Hydraulic cylinders are essential components in various industrial and mechanical applications, known for their ability to generate linear force and motion. To understand how to identify a hydraulic cylinder, one must be familiar with its characteristics, key components, and different types available. This article will guide you through all you need to know about hydraulic cylinders.

Understanding Hydraulic Cylinders

Definition and Basic Function

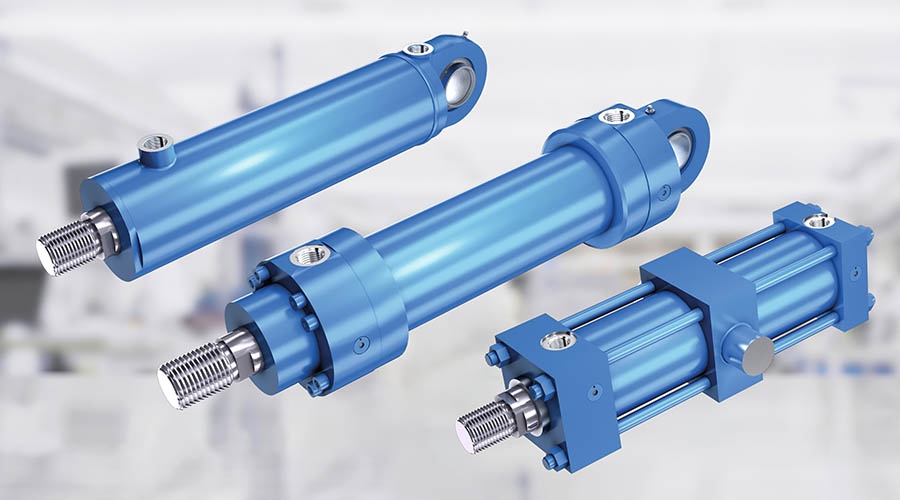

A hydraulic cylinder, fundamentally a mechanical actuator, serves the purpose of transforming hydraulic energy into linear motion and force. This operation is facilitated by pressurized hydraulic fluid that propels a piston within the cylinder barrel, thus creating a linear pushing or pulling force. Such mechanisms are pivotal in applications demanding robust and precise movements, prominently within the construction, manufacturing, and automotive industries.

Common Applications of Hydraulic Cylinders

Hydraulic cylinders are versatile and can be found in numerous applications, ensuring efficient and powerful operations. Common uses include:

- Construction Equipment: Excavators, bulldozers, and cranes rely on hydraulic cylinders for digging, lifting, and moving heavy materials.

- Industrial Machinery: Hydraulic cylinders are critical in presses, injection molding machines, and metal forming equipment, providing the necessary force for various manufacturing processes.

- Agricultural Machinery: Tractors, harvesters, and plows utilize hydraulic cylinders to perform various tasks such as lifting and tilting.

- Automotive Systems: In automotive contexts, hydraulic cylinders are found in braking systems, suspension systems, and convertible roofs.

Key Components of Hydraulic Cylinders

Cylinder Barrel

The cylinder barrel is the main body of the hydraulic cylinder, housing the piston and hydraulic fluid. It is typically made of high-strength steel to withstand the high pressures and dynamic forces exerted during operation. The interior surface is precision-machined for smooth piston movement, preventing leakage and ensuring efficiency.

POOCCA Hydraulic (Shenzhen) Co., Ltd. was established in 1997 and has four companies in Hong Kong, Guangdong, Jiangsu and Zhejiang. We are a comprehensive hydraulic service company specializing in the research and development, manufacturing, maintenance and sales of hydraulic pumps, motors, valves and related parts. With extensive experience in providing power transmission and drive solutions to hydraulic system users around the world, we have a strong reputation in the industry.

Piston and Piston Rod

The piston is a vital component that separates the interior of the cylinder into two chambers—the cap end and the rod end. As hydraulic fluid enters either chamber, it moves the piston to create linear motion. Attached to the piston is the piston rod, which extends from the cylinder barrel to transfer the generated force to the connected load. The piston rod is usually crafted from hardened steel to resist wear and deformation.

Seals and Gaskets

Seals and gaskets play a crucial role in maintaining the integrity of the hydraulic system by preventing fluid leakage and contaminant ingress. Various types of seals, such as rod seals, piston seals, and wiper seals, ensure that the hydraulic fluid remains contained within the cylinder, thus maintaining operational efficiency and extending the lifespan of the machinery.

End Caps and Mounting Accessories

End caps are mounted at both ends of the cylinder barrel, providing structural support and sealing the cylinder. They house ports for the hydraulic fluid to enter and exit. Additionally, mounting accessories such as clevises, trunnions, and flanges are used to secure the hydraulic cylinder to the machinery, ensuring stable and precise operation.

