In today’s hydraulic and fluid-power setups, مضخات التروس stay among the most common kinds of positive displacement pumps. They bring plenty of strong points, yet also come with some drawbacks that engineers, buying groups, and system builders need to grasp.

مقدمة

A gear pump works as a turning pump that relies on the shift in work space made between linking gears to push or boost liquid. Two gears, closed inside a pump shell and front & rear lids, create two spaces. As the gears spin, the space on the side where the gears separate grows larger. This makes a suction and pulls in liquid. On the other side, where the gears link, the space gets smaller. This pushes the liquid into the exit line. The intake and release spaces stay apart by the linking line. The exit pressure of the gear pump comes fully from the block at the pump’s outlet. It does not use a separate squeeze room.

مزايا مضخات التروس

Here are some main good points of gear pumps:

Simple Design and Construction

Gear pumps feature fewer moving pieces than more tricky pumps. This makes them fairly simple to build, keep up, and fix.

كفاءة عالية

Since the linking gears move fluid in a closed space, gear pumps deliver steady flow and pressure with little inner leak (slippage) if built and kept right.

المتانة وطول العمر

Gear pumps prove tough. As the manufacturer POOCCA points out, their gear pumps get made for many kinds of fluids, pressures, and factory tasks, with care to parts and cutting.

القدرة على الانتعاش الذاتي

Many gear pumps manage priming by themselves. That means they draw fluid into the pump without needing to fill first. This eases some setup plans.

Constant Output (Low Pulsation)

Gear pumps give a stable, almost steady flow instead of a jumping output. This helps when even flow matters for exact tasks.

Wide Range of Applications

Gear pumps fit many uses and appear in various fields like automotive, chemical, food & beverage, hydraulics, construction equipment, agriculture, and others. For instance, POOCCA provides gear pumps for excavators, dump trucks, agricultural machinery, and other heavy-industry gear.

Compact Size

Since the shape stays fairly basic, gear pumps can stay small and fit into setups where room stays tight.

Disadvantages of Gear Pumps

Even with their good sides, gear pumps hold limits that call for thought:

Limited to Lower Viscosity & Clean Fluids

Gear pumps do not suit very thick fluids well. The extra cut and slower move can cause more inner leak, greater wear, and lower output.

Not Suitable for Abrasive or Highly Corrosive Fluids

If hard bits or rough grains sit in the fluid, the linking gears and inner faces can wear fast. This cuts service time. Also, very harsh fluids may harm parts.

Limited Pressure Range Compared to Some Other Pump Types

Though gear pumps manage medium high pressures, they cannot always match piston pumps or multi-stage centrifugal pumps for super-high pressure tasks.

Noise and Wear Over Time

Based on build and parts, gear pumps can make more sound than vane pumps, for example. Inner wear (bearing, gear tooth, housing gaps) over time can lower work and raise leak.

Fixed Flow Rate (unless equipped with variable controls)

Many basic gear pumps offer a set move per turn. So system change (varying flow) might need extra controls or another pump style.

Potential for Cavitation or Shear Damage

In some tasks with easy-boil fluids or fluid holding air/gas, gear pumps may face more risk of cavitation or gas catch. This can shorten life and cut work.

Maintenance Needs

Though basic in build, gear pumps still need proper care. This includes watching wear, gaps, oiling, fluid purity to keep best work and stop early break.

Types of Gear Pumps & Specific Considerations

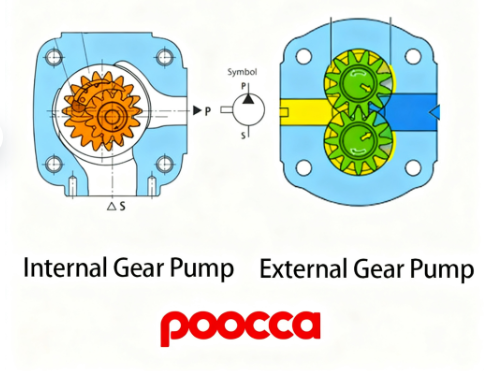

Since the pump build sways both good and bad points, it helps to note two common kinds:

مضخات التروس الخارجية

In an مضخة التروس الخارجية, two outer gears link with each other and the shell. This forms the pumping spaces. Good points include easier build, less weight, smaller size, and lower cost. These fit low- to medium-pressure tasks (like machine tool oiling). Bad points include more inner leak, harder bearing load (uneven forces), higher sound, and jump.

