Understanding Fixed and Variable Displacement Pumps

Knowing the difference between a fixed displacement pump and a variable displacement pump is key. It helps pick the right tool for hydraulic jobs. Each type has unique features, benefits, and limits. These affect performance, energy use, and upkeep needs.

What Is a Fixed Displacement Pump?

A fixed displacement hydraulic pump gives a steady amount of fluid each cycle. It doesn’t change, no matter the pressure or load. This steady flow is great for jobs needing constant fluid movement.

How Fixed Displacement Pumps Operate

These pumps are simple. They push out the same fluid volume every cycle. The amount stays fixed for each stroke. Once running, they keep delivering the same fluid per turn of the drive shaft.

Types of Fixed Displacement Pumps

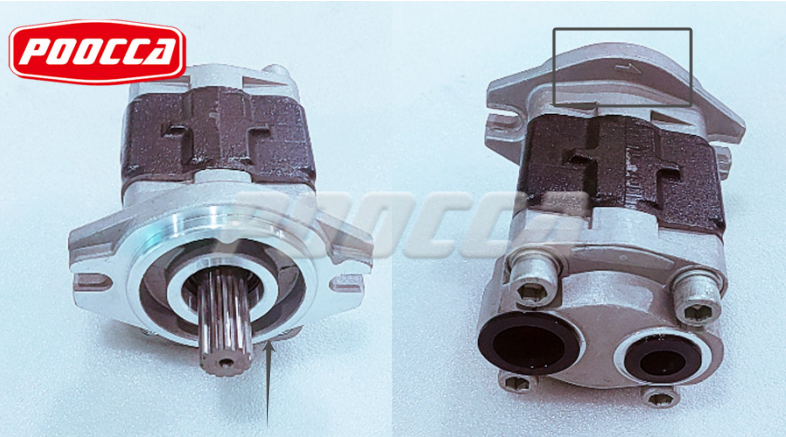

Versnellingspompen

Versnellingspompen, like internal or external types, are fixed displacement pumps. They make a steady flow. They’re simple and tough. Also, they’re cheap, stay cool, work fast, move lots of fluid, and are quiet.

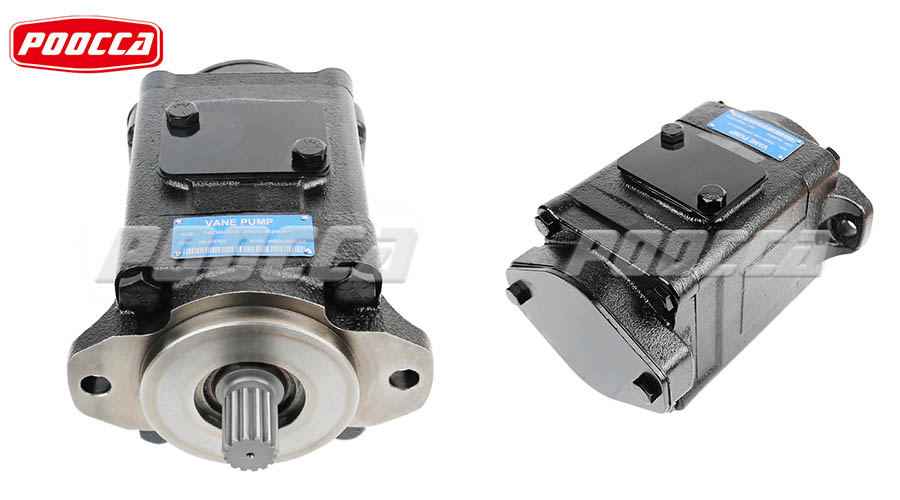

BEADE PUMPEN

BEADE PUMPEN use sliding vanes in a rotor to move fluid. They’re less common than gear pumps in some fields. But they give smooth flow and work well under medium pressure.

Zuigerpompen

Vaste verplaatsing zuigerpompen use moving pistons to push fluid. They’re great for high-pressure jobs. But they’re more complex than gear or vane types.

Key Characteristics of Fixed Displacement Pumps

- Steady flow rate, no matter the demand.

- Simple design and lower cost.

- Easy to maintain.

- Less flexible control.

- Tough in dirty settings.

Veel voorkomende toepassingen

Fixed displacement pumps are perfect for machines needing high fluid pressure. They handle different fluid thicknesses. They’re great for dirty industrial settings.

Typical uses include:

- Material handling.

