Why Proper Hydraulic Valve Flow Adjustment Matters

The Role of Flow Control in System Performance

Hydraulic systems rely on precise flow control to ensure smooth operation, efficiency, and longevity of components. Flow rates directly impact the speed and pressure of actuators, determining how effectively the system performs its intended function. Proper adjustment of hydraulic valve flow ensures that machinery operates at the correct speed, preventing excessive energy consumption or sluggish performance.

Key Signs Your Valve Needs Adjustment

Spotting when a hydraulic valve needs tweaking is vital for steady performance. A frequent sign is uneven actuator motion. Cylinders or motors may move oddly or at varying speeds. This often means the flow is too high or too low for the task. Another clue is unstable system pressure. It can hint that the valve isn’t managing fluid flow well.

Operators might also notice hotter running temperatures. These can come from high flow rates causing heat via fluid friction. Strange noises—like chattering or cavitation sounds—may point to flow imbalance too. Catching these signs early helps avoid bigger breakdowns and pricey fixes.

Step-by-Step Guide to Adjusting Hydraulic Valve Flow

Tools and Safety Precautions You’ll Need

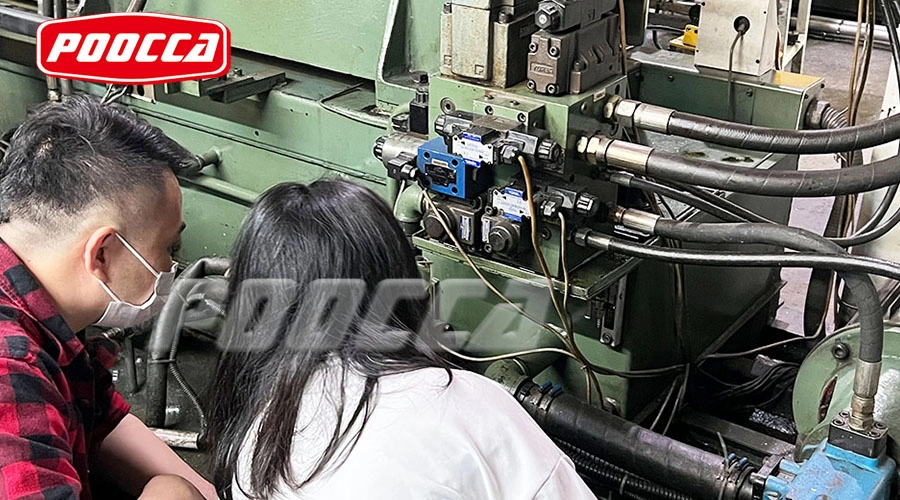

Before tweaking anything, gather the right tools and take safety steps. You’ll need pressure gauges, flow meters, and the maker’s guide for your valve. Flow meters show live fluid movement data. Pressure gauges keep adjustments within safe limits.

Safety comes first with hydraulic systems. Always release system pressure before starting. This avoids risky fluid bursts. Wear gear like safety glasses and gloves to lower injury chances. Also, keep the work area safe and clear of hazards. This prevents mishaps during tweaks.

Locating the Flow Control Mechanism

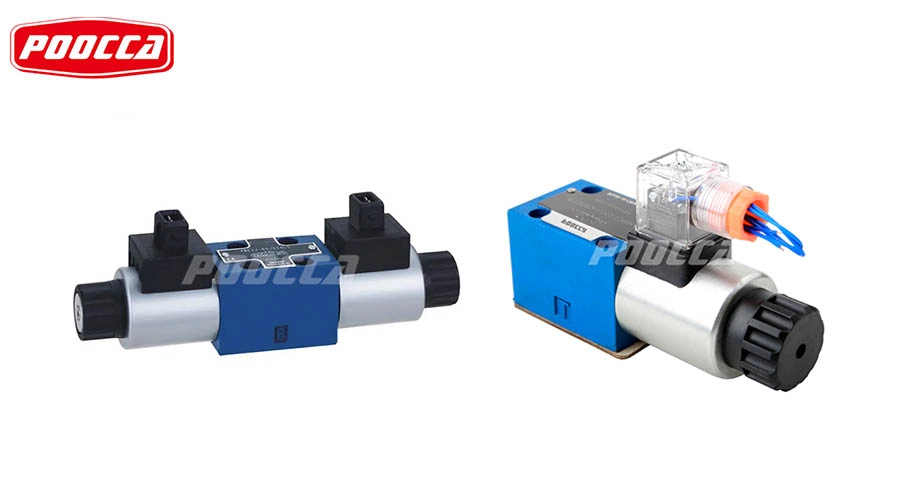

Knowing your hydraulic valve type is crucial to finding the flow control part. Most valves have a screw or knob to adjust fluid passage. These appear on pressure-compensated or non-compensated valves. Each type needs a slightly different method.