مضخات التروس الداخلية

In an مضخة التروس الداخلية, an outer rotor and an inner rotor link inside the shell. This forms the fluid move space. Good points include tighter build, smaller size, less weight, less slide touch, and lower wear. They also cut jump and sound compared to external gear pumps. Yet, the tooth shape stays more tricky. Cutting exactness stays higher (so cost rises).

How to Choose a Gear Pump – Practical Tips

When picking a gear pump for factory use, think about these points:

Fluid traits: thickness, heat, bits of rough or solids, harshness. Gear pumps work best with clean, medium-thickness fluids.

Needed flow rate and pressure: Look at move amount, RPM, volume output. For very high pressure or much changing flow, other pump kinds might work better.

Noise and jump allowance: If the setup hates sound or needs very even flow, an internal gear pump or other low-jump build may suit more.

Care and wear outlook: Think of the setting (like hard construction vs. clean making), ease of fixing parts, spare stock.

Fit and OEM parts: If swapping old gear, check shape-fit and work match. POOCCA, for example, supplies gear pumps that fit with brands like Rexroth, Parker, Danfoss, Marzocchi.

Cost vs Lifecycle: A lower-cost pump might work at first. But if trust and long time matter much, spending on better parts/build (like internal gear, exact cutting) may return value.

Custom needs: If the task stays special (odd size, link ports, fluid kind), pick a supplier who backs OEM/ODM changes.

Warranty and help: Make sure the supplier gives a warranty and tech aid.

FAQ

Q1. What is the difference between an external gear pump and an internal gear pump?

A: External gear pumps use two external gears meshing with each other. They stay simpler and cheaper but may hold higher inner leak and more sound. Internal gear pumps use one outer rotor and one inner rotor meshing inside the housing; they give smoother flow, less wear and lower sound, but stay more tricky and costly.

Q2. Can gear pumps handle high-viscosity fluids?

A: Gear pumps manage medium thickness, but work and time may drop with very thick fluids. More wear, leak and lower output prove common problems.

Q3. Are gear pumps suitable for abrasive or particle-containing fluids?

A: Generally no—gear pumps suit clean fluids better. Grains and rough can harm gear teeth and inner faces, causing faster wear and shorter span.

Q4. How important is fluid cleanliness for gear pumps?

A: Very key. Dirt cuts output, raises wear and leads to early stop. A strong filter and care plan stays vital for long life.

Q5. How can I ensure the gear pump I buy is reliable?

A: Pick a manufacturer with deep know-how, good cutting and test sites, clear warranty/help, and fit with known brands. For instance, POOCCA states they hold more than 20 years of experience, 12 000 m² factory space, CNC equipment, and products shipped worldwide.

Q6. Can I get custom gear pump solutions (special size, porting, branding)?

A: Yes—many current makers offer ODM/OEM services. For example, POOCCA offers custom specification, nameplate and packaging options.

Ready to source high-quality gear pumps for your manufacturing line or hydraulic system?

As a leading manufacturer and wholesale supplier, POOCCA offers a full range of gear pumps (both external and internal), compatible with major brands, with factory direct pricing, fast delivery, and 12-month quality guarantee. Contact POOCCA today to discuss your exact requirements—whether you need standard models or customized solutions—for reliable and efficient hydraulic performance.

Contact POOCCA now to request a quote, share your system specs, or set up an OEM/ODM arrangement:+86 18927498997 sales@kamchau.com

Let us partner with you to optimise your hydraulic system and reduce total cost of ownership.