Understanding High Pressure Hydraulic Pumps

What Defines a High Pressure Hydraulic Pump

High pressure hydraulic pumps are super handy for tons of industrial tasks. They give the muscle to move big machines and gear. These pumps are built to whip up and keep strong hydraulic pressure, often past 250 bar. This is crucial for jobs needing lots of push and control.

Unlike low pressure pumps, these pack a way bigger punch. They’re just right for heavy work in places like construction, mining, and factories, where tough power is a must.

Key Components and Operating Principles

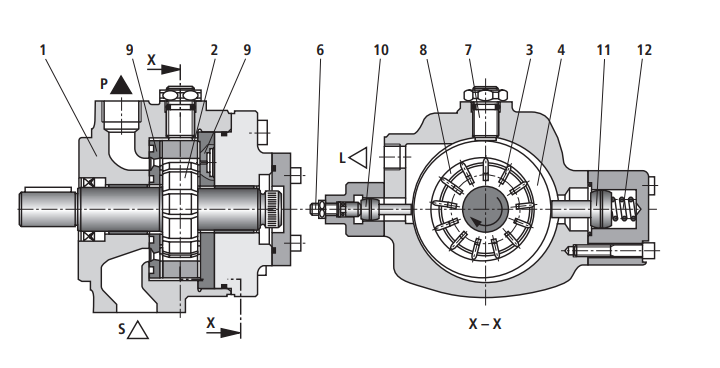

High pressure hydraulic pumps turn mechanical energy into hydraulic energy with moving bits. These parts—like pistons, gears, or vanes—shove fluid through a system at high pressure. The main pieces are:

- Pump housing: Holds all the insides together.

- Drive shaft: Sends energy from the motor.

- Displacement elements: Pistons or gears that push the fluid.

- Seals and valves: Keep pressure locked in and stop leaks.

How well these bits work sets how great the pump performs.

Common Applications Across Industries

These pumps rock in tasks needing precision and strength. They’re used in:

- Construction gear like excavators and bulldozers.

- Factory presses and molding machines.

- Mining for drilling and hauling stuff.

- Farm machines needing strong hydraulic systems.

Their versatility makes them a backbone of modern work.

Overview of Rexroth’s High Pressure Hydraulic Pumps

Rexroth is a big name in hydraulic pumps and systems. They offer a wide bunch of high pressure hydraulic pumps for industrial jobs. Known for nifty engineering, Rexroth crafts products with clever tech to stay solid in rough conditions.

Their lineup has models with special tricks for specific tasks. For instance:

- Le A10VSO Series Axial Piston Variable Pumpgives displacements from 18 to 140 cm³/rev with pressures up to 350 bar.

- Le A8VO Piston Pumphandles displacements from 55 to 200 cm³ with peak pressures up to 400 bar.

- Le A22VG Piston Pumpis built for closed-circuit hydrostatic drives with max pressures up to 420 bar.

These are just a few from Rexroth’s big catalog made for different work needs.

Types of High Pressure Hydraulic Pumps

Rexroth offers several kinds of high pressure hydraulic pumps, each suited for certain jobs:

Pompes à piston axial

Pompes à piston axial tackle high pressure and big flow rates. They use a swash plate design for spot-on flow and pressure control.

Pompes à piston radial

Radial Piston Pumps are awesome for high pressure and low flow rates. Their radial piston setup gives a smooth, steady fluid flow.

Bent Axis Piston Pumps

Bent Axis Piston Pumps handle high pressure and medium flow rates. Their bent axis design keeps them compact and dandy.

Pompes à engrenages

Gear Pumps work with lower pressures and flow rates than other high pressure pumps.

Pompes à mourir

Vane Pumps manage moderate pressures and flow rates. Their simple, reliable design ensures smooth fluid flow.

Each type has unique perks based on system needs like space, efficiency, noise, or cost.

Advantages of Rexroth’s High Pressure Hydraulic Pumps

High pressure hydraulic pumps are key for heavy-duty industrial work. Rexroth’s pumps shine for their quality, dependability, and toughness.

Avantages clés

- Grande efficacité: These pumps save energy, cutting down costs.

- Faibles niveaux de bruit: Their quiet run fits spots where noise is a concern.

- Durability: They’re built sturdy to handle tough settings, keeping downtime and fixes low.

For example, the A10VSO series runs in open circuits with pressures up to 280 bar. The A22VG model offers precise flow control, great for shifting loads.

Choosing the Right Rexroth High Pressure Hydraulic Pump

Picking the best pump means looking at a few key things:

Exigences de débit

Check flow in LPM or GPM to match what the system needs.

Cote de pression

Make sure the pump’s pressure fits the system’s demands.

Pump Type Compatibility

Axial piston pumps are best for high flows. Radial piston pumps suit high pressure with low flows.

Additional Considerations

Think about the fluid’s thickness, operating temperature range, and any environmental factors. Also, check if it works with system parts and fits in the space.

Matching these to Rexroth’s catalog specs, like displacement or circuit type, ensures a swell fit.

Maintenance and Repair

Good care and fixes keep Rexroth’s high pressure hydraulic pumps running great and lasting long.

Key Maintenance Practices

- Check fluid levels and quality often to spot issues early.

- Swap out filters, belts, and other bits when needed.

If repairs come up, use genuine Rexroth parts to keep performance top-notch. Skilled technicians should do the fixes.

POOCCA offers full help, including repair services, advice from 18 tech pros, and tools in their 8,000-square-meter factory.

FAQ

What types of Rexroth high-pressure pumps are available?

Rexroth offers axial piston variable pumps (e.g., A10VSO), bent axis units (e.g., A2F), radial piston units (e.g., RKP), gear pumps, and vane pumps, each fine-tuned for different needs.

How do I ensure my pump operates efficiently?

Regular care keeps reliability and efficiency high, cutting downtime.

What should I do if my pump fails?

Use genuine parts from providers like POOCCA Hydraulics. Their technicians offer repair services with know-how since 1997.

Can I get custom solutions or expedited shipping?

Yes, volume discounts and custom solutions are available for bulk orders. Contact the sales team for specific needs and pricing.

Source Rexroth’s High Pressure Hydraulic Pumps from POOCCA

Hydraulique POOCCA is an authorized distributor giving full access to genuine Rexroth products. They’re a complete hydraulic service company focusing on research, making, fixing, and selling hydraulic pumps. With exports up to US$16 million yearly across 100+ countries, POOCCA ensures quick delivery and tailored tech support for your work needs.Contact POOCCA to send your inquiry today.