performance

Watch the connected cylinders or motors. See if they move as they should, and all.

Measure & Compare Current (Amperage)

Check the current (Amperage). Make sure it matches the maker’s rules, for sure.

Confirm Manual Actuation

If it’s a hand-operated valve, ensure the manual control still works, what’s more.

If these steps show the valve is broken, consider swapping it for a solid option like Vickers valves. They’re known for being reliable in many uses, and then some.

Hydraulic Flow Control Valves 101

Flow control valves handle how fast fluid moves in a hydraulic setup. These valves adjust flow to actuators like motors and cylinders. This controls their speed, by the way.

How much fluid flows decides how much power is passed on at any moment. Actuator strength times the distance it moves equals the work done on a load. This shows why managing speed with good flow control is key, especially for precise movements.

FAQ

1. What is a hydraulic control valve?

A hydraulic control valve manages the flow, pressure, and path of fluid in a system. It controls how fast and in what way actuators like cylinders and motors move, for sure.

2. What are the main types of hydraulic control valves?

- Directional control valves (DCVs): Guide fluid flow to actuators.

- Pressure control valves: Keep system pressure safe.

- Flow control valves: Adjust actuator speed, by the way.

3. How do hydraulic control valves work?

They use parts like a spool, poppet, or rotating piece to open, shut, or switch fluid paths. This can be done by hand, with fluid, air, or electric power, and all.

4. Where are hydraulic control valves used?

They’re found in building machines like excavators and loaders, farm tools, factory presses, and sea or offshore hydraulic setups, oh man.

5. What factors should I consider when selecting a hydraulic control valve?

- Operating pressure and flow speed

- How many actuators need control

- Type of control (hand, electric, or hydraulic)

- Port size and setup

- Conditions like heat, dirt, or exposure, for sure.

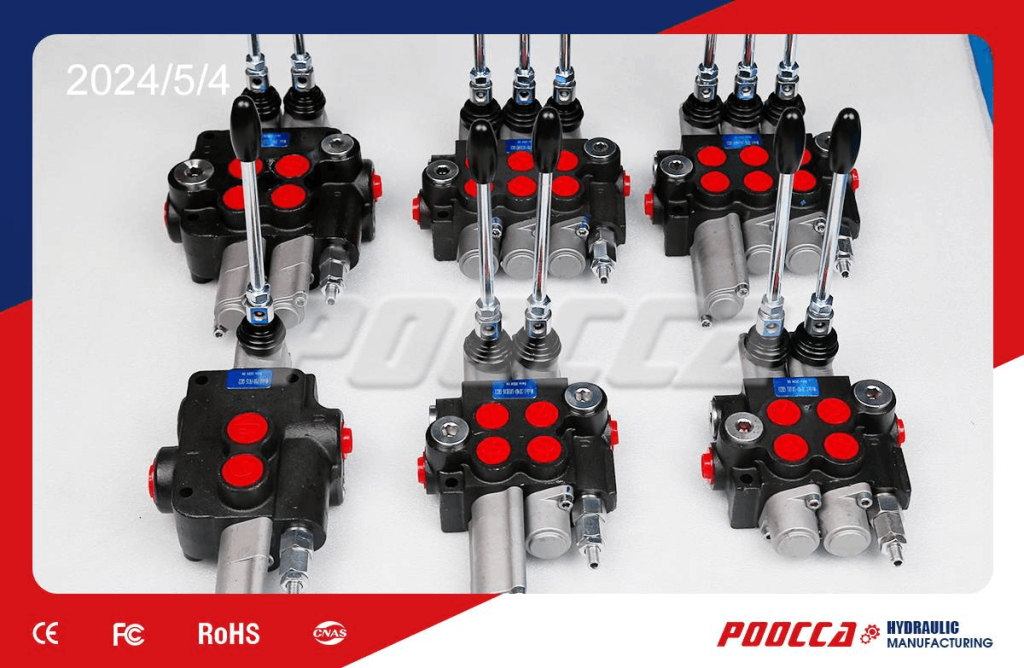

Get a Quote on Hydraulic Control Valves from POOCCA Now

For trusty performance in fields like building equipment and material moving systems, POOCCA has custom solutions. They’ve got over 20 years of know-how in making top-notch valves, what’s more.

With high-tech tools like CNC machining centers and auto testing setups, POOCCA ensures every item meets tough quality rules. Whether directional valves like the P40/P80/P120 series with up to 315 bar pressure, or small combined valves like P120 with 31 GPM power, they’ve got what’s needed for your setup, by the way.

Reach out to the sales crew today for help picking the right hydraulic control valve. Full support from start to finish, including after-sales help, is provided. POOCCA sends products worldwide, working with over 75 countries, making them a dependable choice for tough hydraulic answers, and then some.