Pressure-compensated valves keep flow steady despite pressure shifts. They suit tasks needing consistent output. Non-compensated valves allow more hands-on tuning. They need close watching for stable running. Also, flow valves can be meter-in, meter-out, or bypass setups. Each affects how flow is controlled. Understanding these setups ensures precise tweaks that match system needs.

Fine-Tuning the Flow Rate

To Adjust the Flow on a Hydraulic Valve properly, start with small steps, not big leaps. Set the flow low at first. Then raise it slowly while checking the system’s reaction. Test tweaks under load for a true sense of normal performance.

Live data from gauges and meters confirms adjustments. It keeps flow in the best range. If pressure or heat spikes too much, tweak the valve again. This balances safety and efficiency. Note each change you make. These records help with future upkeep and fixes.

Post-Adjustment Testing and Calibration

After setting the flow, test to ensure system steadiness. Run cycle tests through the system’s full motion range. This checks if tweaks hold up across conditions.

Log all changes made, like valve settings and performance notes. Keeping clear records tracks system trends over time. It eases future upkeep tasks. Regular calibration checks keep flow control sharp for lasting efficiency.

Advanced Tips for Optimizing Hydraulic Flow

Balancing Flow and Pressure for Peak Efficiency

Hydraulic setups face factors like temperature and fluid thickness. These can shift flow tweaks. As heat rises, fluid gets thinner. This may change flow rates. Adjust settings based on temperature shifts to keep top performance.

Overcorrecting is a common error. Too much tweaking can spark new issues, not fix old ones. Fine-tune flow and pressure together. This avoids extra strain on parts.

Troubleshooting Common Adjustment Challenges

Even with good tweaks, problems can pop up. Leaks can mess with flow rates. They make steady output tough. Check seals, fittings, or hoses for wear to fix leaks fast.

Air stuck in the system can cause odd flow too. Bleed the circuit to clear air. This ensures smooth running and stops cavitation harm. If valve noise or chatter lingers after tweaks, check its fit with system pressure and flow needs.

Avoiding Costly Mistakes in Flow Adjustment

Top Errors Beginners Make (And How to Fix Them)

A frequent slip-up is over-tightening adjustment screws. This limits flow, hurting performance and wearing parts faster. Stick to maker specs and use slow tweaks to dodge this.

Misreading how pressure and flow connect is another pitfall. Higher pressure doesn’t always mean more flow. Grasping their link is key for good adjustments.

When to Call a Professional

Many flow tweaks suit operators. But some cases need expert help. Ongoing inefficiencies, stubborn issues, or odd pressure swings may signal deeper trouble. Pros ensure complex systems get proper fixes for best running.

For unique tasks, POOCCA offers custom solutions. These tailored valves boost performance. They’re built for specific flow and pressure needs, ensuring precision in tough jobs.

FAQs About Adjusting Hydraulic Valve Flow

How often should I check my hydraulic valve’s flow settings?

It depends on system use. For heavy industrial jobs, check every three months. This keeps performance sharp and avoids inefficiencies. Lighter setups may need checks twice a year or yearly. Regular monitoring spots issues before they grow costly.

Can I adjust flow without a pressure gauge?

It’s not wise to tweak flow without a gauge. This risks overpressurization, which can harm parts or crash the system. Gauges give live data to keep tweaks safe.

Why does my valve lose calibration after adjustment?

Calibration drift often ties to wear, dirt, or fluid changes. Check seals, fluid state, and valve parts often to hold steady output.

What’s the difference between flow control and pressure control valves?

Flow control valves manage fluid rate and speed for smooth actuator work. Pressure control valves handle force limits. They shield parts from pressure jumps and damage.

Ready to Master Your Hydraulic Systems?

Knowing how to Adjust the Flow on a Hydraulic Valve keeps efficiency high and stops breakdowns. Follow best steps and fixing tips to boost performance. This extends part life too.

For precision solutions, POOCCA offers custom setups for your industry needs. Contact our team to explore advanced valve options built for your tasks.