فهم مضخات التروس الداخلية: نظرة عامة

جزء لا يتجزأ من مجموعة واسعة من الصناعات ، مضخات التروس الداخلية من المتوقع أن يشهد توسعًا كبيرًا في السوق في السنوات القادمة. كشفت دراسة أجراها رؤى السوق المستقبلية (FMI) أن مضخة التروس الداخلية احتفظ السوق بقيمة 529.1 مليون دولار أمريكي في عام 2023 ومن المتوقع أن يرتفع بمعدل نمو سنوي مركب (cagr) 4.2 ٪ طوال فترة التنبؤ. من المقرر أنه بحلول عام 2034 ، يمكن أن يتصاعد هذا السوق إلى قيمة تقريبية بقيمة 857.2 مليون دولار - دليل مؤشر على زيادة الطلب بشكل كبير وتصعيد التبني.

ما هي مضخات التروس؟

في صميمهم ، مضخات التروس الاستفادة من متشابك التروس لتحريك السائل من مكان إلى آخر داخل نظام هيدروليكي. تتمثل الوظيفة الأساسية لهذه التروس في إنشاء شفط في منفذ المدخل ورسم السائل في النظام قبل إزاحةه عبر منفذ المخرج. تسمح هذه الآلية بنقل السوائل الفعال والموثوق به ، مما يجعل مضخات التروس مكونًا حيويًا في التطبيقات الصناعية المختلفة.

لماذا مضخات التروس الداخلية مهمة

أهمية مضخات التروس الداخلية يكمن في تعدد استخداماتها واستخدامها على نطاق واسع عبر الصناعات المختلفة. تلعب هذه المضخات دورًا مهمًا في ضمان العمليات السلسة في التطبيقات مثل أنظمة توجيه الطاقة الهيدروليكية وأنظمة التشحيم وأنظمة توصيل الوقود. قدرتهم على التعامل مع سوائل اللزوجة العالية بسهولة تجعلها لا غنى عنها في العديد من العمليات اليومية.

يستمر الطلب على مضخات التروس الداخلية في الارتفاع بسبب كفاءتها وموثوقيتها وقدرتها على التكيف عبر القطاعات الصناعية المتنوعة. على هذا النحو ، يصبح فهم تعقيدات مضخات التروس الداخلية أمرًا ضروريًا للشركات التي تتطلع إلى تحسين عمليات معالجة السوائل الخاصة بها.

1. أساسيات مضخات التروس

تعد مضخات التروس الداخلية مكونًا أساسيًا في مختلف التطبيقات الصناعية ، مما يوفر طريقة موثوقة وفعالة لنقل السوائل. إن فهم كيفية عمل هذه المضخات ومزاياها وعيوبها أمر بالغ الأهمية للشركات التي تتطلع إلى تحسين عمليات معالجة السوائل.

