Starting Out

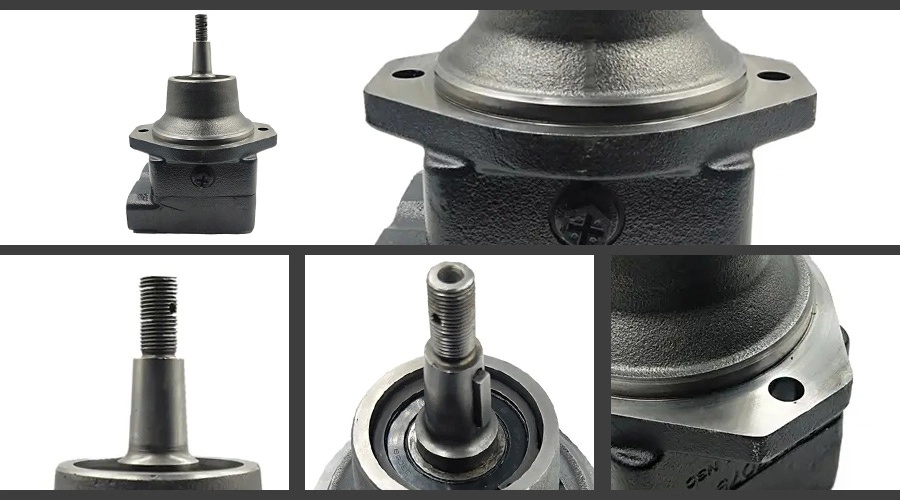

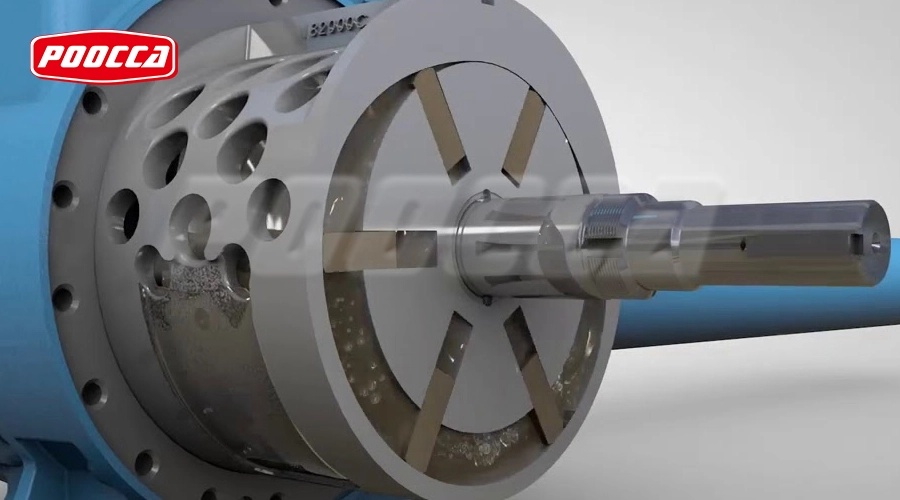

Before testing starts, it’s useful to know what a hydraulic vane motor is. This machine turns liquid force into spinning action. It has a shell, a rotor with flaps, and a port plate. When liquid gets pumped in, it fills spaces between the flaps and shell. This makes the rotor turn.

The setup runs smoothly, gives strong power at slow speeds, and is small. Hydraulic vane motors are used in big machines, mobile gear, and systems that need steady spinning.

Why Test Performance?

Testing a hydraulic vane motor’s performance matters for a few reasons. First, it checks if the motor follows its rules. Second, it spots troubles early. This saves time and effort later. Third, it shares helpful facts to make the motor work better and save energy.

Testing also finds wear before it breaks. This early step cuts downtime and keeps things safe.

Tools Needed

To test a hydraulic vane motor, some simple tools are needed. Here’s what the setup should have:

- Hydraulic Power Unit: Sends liquid under pressure to run the motor.

- Flow Meter: Checks how much liquid flows into the motor.

- Pressure Gauge: Shows pressure at the start and end points.

