Hydraulikmotoren are key parts in fluid power setups. They turn liquid energy into spinning motion to run machines in fields like building, farming, mining, and factories. These motors control force, speed, and work quality, affecting how well machines run and how much they produce. The main kinds—radial piston hydraulic motor, axial piston hydraulic motor, gear hydraulic motor, and vane hydraulic motor—each have unique builds and traits suited for different jobs and conditions.

1. Radial Piston Hydraulic Motor

Der radial piston hydraulic motor shines in tasks needing strong force at low speeds. Its sturdy build has pistons set in a circle around a main shaft.

1.1 Operating Principle

Pressurized oil flows into piston bases through openings in a fixed shaft. This pushes pistons against an off-center stator. The force splits into parts, creating spin on the cylinder block. The spin strength, or torque, follows this formula:

T = (p × d² × sinθ) / 4

Here, p is pressure, d is piston size, and θ is the force angle. Many pistons (7–11) work together for steady, smooth spinning through an end shaft.

1.2 Performance and Applications

This motor handles pressures up to 400 bar and forces over 50,000 N·m. It starts with 90% efficiency and keeps 92% of its fluid use effective. You’ll find it in winches, excavator tracks, and molding machines. The Rexroth A2FM series (5–1000 cc/rev, 450 bar peak) pairs with adjustable pumps for steady power in boats and digging equipment.

1.3 Advantages and Limitations

Its many pistons cut speed wobbles, perfect for long-running tasks. But, shaping the stator is tricky and costly. Also, dirty fluid can wear pistons, so it needs clean ISO 18/16/13 fluid to stay safe.

2. Axial Piston Hydraulic Motor

The axial piston hydraulic motor has pistons lined up along the shaft. Its small size and adjustable build allow flexible control of force and speed.

2.1 Mechanism and Operation

Oil moves through a plate into piston holes, pushing pistons against a tilted swashplate. The force splits into straight and side parts, with the side part spinning the shaft counterclockwise. Changing the swashplate angle α adjusts the motor’s output, giving up to 5000 N·m of force and a 1:10 speed range.

2.2 Efficiency and Use Cases

With 92% mechanical efficiency and 94% fluid efficiency at 350–420 bar, this motor fits high-power jobs like tractor drives and factory conveyors. The Parker F11/F12 series (18–130 cc/rev, 3600 rpm) works great in plastic-making due to fast spinning.

2.3 Challenges

Dirt can scratch pistons, harming swashplate contact. Pressure changes also make noise. It needs clean ISO 18/16/13 fluid and regular checks on slippers for upkeep.

3. Gear Hydraulic Motor

The gear hydraulic motor is simple and cheap. It uses meshing gears to spin, best for medium tasks needing fast speeds.

3.1 Design and Function

Equal ports let it spin both ways. Extra ports drain bearing oil. Pressurized fluid in gear gaps drives spinning. The force depends on size (1–200 cc/rev) and pressure (up to 250 bar). More gear teeth (12–16) cut force wobble by about 5–10%.

3.2 Applications and Efficiency

It runs at 85–90% efficiency between 500–3000 rpm, powering fans and grain augers. The Marzocchi GHM series (0.25–135 cc/rev) saves 20–30% cost compared to piston types and lasts over 10,000 hours.

3.3 Limitations

Weak seals cause leaks at low speeds, limiting force to 800–1000 N·m and fluid efficiency to 80% under high pressure. This makes it unfit for precise jobs. Gear noise (80–90 dB) can be reduced with helical gears.

4. Vane Hydraulic Motor

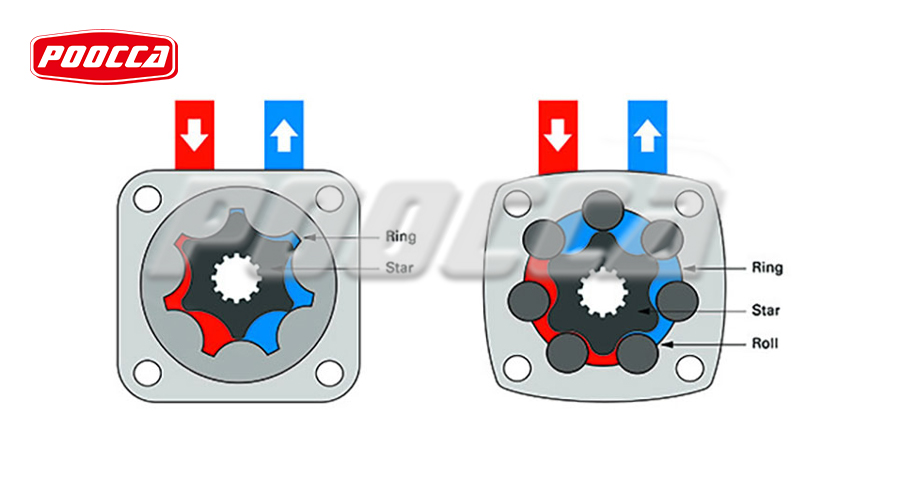

The vane hydraulic motor uses sliding vanes in rotor slots to make chambers. It gives smooth force for fast, medium-strength tasks.