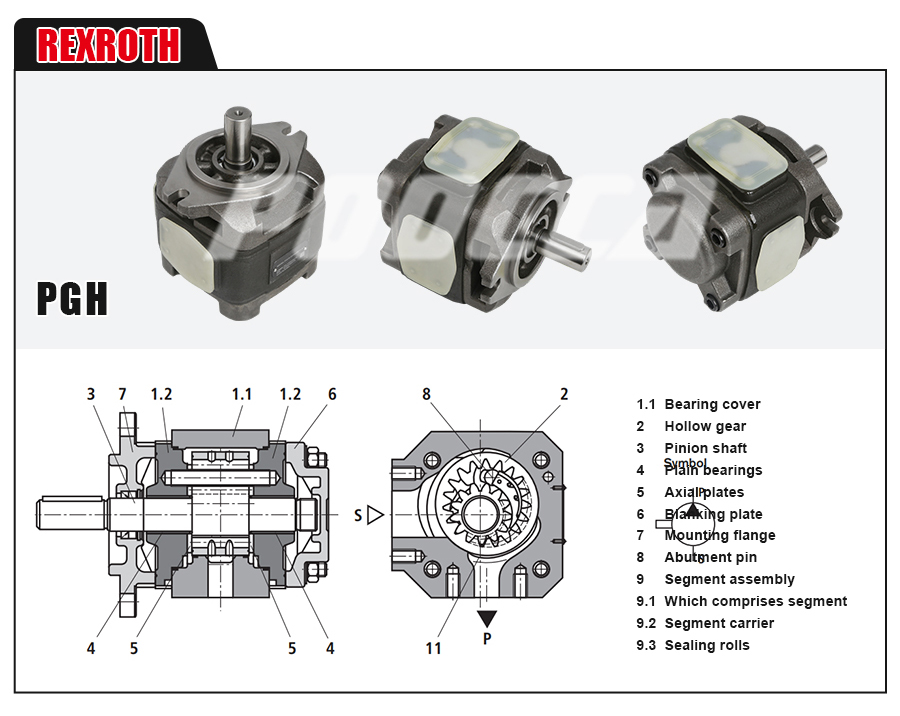

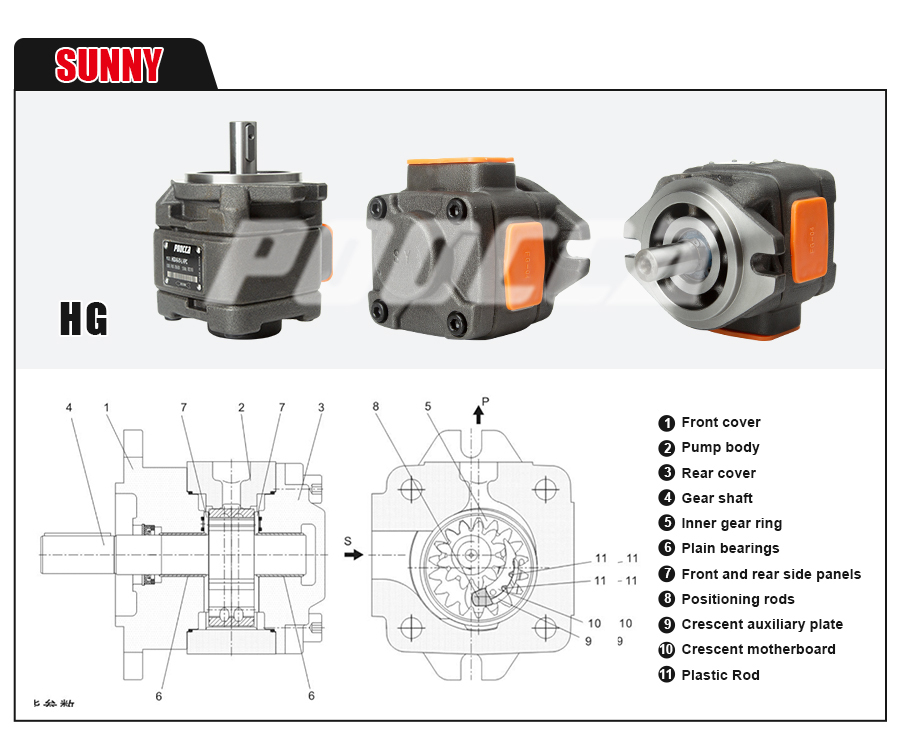

كيف تعمل مضخات التروس الداخلية

تشغيل مضخات التروس الداخلية يعتمد على تفاعل تروس الدوران داخل سكن محكم. مع تدوير التروس ، فإنها تخلق غرفًا بين الأسنان ، والتي تصيد السائل وتحريكه بشكل فعال من المدخل إلى منفذ المضخة. تؤدي هذه الآلية إلى تدفق مستمر وسلس للسائل ، مما يجعل مضخات التروس الداخلية مناسبة جيدًا للتطبيقات التي تتطلب توصيلًا دقيقًا ومتسقًا للسوائل. يوفر تصميم مضخات التروس الداخلية أيضًا إمكانيات شفط أفضل ، خاصة بالنسبة للزوجة العالية والسوائل الحساسة للقص ، مما يجعلها خيارًا مثاليًا للتعامل مع السوائل الصعبة.

مزايا وعيوب

لماذا تختار مضخة ترس داخلية

واحدة من المزايا الأساسية مضخات التروس هي قدرتها على التعامل مع سوائل اللزوجة العالية بسهولة ، مما يجعلها مناسبة لمجموعة واسعة من العمليات الصناعية. بالإضافة إلى ذلك ، توفر مضخات التروس الداخلية إمكانيات شفط أفضل مقارنةً بأنواع أخرى من المضخات ، مما يسمح لها بنقل السوائل بكفاءة مع لزوجة متفاوتة. ومع ذلك ، من المهم الإشارة إلى أنه مع انخفاض اللزوجة السائلة ، قد تصبح مضخات التروس الداخلية أقل كفاءة بسبب انخفاض التشحيم بين التروس.

على الرغم من مزاياها العديدة ، تأتي مضخات التروس الداخلية أيضًا مع بعض القيود. وتشمل هذه التحديات المحتملة في التعامل مع السوائل الكاشطة أو التآكل ، وكذلك الحاجة إلى صيانة منتظمة لضمان الأداء الأمثل. من الضروري للشركات تقييم هذه العوامل بعناية عند النظر في استخدام مضخات التروس الداخلية في عملياتها.

2. الميزات الرئيسية لمضخات التروس الداخلية

تمتلك مضخات التروس الداخلية ميزات فريدة تجعلها مناسبة تمامًا لمجموعة واسعة من التطبيقات الصناعية. يعد فهم الجوانب الرئيسية للضغط والتدفق ، وكذلك أهمية حجم المضخة ، أمرًا ضروريًا للشركات التي تسعى إلى تحسين عمليات معالجة السوائل.