Types of Hydraulic Cylinders

Single-Acting Cylinders

Single-acting cylinders rely on hydraulic pressure to move the piston in one direction, with a spring or external force returning it to its original position. These cylinders are commonly used in applications requiring linear motion in one direction, such as in jacks and clamping devices.

Double-Acting Cylinders

Double-acting cylinders use hydraulic pressure to move the piston in both directions, offering greater control and efficiency. They are widely used in applications requiring precise and continuous back-and-forth motion, such as in robotic arms and industrial presses.

Telescopic Cylinders

Features and Applications of Telescopic Cylinders

Telescopic cylinders consist of multiple nested tubular sections that extend and retract, providing a longer stroke from a compact design. These cylinders are ideal for applications with limited installation space but requiring significant extension lengths, such as dump trucks and aerial work platforms.

Identifying Hydraulic Cylinder Specifications

Bore Diameter

Bore diameter is a critical specification for hydraulic cylinders, referring to the inside diameter of the cylinder barrel. The bore size directly affects the force the cylinder can generate; a larger bore diameter results in higher force output for a given hydraulic pressure. Accurate identification of the bore diameter is essential for selecting a cylinder that meets the application’s load requirements and ensuring compatibility with existing hydraulic systems.

Stroke Length

Stroke length pertains to the distance the piston rod travels from its fully retracted to fully extended position. This measurement is crucial in determining the range of motion the cylinder can provide. Identifying the appropriate stroke length is vital for ensuring that the hydraulic cylinder can achieve the desired movement and positioning within the application’s operational constraints.

Mounting Type

Mounting type is another significant consideration, as it influences the installation and stability of the hydraulic cylinder. There are several mounting styles, each suited for different applications and load conditions:

- Flange Mounts: Provide a rigid and stable mounting option, ideal for high-force applications.

- Clevis Mounts: Allow for pivoting motion, suitable for applications where the load direction changes.

- Trunnion Mounts: Enable rotational movement around the trunnion axis, useful for complex machinery with multiple degrees of motion.

Choosing the correct mounting type ensures proper alignment and efficient force transfer, enhancing the performance and lifespan of the hydraulic cylinder.

Inspection and Maintenance

Visual Inspection Techniques

Visual inspection is crucial for identifying potential issues early and ensuring the safe operation of hydraulic cylinders. Key steps include checking for visible leaks, cracks, and dents on the cylinder barrel, piston rod, and end caps. Examining the seals and gaskets for signs of wear or damage is essential to prevent fluid leaks and contamination. Regular inspections help in maintaining optimal performance and avoiding costly repairs.

Regular Maintenance Practices

Implementing a regular maintenance schedule is integral to the longevity of hydraulic cylinders. Lubrication is a key practice, ensuring all moving parts function smoothly and reducing wear. Using the appropriate hydraulic fluid and maintaining the correct fluid levels are vital to prevent overheating and fluid degradation. Cleaning the exterior of the cylinder and inspecting for dirt or debris buildup can prevent operational issues and contamination of the hydraulic system.

Selecting the Right Hydraulic Cylinder for Your Needs

Evaluating Performance Requirements

When selecting a hydraulic cylinder, it’s essential to evaluate the performance requirements of the application. This includes understanding the pressure ratings and load capacities needed to perform the required tasks efficiently. Ensuring that the selected cylinder can withstand the specific operational pressures and handle the expected loads is critical for safe and efficient performance.

Compatibility with Existing Systems

Compatibility with existing hydraulic systems is another crucial consideration. This involves ensuring that the hydraulic cylinder’s specifications, such as bore diameter, stroke length, and mounting type, align with the existing system’s parameters. Additionally, verifying that the hydraulic fluid and pressure settings are compatible helps in achieving seamless integration and optimal performance.

Benefits of Proper Identification and Selection

Operational Efficiency

Proper identification and selection of hydraulic cylinders directly contribute to operational efficiency. Choosing a cylinder that meets the exact specifications and performance requirements ensures smooth and efficient operation, minimizing downtime and enhancing productivity.

Extending Equipment Lifespan

Selecting the right hydraulic cylinder and maintaining it properly can significantly extend the lifespan of both the cylinder and the machinery it operates. By preventing overloading, reducing wear and tear, and ensuring compatibility, the overall durability and longevity of the equipment are enhanced, leading to cost savings and reliable performance over time.

By understanding the various aspects of hydraulic cylinders, from their components and types to specifications, inspection, and maintenance, you can make informed decisions in identifying and selecting the right cylinder for your needs. This knowledge ensures optimal performance, efficiency, and durability in your hydraulic systems.

In addition to our skilled sales team, we have 18 technical experts. poocca has rich knowledge and technical strength. Their expertise not only drives our innovation but also ensures our products and services are at the forefront of technological advancement.