What’s a Radial Piston Hydraulic Motor?

Radial piston motors are tough, slow-spinning, high-torque (LSHT) machines. They churn out way more torque than axial piston motors. Plus, they don’t need a gearbox to ease up on speed. That makes them awesome for heavy tasks where raw power trumps going fast.

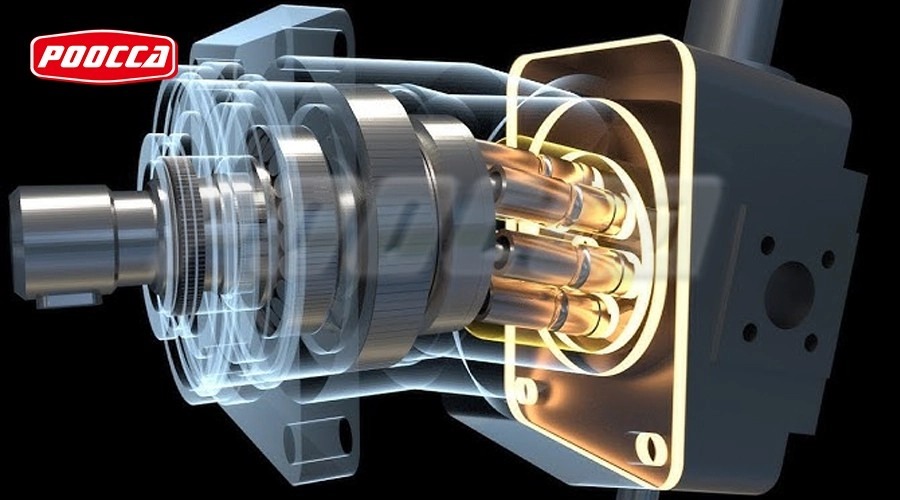

In a radial piston motor, pistons (or plungers, sometimes) are set up like a star around the crankshaft’s middle. They’re all on one flat level. When the pistons slide in and out, a wonky shaft turns that straight push into a spinning move. This setup lets them pump out huge torque at low speeds super smoothly.

Their solid build and big power make radial piston hydraulic motors a go-to for giant construction gear. Think full-size excavators and backhoes. These beasts need strong force to dig, hoist, or shove heavy stuff in tough spots.

What’s an Axial Piston Hydraulic Motor?

Axial piston motors don’t hit as hard on torque as radial ones, but they’re cheaper and tiny. A 5-hp axial piston motor is about the size of a soda can! Their small size and low price make them perfect for jobs where space is tight and medium power gets it done.

In an axial piston motor, pistons sit in a circle inside a spinning part called a cylinder block. A shaft runs right through the center, lined up with the pistons, which all stay parallel to each other. There are two main kinds: swashplate and bent-axis. In the swashplate type, pistons and the shaft stay side by side. In the bent-axis type, pistons tilt at an angle to the shaft.

These designs let axial piston hydraulic motors zip along faster than radial ones. They’re often found in speedy gear like compact track loaders, mini-excavators, and skid-steers, where quick moves matter more than brute strength.

How Do Radial and Axial Piston Motors Compare?

The big deal between radial piston motors and axial piston motors is torque versus speed. Radial motors have a small speed range but kick out tons of torque. Axial motors, though, can race at higher speeds with less power.

