In industrial factories, hydraulic presses play a key role in jobs like metal shaping, putting parts together, molding, and extrusion work. These machines need accurate hydraulic systems to create huge force for large-scale production. Right at the heart of every good hydraulic press sits the hydraulic pump. This part decides how well the whole system works, how nice the finished pieces look, and how long everything lasts.

Picking the right المضخة الهيدروليكية helps everything run smoothly on the press floor. It cuts downtime and raises output in tough places such as car part making, aircraft building, and big equipment assembly.

What Is a Hydraulic Pump and Why Does It Matter?

A hydraulic pump acts as the main power source inside a hydraulic press system. It turns mechanical power, usually from an electric motor or engine, into hydraulic energy by pushing fluid around. That energy moves the cylinders or pistons that press down on the workpiece with exact force. Tasks like deep drawing, punching holes, or compression molding become possible. In press work, where force can reach hundreds of tons, the pump must keep steady flow and pressure. This directly affects how fast each cycle runs, how accurate the parts come out, and how much electricity the machine uses.

A good pump does more than just work well right now. Bad pumps create too much heat, ruin the fluid quickly, and wear out seals and valves fast. That leads to expensive fixes and stopped production lines. On the other hand, the right pump makes the system react quicker. Presses can then handle changing loads without trouble.

Types of Hydraulic Pumps for Press Machines

Gear Pumps: Affordable and Simple

مضخات التروس work with two gears that lock together. They trap fluid and push it forward. This simple setup works great for low or medium pressure jobs. Their strong outside design handles dirty fluid well, which often happens in rough press areas like building material forming. Displacement usually stays between 1 and 100 cc/rev. Pressure can reach up to 250 bar. These pumps shine in short work cycles, for example, small batch jobs in local workshops.

They cost less because they only have a few parts: gears, housin

g, and shafts. Repairs stay easy and cheap. Most shops can replace seals themselves. That helps companies that watch every dollar. Still, fixed displacement means they cannot change output easily. Energy gets wasted when the load keeps changing. They also make noise, often 70-80 dB, so some factories need sound covers. Even with those limits, gear pumps rule in basic presses. They reach over 90% efficiency at normal speed and often last more than 50,000 hours.

Vane Pumps: Quieter and More Efficient

مضخات العرض use sliding blades inside a rotor. The blades move in and out, making chambers grow and shrink. This gives smooth, steady flow with almost no pulsing. Noise drops below 65 dB most of the time. That makes them perfect for city factories with strict noise rules. Efficiency stays between 85-92%. Even pressure spread reduces wear on cylinders during long runs.

You can buy fixed or variable displacement versions. They handle up to 175 bar and flow from 5-200 L/min. Medium-duty presses for plastic molding or sheet metal bending love them. The smart design fixes small wear by itself, so service comes only after 10,000 hours. They work with many fluids, even synthetic oils for presses hotter than 80°C. They cost 20-30% more than gear pumps at first, but less shaking means fewer stops. Return on investment turns positive fast in lines that need accuracy.

Piston Pumps: High-Performance and Durable

مضخات المكبس, both axial and radial types, use back-and-forth pistons. They reach very high pressure, often 350-420 bar, and big flows up to 500 L/min. Heavy-duty forging and extrusion presses pick them most. Axial style keeps pistons in line with the shaft for small size. Radial style gives extra strength against sudden shocks.

Strong build comes from swashplate or bent-axis parts. These allow variable displacement from 0-100% without wasting fluid. Energy stays low even when load changes a lot, like in car frame assembly lines. Efficiency hits 95%. Volumetric efficiency stays above 98%, so almost no fluid slips past. They cost up to 50% more than vane pumps, yet they run over 20,000 hours with little care. That pays off in factories running around the clock. Modern units add electronic controls. Those can raise output by 25% on automatic lines.

How to Match a Hydraulic Pump to Your Press

Finding the perfect pump for a press needs careful steps. Technical numbers and real shop limits must balance for the best result.

Step 1: Understand Your Press Requirements

Check basic specs first: tonnage (for example 50-500 tons), stroke length, and speed. A 200-ton press shaping aluminum sheets may need 20-50 L/min at 250 bar. Use force = pressure × area to calculate. Too big a pump causes cavitation. Too small one makes the press stop. Look at the press data sheet. Add 10-15% extra for sudden heavy loads.

Step 2: Consider the Application Type

Match the pump to the job. Stamping likes fast vane pumps. Deep drawing wants steady pressure from piston pumps. In multi-step presses for composite parts, variable displacement keeps force even. That stops defects from uneven pressure.

Step 3: Check Compatibility with Your Hydraulic System

Make sure mounting fits (SAE flanges), shaft matches, and tank connects properly. Pump speed (1500-3000 RPM) must work with the motor. When replacing old parts, run CFD tests so long pipes over 10m stay smooth.

Step 4: Evaluate Energy Efficiency

Choose pumps with IE3 motors and smart controls. They cut power use by 20-40%. Full life-cycle checks show piston pumps win on heavy schedules. Lower electric bills pay back the price fast.

Step 5: Think About Maintenance and Availability

Pick pumps easy to take apart with parts sold worldwide. Check everything once a year following ISO 4413 rules. Change filters every 500 hours. Local stock means fast repair and no long waits.