فهم الضغط والتدفق

مضخات التروس الداخلية تشتهر بأدائها الاستثنائي في التعامل مع سوائل اللزوجة العالية. على عكس مضخات التروس الخارجية ، التي يمكن أن تحافظ على ضغوط أعلى من ما يصل إلى 7500 رطل / بوصة مربعة ، تتفوق مضخات التروس الداخلية في خلق إمكانات شفط أفضل وأكثر ملاءمة للسوائل ذات اللزوجة العالية وحساسية القص. تتيح هذه الخاصية الفريدة مضخات التروس الداخلية العمل في نطاق مفيد من 1CP إلى أكثر من 1،000،000 درجة مئوية ، مما يجعلها خيارًا مثاليًا للتطبيقات التي تتطلب نقل السوائل الفعال في ظل ظروف صعبة.

قدرة مضخات التروس الداخلية للحفاظ على معدلات التدفق المتسقة هي ميزة رئيسية أخرى تميزها. يقلل تصميم هذه المضخات من نبضات التدفق والضوضاء ، مما يوفر تدفقًا ناعمًا ومستمرًا للسائل. هذه الميزة مفيدة بشكل خاص في التطبيقات التي يكون فيها توصيل السوائل الدقيق أمرًا بالغ الأهمية ، مما يضمن أداءً موثوقًا به عبر مختلف العمليات الصناعية.

3. اختيار مضخة التروس الداخلية اليمنى

عندما يتعلق الأمر باختيار الحق مضخة التروس الداخلية، يجب النظر في العديد من المعايير الحاسمة لضمان الأداء الأمثل والكفاءة في عمليات معالجة السوائل. إن فهم العوامل الرئيسية التي تؤثر على اختيار المضخة ، وكذلك المزالق الشائعة التي يجب تجنبها ، أمر ضروري للشركات في مختلف الصناعات.

معايير اختيار المضخة

اكتب اعتبارات ختم العمود والحجم والعمود

الخطوة الأولى في اختيار مضخة التروس الداخلية يتم تحديد النوع المحدد الذي يناسب التطبيق المقصود. تم تصميم أنواع مختلفة من مضخات التروس الداخلية لاستيعاب اللزوجة السوائل المختلفة. على سبيل المثال ، تعد المضخات عالية السرعة مثالية لسوائل اللزوجة المنخفضة ، بينما توفر المضخات القياسية تنوعًا عبر مجموعة أوسع من اللزوجة.

بالإضافة إلى اعتبارات الكتابة ، يعد اختيار حجم المضخة المناسب أمرًا ضروريًا لتحقيق الأداء الأمثل. حجم مضخة التروس الداخلية يؤثر بشكل مباشر على معدل التدفق وقدرات الضغط. من الضروري مطابقة حجم المضخة مع متطلبات التدفق المتوقعة للتطبيق مع حساب الاختلافات المحتملة في لزوجة السوائل وظروف التشغيل. التحجيم المناسب يضمن نقل السوائل الفعال ويطيل عمر المضخة.

بالإضافة إلى ذلك ، يعد تقييم بدائل ختم العمود المحتملة أمرًا ضروريًا عندما يتعلق الأمر بتجنب التسرب والحفاظ على سلامة النظام. يتوقف اختيار ختم العمود المناسب على العديد من العوامل الرئيسية التي قد تتضمن التوافق مع السوائل ، ومتطلبات الضغط المحددة على وجه التحديد ، وكذلك الظروف البيئية السائدة.

التغلب على أخطاء الاختيار المشتركة

تجنب المزالق في عملية الاختيار

خطأ شائع واحد في اختيار مضخة التروس الداخلية يطل على أهمية فهم متطلبات التطبيق المحددة. الفشل في النظر في عوامل مثل لزوجة السوائل ، وتغيرات درجة الحرارة ، وضغط النظام يمكن أن يؤدي إلى أداء المضخة دون المستوى الأمثل والمشكلات التشغيلية المحتملة. للتغلب على هذا المزال ، يجب على الشركات إجراء تقييم شامل لاحتياجاتهم من معالجة السوائل وطلب التوجيه من المهنيين أو المهندسين ذوي الخبرة.

جانب آخر حاسم غالبًا ما يتم تجاهله هو إهمال اعتبارات الصيانة طويلة الأجل أثناء اختيار المضخة. على الرغم من أن مواصفات الأداء الأولية ضرورية ، إلا أنه من الأهمية بمكان تقييم متطلبات الصيانة مثل بدائل الختم وتفتيشات التروس وصيانة النظام بشكل عام. من خلال العوملة في احتياجات الصيانة على المدى الطويل في مرحلة الاختيار ، يمكن للشركات اتخاذ قرارات مستنيرة تساهم في العمليات المستدامة وممارسات الصيانة الفعالة من حيث التكلفة.