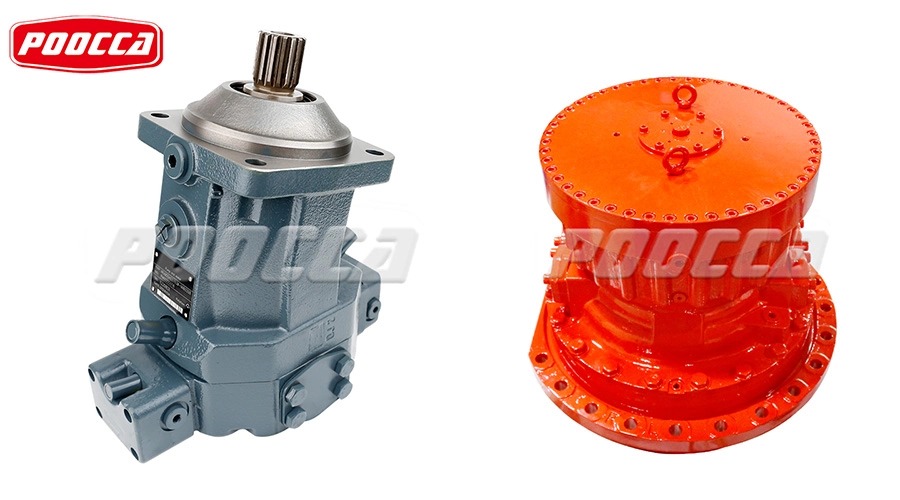

This gap shows why each fits different jobs. Radial piston motors rock in heavy gear like full-size excavators and backhoes, where power rules. Axial piston motors pop up in smaller, nimble machines like skid-steers, mini-excavators, and compact track loaders.

Money matters too when choosing. Axial designs are easy on the wallet and super compact but skimp on torque. Radial designs bring massive torque without extra gear setups, but they cost more and take up more room.

Hydraulic motors are super important for turning hydraulic energy into spinning motion and torque for machines. Picking between radial and axial depends on the job’s needs, like load size, space, speed, budget, and how much upkeep is okay.

Quick Rundown

In short, the two main types of hydraulic motors for heavy gear are radial piston and axial piston motors. Radial ones dish out huge torque but move slow. Axial ones zip fast but don’t pack as much punch. Radial designs are champs for jobs needing big power at low speeds without a gearbox. Axial setups work great for smaller machines where speed beats raw force.

Getting these differences helps engineers, tech folks, and operators choose the best hydraulic motor for top performance in specific tasks. Check out hydraulic motor options at POOCCA.

About POOCCA Hydraulic (Shenzhen) Co., Ltd

POOCCA Hydraulic (Shenzhen) Co., Ltd started up in 2006. They’ve got four locations in Hong Kong, Guangdong, Jiangsu, and Zhejiang. They’re a one-stop spot for hydraulic pumps, motors, valves, and parts, handling research, building, fixing, and selling.

With over 20 years of rolling out awesome power solutions worldwide, POOCCA has solid connections with dealers in over 75 countries, like the USA, Indonesia, Mexico, Thailand, Russia, and Brazil. Their 8,000-square-meter factory uses neat tech like flexible machining centers, CNC gear grinders, and CAT testing machines to craft super precise radial piston hydraulic motors and axial ones. Whether it’s high-torque motors for mining or tiny systems for farm gear, POOCCA whips up custom solutions with expert engineering. They team up with big brands like Rexroth, Parker, and Danfoss to level up their products across industries.

FAQ

How Long Has POOCCA Been Running?

POOCCA, a hydraulic manufacturer, kicked off in 2006 and has 26 years in the hydraulic world.

What Stuff Does POOCCA Make?

They’ve got 1,600 product types, like gear pumps, piston pumps, vane pumps, motors, hydraulic accessories, and valves.

Do They Ship Everywhere?

Yup, POOCCA offers quick international shipping for easy access.

What’s Their Warranty Like?

They offer a 12-month warranty.

Can I Get Help with Setup or Tech Stuff?

Yeah, POOCCA gives online setup guides, maintenance tips, and tech support for their products.

Do They Make Custom Stuff?

Sure do! POOCCA crafts custom hydraulic solutions to fit specific needs, including packaging options.

How Do I Choose Between Radial and Axial Piston Hydraulic Motors?

Look at the job: radial for big torque at slow speeds, axial for small, speedy setups with medium loads.

For solid, high-performance hydraulic motors, including radial piston and axial types, POOCCA’s your trusty global partner. Dive into their full range at www.poocca.com for custom fixes that match any job!