Kolbenpumpen serve as the quiet stars of hydraulic setups, driving all sorts of gear from building equipment to exact production lines. As a top piston pump manufacturer and hydraulic pump supplier, POOCCA has dedicated more than 20 years to refining these vital parts.

This detailed guide looks into the workings, layout rules, and actual uses of piston pumps, aiding engineers, buying groups, and repair experts in making smart choices when getting supplies from a reliable piston pump factory.

Whether people pick parts for tough excavators or improve flow in factory automation, grasping piston pump insides stays key for system steadiness and smoothness. Let us jump into the tech that turns these positive displacement giants into must-haves.

What is a Piston Pump and How Does it Work?

Deep down, a piston pump acts as a positive displacement pump that employs back-and-forth pistons to shift fluid accurately. Unlike centrifugal pumps that depend on speed, piston pumps catch a set amount of fluid and push it through the setup—great for high-pressure tasks.

POOCCA’s axialkolbenpumpen, for example, provide up to 42 MPa in models like the A10VSO series, fitting them well for mobile hydraulics. The pump changes spinning motion from a main driver (electric motor or engine) into straight piston shifts. It creates switching suction and release phases.

Components of a Piston Pump

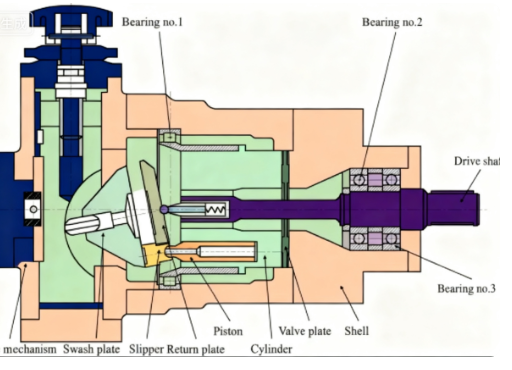

Each strong piston pump depends on finely made pieces operating together smoothly:

Kolben: The active heart, usually built from tough steel or ceramic-covered alloys for lasting strength.

Cylinder Block: A turning drum that holds several pistons (often 7 or 9 in axial types).

Swashplate: Manages piston travel distance; adjustable-angle types allow flow changes.

Valve Plate: Guides fluid path with timing for entry and exit stages.

Drive Shaft: Passes force from the main driver with little bend.

Bearings and Seals: Heavy-duty cylindrical roller bearings and PTFE seals guarantee long life under 350 bar.

The Role of the Cylinder and Piston

The cylinder-piston link decides where smoothness wins or fails. POOCCA shapes cylinder holes to Ra 0.2 μm surface quality, reducing inner leaks even at 400 bar.

In the pull-in phase, the piston pulls back and forms an empty space that sucks fluid via the inlet check valve. During the push phase, the piston moves forward and squeezes fluid toward the outlet valve.

This back-and-forth motion gives steady flow without pulses when many pistons (7–11) align properly.

How a Positive Displacement Pump Operates

Piston pumps fit into the positive displacement group, meaning output links straight to speed and size—free from system pressure. It suits them for:

Measuring exact chemical amounts

Running hydraulic presses

Operating winches and cranes

How Does Hydraulic Load-Sensing and Pressure-Limiting Control Work?

Current hydraulic setups need smart use. POOCCA builds load-sensing (LS) and pressure compensation controls as standard in its A4VSO and A10VSO lines.

Load-Sensing Function

An LS shuttle valve checks pump exit pressure against actuator needs. When load drops, the pump reduces stroke on its own, lowering flow to wait levels (usually 15–20 bar). This stops energy loss and heat rise.

Pressure-Limiting Control

A pilot-run relief part caps top pressure. POOCCA’s electronic pressure control (EPC) option uses ratio solenoids for quick replies in milliseconds, guarding parts during fast blocks.

Interaction Between an Axial-Piston Pump and Control Systems

In variable displacement axial piston pumps, the swashplate angle sets output. POOCCA’s electro-hydraulic control employs a ratio valve to angle the swashplate from electric signals, allowing links with CAN bus setups.