بوكا الهيدروليكيات هي مؤسسة هيدروليكية قوية تدمج البحث والتطوير والتصنيع والمبيعات والصيانة. يتم تصدير منتجاتها إلى أكثر من 120 دولة. جودتها وسعرها وخدمتها معترف بها بعمق وموثوق بها من قبل العملاء.

4. الحفاظ على مضخة التروس الداخلية الخاصة بك

مرة واحدة مضخة التروس الداخلية يتم تثبيته والتشغيل ، وصيانة الروتينية تصبح ضرورية لضمان طول العمر والكفاءة والأداء الموثوق. من خلال الالتزام بجدول صيانة شامل واتباع الإجراءات الموصى بها ، يمكن للشركات منع التآكل المبكرة والأضرار والانهيارات. بالإضافة إلى ذلك ، فإن استكشاف الأخطاء وإصلاحها في المشكلات الشائعة على الفور وتنفيذ الإصلاحات اللازمة سيؤدي إلى تقليل وقت التوقف إلى الحد الأدنى وتحسين أداء المضخة.

نصائح الصيانة الروتينية

الحفاظ على مضخة التروس الداخلية يتضمن العديد من الممارسات الرئيسية التي تسهم في صحتها ووظائفها العامة. أحد الأخطاء الشائعة التي لوحظت بين أطقم الصيانة هي ممارسة الصدمة بدء المضخة للتحقق من الدوران. على الرغم من طبيعتها الروتينية ، يمكن أن يكون هذا النهج ضارًا. لا يمكن لمضخات التروس الداخلية أن تعمل جافة ، ويمكن أن تؤدي بدء الدوران بدون منتج في المضخة إلى احتكاك قاس الدوار ، مما يسبب أضرارًا. كان هذا واضحًا في زيارة عميل حديثة ، حيث أسفرت مضخة ، عند بدء تشغيلها ، عن تندب على الغلاف. يمكن أن تؤدي البدايات الجافة أيضًا إلى وسط الأختام الميكانيكية. لتجنب مثل هذه المشكلات ، الامتناع عن بدء مضخات التروس الداخلية دون ضمان تزييت مناسب.

بالإضافة إلى هذا التدبير الاحترازي ، يعد الفحص المنتظم لمكونات المضخة أمرًا بالغ الأهمية لتحديد المشكلات المحتملة في وقت مبكر. ويشمل ذلك مراقبة التآكل ، والتحقق من التسريبات أو الضوضاء غير الطبيعية أثناء التشغيل ، وضمان مستويات التشحيم المناسبة. لا يمتد تنفيذ نهج استباقي للصيانة مدى عمر مضخة التروس الداخلية فحسب ، بل يقلل أيضًا من مخاطر الفشل غير المتوقع الذي يمكن أن يعطل العمليات.

استكشاف الأخطاء وإصلاحها القضايا المشتركة

عندما يتعلق الأمر لاستكشاف القضايا المشتركة مع مضخة التروس الداخلية، تحديد الفوري والقرار أمر بالغ الأهمية. بعض المشكلات السائدة تشمل تسرب السوائل في الأختام أو الاتصالات ، وانخفاض معدلات التدفق ، والضوضاء غير الطبيعية أثناء التشغيل ، وزيادة استهلاك الطاقة. يتطلب معالجة هذه المشكلات على الفور اتباع نهج منهجي يتضمن فحص جميع المكونات ذات الصلة بدقة.

تتضمن إحدى طرق استكشاف الأخطاء وإصلاحها فعالة إجراء تحليل مفصل لظروف تشغيل النظام ومعلمات الأداء. من خلال مراقبة مستويات الضغط ، ومعدلات التدفق ، والتغيرات في درجة الحرارة ، وسلوك النظام العام أثناء التشغيل ، يمكن لأطقم الصيانة تحديد المخالفات المحتملة واتخاذ الإجراءات التصحيحية حسب الحاجة.

علاوة على ذلك ، يمكن أن يوفر التعاون مع المهنيين أو المهندسين ذوي الخبرة لسيناريوهات استكشاف الأخطاء وإصلاحها معقدة رؤى قيمة في حل المشكلات المعقدة بفعالية. يمكن أن تساعد خبراتهم الشركات على التنقل في مهام الصيانة الصعبة مع ضمان الأداء الأمثل من مضخات التروس الداخلية.

من خلال إعطاء الأولوية لممارسات الصيانة الروتينية وجهود استكشاف الأخطاء وإصلاحها الاستباقية ، يمكن للشركات أن تدعم موثوقية وكفاءة مضخات التروس الداخلية مع تقليل الاضطرابات التشغيلية.