What is a Hydraulic Piston Pump?

The piston pump can be defined as it is a positive displacement pump. These pumps use a piston, diaphragm, otherwise plunger for moving liquids. These pumps use check valves as the input and output valves. The general piston-pump is a rotary pump which uses a wheel or revolving shaft for operating the piston.

This type of pump is widely used in hydraulic systems due to its ability to generate high pressure and handle viscous fluids. The core components include a chamber, piston, and control valves that regulate fluid intake and discharge.

Hydraulic Piston Pump Working principle

The piston pump working is similar to PD pumps. Because they work with the help of the pumping mechanism force to increase the volume of the liquid. These pumps include more than one piston with a set of control devices.

When the air pressure surpasses from the opening valve spring, then the reduced media can be sent throughout the open exit valve. As the piston is drawn back-up, then it releases the inlet valve & shuts the outlet valve, thus suction can be used to draw in extra media for compression.

Depending on design, these pumps can be single-acting or double-acting. Double acting pumps involve two sets of controlling devices & liquid on both ends. This lets the pump to complete a pumping cycle by flowing in one direction to other.

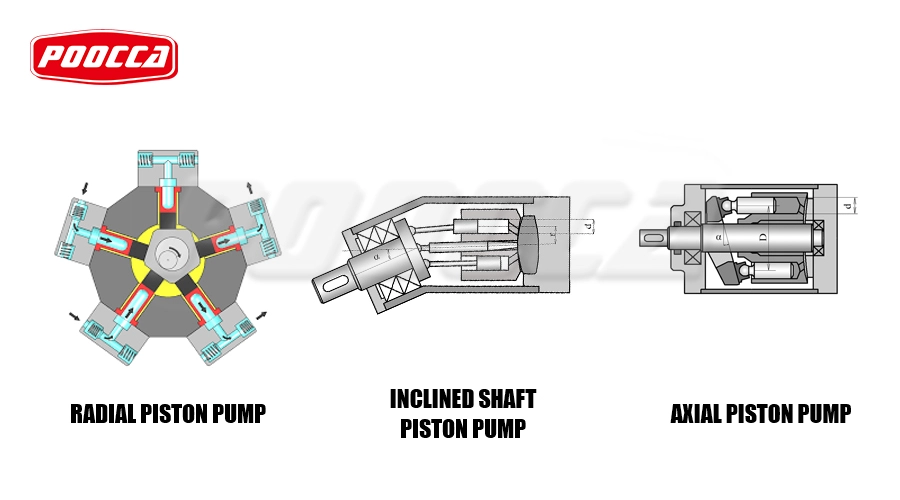

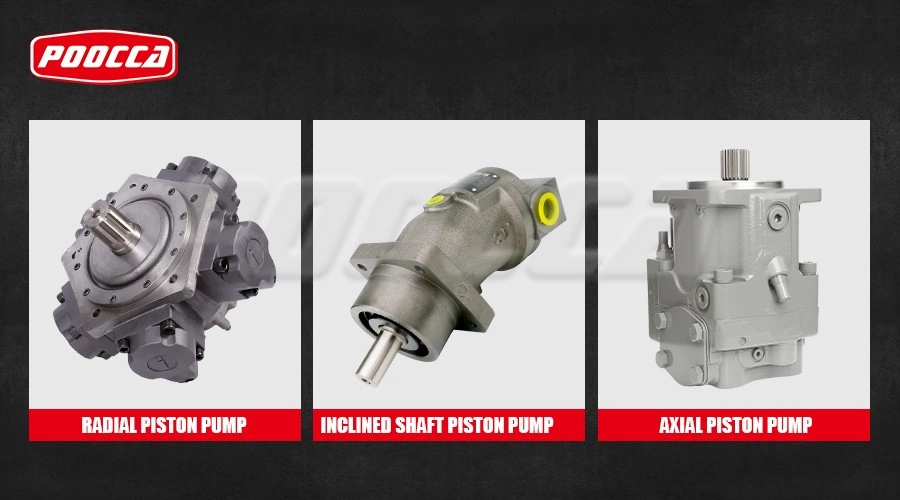

Types of Hydraulic Piston Pumps

These pumps are classified into different types namely lift pump, a force pump, axial pump, and radial piston-pump. From these pumps, lift and force pumps can operate manually otherwise with the help of an engine.

Each type has unique characteristics suited for specific applications ranging from manual fluid transfer to high-pressure industrial operations.

Hydraulic Lift Piston Pump

In this type of pump, the piston above stroke can draw fluid with the help of a control device which is named as valve into the below portion of the cylinder. On the below stroke, fluid flows through control devices which are arranged in the piston into the higher portion of the cylinder. After that on the upstroke, fluid can be released from the higher portion of the cylinder through a spout.

