Einführung

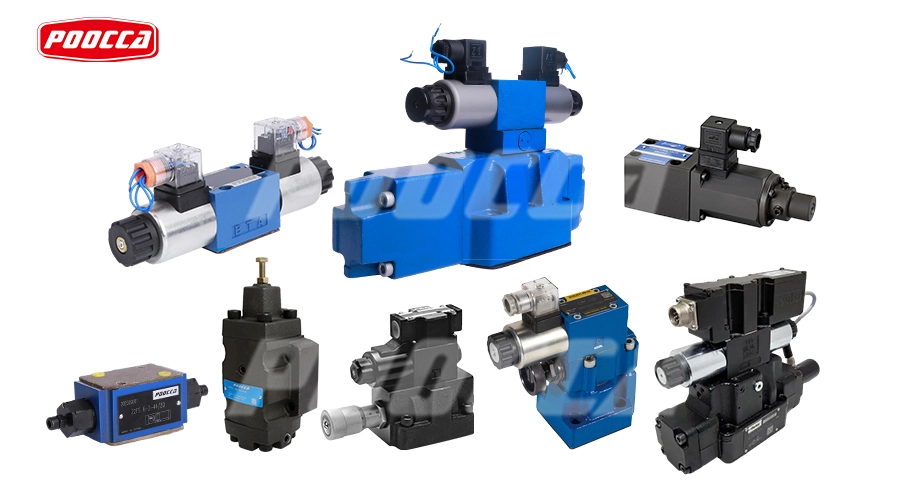

Hydraulikventile are super cool parts in fluid power systems. Commonly used hydraulic valves are: hydraulic directional control valve, hydraulic pressure control valve, hydraulic flow control valveThey handle pressure, flow rate, and direction of hydraulic fluids. These awesome gadgets pop up in lots of places like construction, farming, factories, and material handling. What’s the deal with a hydraulic relief valve? It keeps systems safe by letting out extra fluid when pressure gets too high. Knowing all about hydraulic valves is crucial for picking the best one for a task.

Hydraulik Richtungssteuerventile

As the name spills, richtungssteuerventile guide fluid flow in a system. They choose where hydraulic fluid travels by opening or shutting paths in a circuit. These valves can kick off, halt, or flip the flow’s direction.

Their job hinges on how many ports and spool positions they have. A popular kind is the 4/3-way valve. It’s got four working ports and three spool spots for fancy moves. Simpler ones include 2-way and 3-way directional control valves. The 2-way valve is the easiest, with just two ports: inlet and outlet. A 3-way valve has three ports: inlet, outlet, and exhaust.

These valves come in cool styles, like hand-operated levers or solenoid-driven designs. For instance, POOCCA has models like the P40 P80 P120 series. These boast tidy builds and solid performance. Flow rates reach 40, 80, or 120 liters. Pressures hit up to 315 bar for P, 50 bar for T, and 300 bar for A-B. Check out POOCCA’s valves.

Hydraulikdruckregelventil

Pressure control valves are key to keeping hydraulic systems safe and steady. They’re the top pick for managing pressure. Types include relief valves, reducing valves, sequence valves, counterbalance valves, and unloading valves.

Their big task is to keep pressure just right by releasing extra fluid when needed. Hydraulic pressure control valves stop leaks and keep pipes or tubes from bursting. They dodge overpressure that could wreck gear or cause trouble.

These valves are in nearly every hydraulic system. They tackle jobs like keeping pressure safe or setting up step-by-step actions in multi-stage systems.

POOCCA offers top-quality parts that match brands like Rexroth, Parker, Yuken, Vickers, and more. Compatible brands include Shimadzu, Danfoss, Marzocchi, and Casappa, guaranteeing great quality for hydraulic needs.

Hydraulic Flow Control Valves

Flow control is super important for managing actuator speed and saving energy in hydraulic systems. Flow control valves tweak how fast an actuator moves by adjusting the flow rate. This changes not just speed but also how smoothly energy flows through the system.

Flow rate decides how fast energy moves at a certain pressure. By fine-tuning flow rates, these valves make motion smoother and cut wear on parts.

They also keep an eye on pressure changes and stop flow from hitting other components. These valves come in forms like needle valves or variable orifice types, depending on the task.

POOCCA’s huge product lineup covers everything from tiny machines to big industrial setups. Their solutions ensure awesome performance with spot-on flow control.

Not sure which valve to choose?

Choosing between directional control valves, pressure regulators, or flow controllers can be tough without tech smarts. How does one pick the right hydraulic valve for a job? Think about flow, pressure, and control needs to make a wise choice.

Expert help makes a huge difference. POOCCA Hydraulics (Shenzhen) Co., Ltd. brings over 20 years of know-how. Started in 1997, the company works from Hong Kong to Jiangsu province.

They’ve got nifty manufacturing tools, like CNC gear grinders and auto inspection systems. These keep quality high across over 1,600 products, including pumps, motors, and hydraulic accessories.

A hardworking team of over 70 sales folks and 18 tech wizards delivers cool hydraulic solutions. Their skills make sure every job gets the perfect valve, no matter the setup.

POOCCA: TOP China Hydraulic Valves Manufacturer

POOCCA shines as a top maker of high-performance hydraulic products in China. The company dives into research, development, manufacturing, maintenance, and sales of hydraulic pumps, motors, valves, and parts.

Their factory covers over 8,000 square meters, with 6,000 square meters for production. They serve over 100 countries, with exports hitting US$16 million yearly, showing a strong global reach.

Whether standard parts or custom fixes are needed, POOCCA crafts tailored hydraulic solutions. Their one-stop service covers pre-sales tips, tech know-how, custom advice, quick replies, and after-sales help like repairs and warranties. This keeps customers happy for the long run. Explore POOCCA’s stuff.

FAQ

1. What is the function of a hydraulic pressure relief valve, and how does it prevent system failure?

A pressure relief valve keeps hydraulic systems safe from too much pressure. It sends extra fluid back to the tank when pressure hits a set limit. This stops pipes from bursting, seals from breaking, or pumps from overloading, especially during startup or when actuators stall.

2. How does one select the correct directional control valve for a double-acting cylinder?

For a double-acting cylinder, a 4/3-way directional control valve is usually best. It handles extension, retraction, and a neutral position. Selection should check spool type (open or closed center), actuator flow rate, operating pressure, and whether it’s manual, electric, or hydraulic actuation.

3. Can hydraulic flow control valves regulate speed in both directions?

Yup, but it depends on the valve. A bi-directional flow control valve handles flow both ways. Standard one-way valves limit flow in one direction and allow free return via a check valve. Picking the right one ensures steady actuator speed in any direction.

4. What are the main causes of internal leakage in hydraulic valves, and how can it be prevented?

Internal leakage often comes from worn seals, spool erosion, or dirt in the system. This can cause slow actuator response or pressure drops. To stop it, use clean hydraulic fluid, keep filtration levels right, and choose valves with precision-ground parts for tight sealing.