Key Components in a Piston Pump Diagram

Piston Pump Diagram – POOCCA Hydraulic

Drive Shaft: Hardened Cr-Mo steel, dynamically balanced

Swashplate: 0° to 18° variable angle

Piston Shoes: Hydrodynamic bearing design

Cylinder Block: 9 pistons at 40° intervals

Valve Plate: Bronze with pressure-balanced design

Control Piston: For swashplate actuation

How Pump Output and Flow Rate Affect Performance

Basic displacement gets figured as:

Q=π×d2×s×n×z4×60×1000[L/min]Q = \frac{π × d² × s × n × z}{4 × 60 × 1000} [L/min]Q=4×60×1000π×d2×s×n×z[L/min]

Where:

d = piston diameter (mm)

s = stroke length (mm)

n = speed (RPM)

z = number of pistons

Factors Influencing Performance

Geschwindigkeit: Faster RPM raises flow but risks empty bubbles above 3000 RPM

Flüssigkeitsviskosität: ISO VG46 best; too thick cuts efficiency

Temperature: 40–60°C perfect working range

Common Issues with Piston Pumps and Troubleshooting

| Symptom | Cause | POOCCA Solution |

| Pressure fluctuations | Worn valve plate | Replace with POOCCA OEM part (P/N: 123456) |

| Noise >85 dB | Kavitation | Install POOCCA anti-cavitation check valve |

| Leakage | Seal failure | Upgrade to POOCCA Viton seals for 120°C operation |

| Reduced flow | Internal wear | Rebuild kit with DLC-coated pistons |

Frequently Asked Questions (FAQ)

What is the difference between an axial piston pump and a radial piston pump?

Axial piston pumps use pistons arranged parallel to the drive shaft and offer compact size with high efficiency. Radial piston pumps have pistons arranged in a circular pattern and are typically used for extremely high pressures.

How do I know if my piston pump is failing?

Common signs include abnormal noise, pressure fluctuations, overheating, internal leakage, and reduced flow. Early detection can prevent major system damage.

Why is my hydraulic piston pump making noise?

Noise is usually caused by cavitation, aeration, insufficient inlet pressure, or worn internal components. Checking oil level, viscosity, and inlet conditions is essential.

How often should a piston pump be serviced or rebuilt?

Most pumps require inspection every 2,000–4,000 operating hours, with full rebuilds depending on load, oil condition, and system cleanliness.

What hydraulic oil is suitable for piston pumps?

ISO VG32 or VG46 oils are commonly recommended. Oil with the correct viscosity and good anti-wear properties helps maintain efficiency and reduce wear.

How much pressure can a piston pump handle?

Many industrial piston pumps operate between 250–420 bar. Always check the rated pressure to ensure safe and stable operation.

What causes cavitation in piston pumps?

Cavitation typically results from low inlet pressure, clogged filters, high oil viscosity, or excessive pump speed. It can quickly damage pistons and valve plates.

Can a piston pump run with biodegradable or fire-resistant hydraulic fluids?

Yes, as long as compatible seals and materials are used. Some fluids may require special elastomers or coatings to ensure long-term reliability.

Why is my piston pump losing flow or pressure?

Possible causes include internal wear, contaminated oil, air ingress, clogged suction lines, or poor temperature conditions.

What are the advantages of a variable displacement piston pump?

They automatically adjust flow based on system demand, improving efficiency, saving energy, and reducing heat generation.

How do I choose the right piston pump for my hydraulic system?

Consider displacement, pressure rating, speed limits, control type (LS, pressure-compensated), oil compatibility, and working environment.

Partner with POOCCA – Your Trusted Piston Pump Manufacturer & Supplier

As a high-level piston pump factory with ISO 9001:2015 certification, POOCCA supplies finely built solutions trusted by Caterpillar, Komatsu, and Sany OEMs around the world.

Why Choose POOCCA as Your Hydraulic Pump Supplier?

20+ years of manufacturing expertise

500,000+ units produced annually

Global warehouse network (China, USA, Germany)

Free 3D models & datasheets for integration

Dedicated support with technical account managers

Ready to boost hydraulic systems? Kontakt POOCCA’s engineering team for custom piston pump solutions, bulk pricing, or on-site system checks.

sales@kamchau.com | +86 18927498997

Get a Quote in 12 Hours

POOCCA – Powering Your Success with Precision Hydraulics