Lift piston pumps are commonly used in well water systems and other low-pressure applications.

Hydraulic Force Pump

In this type of pump, the piston pumps upstroke can draw fluid throughout an inlet valve to the cylinder (tube). On top of the downstroke, the fluid level can be discharged via an exit valve into the outlet tube.

Force pumps are often preferred when fluid needs to be delivered at higher pressures over longer distances.

Hydraulic Axial Piston Pump

Hydraulic Axial Piston Pump is pump is a PD (positive displacement) pump and it has several pistons within a circular array of a tube block. This block can be driven to turn its symmetry axis with an important shaft which is associated with the pumping pistons.

Axial designs are widely used in automotive air conditioning compressors and hydraulic motors due to their compact design and high efficiency.

Hydraulic Radial Piston Pump

Hydraulic Radial Piston Pump is one kind of hydraulic pump, and the working pistons expand within a radial track symmetrically in the region of the drive shaft, in disparity in the direction of the axial piston pump.

Radial configurations offer superior performance under high-pressure conditions and are commonly found in heavy-duty industrial machinery.

Specifications of Hydraulic Piston Pump

The main specifications while choosing these pumps mainly include the rate of flow, head of the pump, volume stroke, pressure, outlet diameter, power rating, horsepower, and finally operating temperature.

These parameters help determine whether a specific model meets your application’s requirements regarding performance and compatibility.

Materials of Hydraulic Piston Pump

The materials used to design the piston-pump mainly depend on the application of a pump. The casing and cylinder materials must have sufficient strength as well as they have to hold up adjacent to the operating environment conditions.

Some commonly used materials include:

- Cast iron offers high tensile power, robustness, and scratch resistance equivalent to high force ratings.

- Plastic materials are cheap as well as offer a wide resistance toward rust as well as chemical attack.

- Stainless steel alloys and steel give safety against rust and chemical and they have superior tensile powers compare with plastics

- Other types…include aluminum, brass, bronze, ceramics, and nickel-alloy.

Advantages of Hydraulic Piston Pump

The advantages of a piston pump mainly include…The range of pressure is wide, making them suitable for various applications.

- Force can be managed without moving flow rate

- Skilled in moving thick fluids…with good control device design

- High efficiency even under variable loads

- Reliable operation in harsh environments

Disadvantages of Hydraulic Piston Pump

Despite their advantages:

- Maintenance cost & operating is high usually bulky and heavy

- They handle only lesser flow rates

- Flow is Pulsating

These factors must be considered when selecting them for continuous or large-scale operations.

choose POOCCA for your China Hydraulic Piston Pump manufacturer

POOCCA Hydraulic (Shenzhen) Co., Ltd. was established in 2006. We are a comprehensive hydraulic service company specializing in research and development.

With over 26 years in hydraulic manufacturing experience across four locations including Guangdong and Jiangsu provinces,POOCCA exports products worth $16 million annually across 100+ countries.

Our factory spans over 8,000 square meters equipped with CNC gear grinders,coordinate measuring machines. CAT fully computer-controlled testing machines… ensuring precision manufacturing quality.

We offer extensive product lines including gear pumps like Ronzio Z3 Series Gear Pump,

Parker TG Series Powertrain units,

and Rexroth A10VSO Series Axial Piston Variable Pumps.

Please contact our sales team for customized solutions tailored specifically for your needs.

FAQ

How does a piston pump work?

The piston moves within a chamber, creating a vacuum that draws fluid into the pump. As the piston moves back, it releases the inlet valve, closes the outlet valve, and draws in more fluid. The fluid is then compressed and discharged when the piston moves forward.

What are the types of piston pumps?

Piston pumps are typically classified into two categories: lift pumps (which operate manually or with an engine) and force pumps (which use a piston to draw fluid through an inlet valve). Other types include axial piston pumps and radial piston pumps.

What are the advantages of piston pumps

Piston pumps offer high pressure, excellent control over flow, and the ability to pump thick fluids or slurries. They are also reliable and can provide a smooth, pulse-less flow.

How do lift and force piston pumps differ?

Lift pumps are used for drawing fluid into the pump via manual or engine power, while force pumps use a piston to push fluid through the system under pressure. Force pumps are generally more suitable for high-pressure applications.

What is the difference between axial and radial piston pumps?

Axial piston pumps have pistons arranged in a circular array, typically used in hydraulic systems, while radial piston pumps feature pistons arranged radially around the drive shaft and are typically used in high-pressure, low-flow applications.