- Torque Sensor: Tracks the motor’s twisting strength while working.

- Speed Sensor: Measures how fast the shaft spins (RPM).

- Data Acquisition System: Collects all sensor data for review.

These tools give clear info on how the motor works under different loads.

Testing Steps

With tools ready, follow these steps to test the hydraulic vane motor:

Step 1: Set Up the Test Rig

Connect the hydraulic power unit, flow meter, pressure gauge, torque sensor, speed sensor, and data system to the motor. Use the maker’s guide. Make sure all fittings are tight and won’t leak.

Step 2: Prepare the System

Fill the hydraulic power unit with the right liquid. Clear air bubbles by priming the system.

Step 3: Start the Motor

Slowly raise the liquid’s pressure and flow. Wait for the motor to start spinning. Watch sensor readings as it runs.

Step 4: Load Test

Add weight with a dynamometer or load tool. Increase the weight bit by bit. Keep an eye on torque, speed, pressure, and flow.

Step 5: Check Efficiency

- Output Power: Torque × Speed

- Puissance d'entrée: Pressure × Flow

- Efficacité: Output Power ÷ Input Power

Step 6: Look for Leaks

Check the motor and connections for any liquid drips.

Step 7: Speed Test

Change the liquid flow rate while keeping pressure steady. Write down the RPM for each setting.

Step 8: Review Data

Look at the collected numbers. Compare them to the maker’s standards. Check for odd patterns or problems.

This full process shows how the motor performs in all cases.

Common Problems

During tests or use, some issues might show up:

- Weak Torque: Worn flaps or low pressure can cause this.

- Noisy or Shaky Running: Might come from misalignment or cavitation.

- Leaks: Often from broken seals or cracked shells.

- Too Hot: Could be from too much pressure or bad lubrication.

Finding these early helps fix them fast.

Fix Tips

If tests show problems:

- Check the Liquid: Make sure it’s clean and at the right level.

- Look at Seals: Replace any worn or broken seals.

- Clean Port Plate: Remove debris that blocks flow.

- Replace Flaps: Swap out damaged or worn flaps.

- Fix Alignment: Adjust misalignment to stop shaking.

- Check Bearings: Change them if there’s noise or wobble in spinning.

These steps usually get the motor back in shape.

Why Choose POOCCA for Hydraulic Vane Motors?

POOCCA Hydraulic (Shenzhen) Co., Ltd., began in 2006. It has four locations in Hong Kong, Guangdong, Jiangsu, and Zhejiang. With over 26 years in hydraulics, POOCCA is great at making gear pumps, piston pumps, vane pumps—including top-quality hydraulic vane motors—and other parts.

The company’s 8,000-square-meter factories use tools like CNC gear cutters and computer-run testing machines. This ensures every part is made right. POOCCA works with dealers in over 75 countries, like Brazil, Russia, Indonesia, and Mexico. It offers shipping choices to fit schedules.

A team of 18 tech experts helps make custom products. They create solutions for specific needs. From pre-sale help to a 12-month warranty, POOCCA gives full support.

FAQ

What is a hydraulic vane motor?

A hydraulic vane motor is a machine that turns liquid force into spinning power. It has a rotor, flaps, and a shell. Liquid pushes the flaps to make the rotor spin.

What are the main uses of hydraulic vane motors?

They’re used in car systems, big machines, building gear, and power steering. They fit in small spaces and move power well.

How is a hydraulic vane motor different from other hydraulic motors?

Unlike gear or piston motors, hydraulic vane motors run smoother with less noise and shaking. They also handle many liquid types, making them handy.

What are the benefits of hydraulic vane motors?

They offer:

- Smooth and steady running

- Big power in a small size

- Good work in medium to low-pressure tasks

- Quiet running with less noise and shaking

How to care for a hydraulic vane motor?

Check liquid levels and cleanliness often. Keep the motor free of debris. Look at seals for wear. Watch for leaks or odd sounds that might show problems.

What causes performance issues in a hydraulic vane motor?

Issues like weak torque, leaks, getting too hot, or noise may come from dirty liquid, broken seals, misalignment, or worn flaps.