4.1 Operational Mechanics

Pressure differences push the rotor unevenly, creating spin. The force ties to size (5–500 cc/rev) and pressure (up to 210 bar). Vane setup and valves allow two-way spinning, while springs keep seals tight.

4.2 Performance Characteristics

With almost no wobble and 88–92% efficiency, it hits 6000 rpm, great for tools and steering. The Denison T6 series (torques to 1500 N·m) stays quiet (<75 dB) under normal loads.

4.3 Constraints

Leaks at low speeds (below 500 rpm) hurt stability, needing back-pressure fixes. Vane wear requires clean ISO 16/14/11 fluid, and stator shaping raises costs.

5. Similarities Among Types of Hydraulic Motors

All hydraulic motors use a positive-displacement design, turning pressurized fluid into spinning work. They can spin both ways with balanced ports. Force grows with pressure and size:

T = (ΔP × Vd) / (2π)

Speed depends on fluid flow:

Q = (Vd × n) / 1000

Efficiencies range from 85–95%. Clean ISO 18/16/13 fluid reduces fluid and friction losses.

6. Differences Among Hydraulic Motor Types

Each motor’s build shapes its use. Radial piston hydraulic motors and axial piston hydraulic motors give big force (10,000+ N·m) and high pressure (400+ bar) for tough jobs, but their adjustable designs add complexity. Gear hydraulic motors focus on fast speeds (3000+ rpm) and low cost for smaller forces (<1000 N·m), though efficiency drops (80–85%). Vane hydraulic motors provide smooth, fast output (6000 rpm) but struggle at low speeds.

| Aspect | Radial Piston Hydraulic Motor | Axial Piston Hydraulic Motor | Gear Hydraulic Motor | Vane Hydraulic Motor |

| Torque Range | Up to 50,000 N·m | Up to 5,000 N·m | Up to 1,000 N·m | Up to 1,500 N·m |

| Speed Range | Up to 500 rpm | Up to 4,000 rpm | Up to 3,000 rpm | Up to 6,000 rpm |

| Druckbewertung | 400 bar | 350–420 bar | 250 bar | 210 bar |

| Effizienz | 90–95% | 92–94% | 85–90% | 88–92% |

| Key Advantage | Hohes Startdrehmoment | Variable displacement | Low cost, simplicity | Smooth, low noise |

| Key Limitation | High cost, complexity | Noise, contamination | Leakage, ripple | Low-speed instability |

| Anwendungen | Winches, tracks | Transmissions, conveyors | Fans, augers | Steering, metering |

These differences guide choices: piston motors for heavy tasks, gear motors for budget jobs, and vane motors for precise, fast work.

7. Conclusion

Each hydraulic motor’s design affects how well it works in fluid power systems. Radial piston hydraulic motors and axial piston hydraulic motors handle big forces for tough jobs. Gear hydraulic motors suit budget-friendly tasks, and vane hydraulic motors excel in fast, precise work. Matching motors to system needs—like using radial piston hydraulic motors with steady-pressure pumps—boosts work rates above 85%. New materials, like self-sliding vane composites, improve efficiency and promise better machines ahead.

FAQ

What factors influence the selection of hydraulic motor types for industrial applications? Choices depend on force, speed, pressure, efficiency, and work conditions. Radial piston hydraulic motors fit high-force, slow tasks like winches. Vane hydraulic motors work for fast, low-force jobs like conveyor controls.

How do efficiency losses vary across types of hydraulic motors? Gear hydraulic motors lose efficiency (below 85%) due to leaks at low speeds. Piston motors keep 90%+ efficiency with precise parts. Vane motors hit 88–92% efficiency, with springs reducing tip leaks.

What maintenance extends the life of radial piston hydraulic motors in mining? Clean ISO 18/16/13 fluid, low drain pressure (below 2 bar), piston checks every three months, and yearly bearing grease keep 95% efficiency and over 15,000 hours of life.

Can gear hydraulic motors support bidirectional rotation without modification? Balanced ports allow two-way spinning. But, leaks raise force wobble by 5–10%. Helical gears help balance performance.

When do axial piston hydraulic motors outperform vane hydraulic motors in agriculture? Axial piston hydraulic motors shine in changing-load drives, giving 20% more power. Vane motors work better in quiet, low-wobble steering systems.

Partner with POOCCA for Precision Hydraulic Motor Solutions

POOCCA Hydraulics (Shenzhen) Co., Ltd., started in 2006, offers strong hydraulic motor types, including radial piston hydraulic motors (Rexroth A2FM, 1000 cc/rev, 450 bar), gear hydraulic motors (Marzocchi GHM, 0.25–135 cc/rev), and vane hydraulic motors (Denison T6, 210 bar). Certified with ISO 9001, CE, and RoHS, these motors reach 95% efficiency and forces up to 50,000 N·m for building, farming, and mining.

With over USD 16 million in exports to 120+ countries, POOCCA provides custom OEM/ODM options, 12-month warranties, and 5–7 day delivery. Wenden Sie sich an Poocca bei sales@kamchau.com.