Common Mistakes to Avoid When Choosing a Hydraulic Pump

Skipping common errors saves money and keeps the line running.

Choosing Based Only on Price

Cheap gear pumps often break under constant heavy work. Total cost can triple from repairs. Better look at full ownership cost. Mid-range pumps with MTBF over 15,000 hours usually win.

Ignoring Flow and Pressure Needs

Wrong size starves the system. Accuracy drops and bad parts rise. Test real loads with dynamometers. That stops 10-15% efficiency loss.

Not Considering Future Upgrades

Scalable piston pumps grow with the factory. Adding servo controls later stays easy. Fixed cheap pumps make upgrades 30% more expensive.

الأسئلة الشائعة

What’s the best type of hydraulic pump for a 100-ton press? For a 100-ton press running all day, a piston pump works best. It handles up to 350 bar easily and adjusts flow for different loads. The press stays cool and steady.

How do I calculate the required flow rate for my hydraulic pump? Find cylinder volume first (area × stroke length). Multiply by wanted speed in inches per minute. Divide by 231 to get gallons per minute (GPM). Add 20% extra for losses.

Can I upgrade my press by just changing the hydraulic pump? Yes, a new pump alone often boosts speed and saves power, as long as valves and cylinders match. Variable displacement models can cut cycle time by 15-25%.

How often should I maintain my hydraulic pump? Check it every 500-1,000 running hours. Test fluid, look at seals, and measure dirt level. This keeps it healthy and meets ISO cleanliness rules.

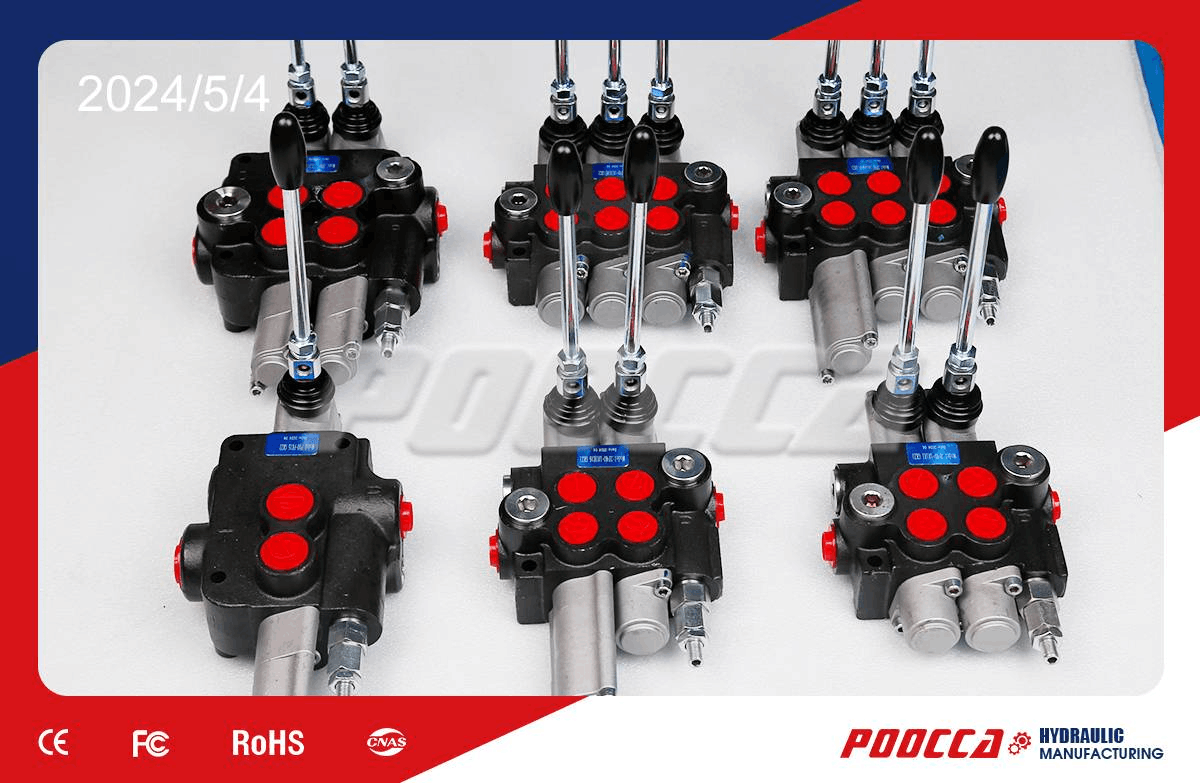

Partner with Leading Manufacturers and Suppliers for Reliable Hydraulic Pump Solutions

Factories that want strong, efficient hydraulic pumps for press work should team up with trusted manufacturers. Experienced companies offer OEM-quality parts at good prices. With more than 18 years in research, building, and worldwide shipping, POOCCA stands as a top manufacturer and wholesale supplier of gear, vane, and piston pumps. ISO certifications and a 12-month warranty back every unit. POOCCA ships to over 120 countries and moves more than $16 million in goods each year. Custom solutions help presses run better and faster. Contact POOCCA now for quotes, free samples, or expert advice. Reliable hydraulic power starts here.