- Machine tools.

- Industrial manufacturing machines.

- Marine applications.

- Agricultural equipment.

- Lubrication systems.

Considerations

Check the flow rate needs. If a system needs steady fluid flow and pressure, a fixed displacement pump is best. Also, for constant speed, these pumps are a great match.

What Is a Variable Displacement Pump?

Variable displacement pumps let the fluid amount change per cycle. This flexibility allows control over flow and pressure in real time.

How Variable Displacement Pumps Operate

These pumps are called variable because the fluid volume can change. It adjusts during operation, using electronic, hydraulic, or manual controls. This adaptability makes them flexible but more complex.

Soorten variabele verplaatsingspompen

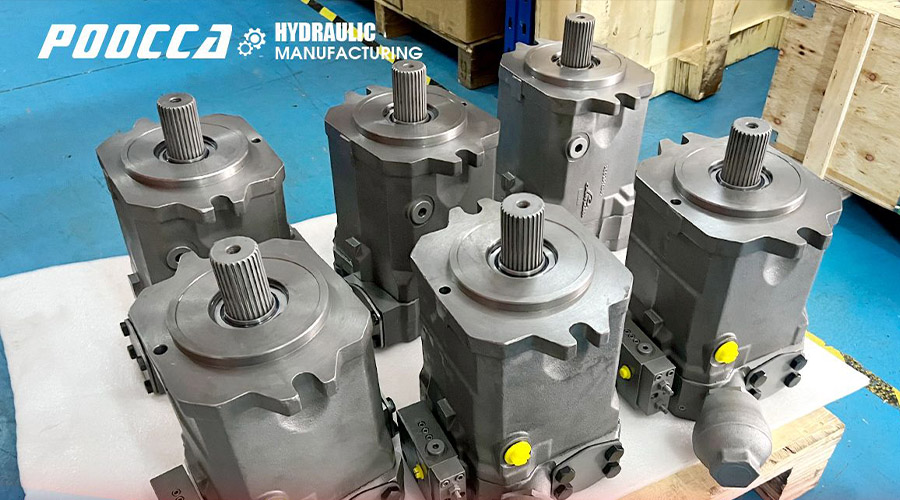

Axiale zuigerpompen

These use pistons lined up with the drive shaft. A swashplate controls piston stroke length. Changing its angle adjusts the flow easily.

Bent Axis Pumps

In these, pistons sit at an angle to the drive shaft. Changing this angle varies the flow. They’re very efficient and strong at high pressures.

Key Characteristics of Variable Displacement Pumps

- Adjustable flow based on load needs.

- Saves more energy.

- More complex design.

- Higher starting cost.

- Needs advanced control systems.

- Great for changing loads.

Veel voorkomende toepassingen

Variable displacement pumps are common in heavy machines like cranes, excavators, and backhoes. They’re used where fluid pressure must adjust for different loads.

Common uses include:

- Industrial automation systems.

- High-performance machine tools.

- Marine propulsion systems.

- Mining equipment.

- Medical devices.

- Wind turbines.

- Injection molding machines.

- Some harvesters and tractors.

Considerations

If a job needs adjustable speed or flow, a variable displacement pump is needed. Also, if flow must change based on load, these pumps are key. They save energy over time due to flexibility. But they cost more upfront and need more upkeep.

Select the Right Hydraulic Pump With Help From POOCCA

Pookca Hydraulic (Shenzhen) Co., Ltd. has over 26 years in hydraulic technology. They’re a trusted provider of pumps, motors, valves, and parts.

Their 8,000-square-meter facility has CNC gear grinders, flexible machining centers, and automatic testing systems. These ensure reliable products for construction, farming, injection molding, metallurgy, petroleum, and more.

Whether it’s a tough gear pump like the Ronzio Z2 for high-pressure jobs or an advanced axial piston pump like the Eaton Vickers PVH series for up to 250 bar, POOCCA has solutions.

Their team of over 300, including 70 sales experts and 18 technical specialists, helps pick between fixed or variable displacement pumps. They offer custom consulting and maintenance support.

Choosing between these pumps depends on pressure stability versus flexibility. POOCCA’s catalog covers over 1,600 categories, including Yuken PV2R series vane pumps and Parker PGP505 gear pumps.

For expert advice tailored to industries like agriculture or marine propulsion, contact POOCCA for personalized help from a top Asian hydraulic provider.