Understanding the Function of Pressure Relief Valves in Hydraulic Systems

Why Are Pressure Relief Valves Critical?

Pressure relief valves are vital for keeping hydraulic systems safe and smooth. Their main job, the function of pressure relief valve in hydraulic system, stops pressure from soaring too high. Excess pressure might wreck gear or cause harm. By managing pressure, these valves shield workers and machines. Plus, they keep systems running well. They hold pressure in the sweet spot. This lets hydraulic parts shine at their best. When pressure climbs past a set point, the valve opens. It lets out extra force. This guards the system from risky overloads.

Key Applications of Hydraulic Pressure Relief Valves

Hydraulic pressure relief valves pop up in many fields. You see them in making, building, farming, and car industries. In factory tools, they keep pressure safe for presses and fluid-driven machines. In building rigs like diggers and dozers, they save key parts. They stop breakdowns during heavy tasks. Likewise, in farm gear, they ensure steady work. They keep hydraulic setups at the right pressure. This is crucial for smooth operation.

How Does a Hydraulic Pressure Relief Valve Work?

Basic Operating Mechanism

A spring-powered setup drives how does a hydraulic pressure relief valve work. The valve opens when pressure tops the set limit. Fluid flows through and pushes the valve poppet. This overcomes the spring’s push. As a result, the valve opens. Excess fluid escapes. This drops the system’s pressure. When pressure falls below the mark, the spring nudges the poppet back. The valve shuts. Normal flow resumes.

Hydraulic Pilot-Operated Pressure Relief Valves Explained

A hydraulic pilot operated pressure relief valve steps up for tricky high-pressure jobs. Unlike simple spring-only valves, these use a bonus control setup. This tweak gives finer pressure handling. A tiny pilot valve steers the bigger relief valve. This duo runs smoothly. It offers sharp control in high-pressure setups. So, it’s perfect for tasks with shifting loads or complex fluid systems.

How to Adjust Hydraulic Pressure Relief Valves: Step-by-Step Guide

Tools Required for Safe Adjustment

To tweak how to adjust hydraulic pressure relief valves, grab some gear. You need pressure gauges first. They’re key for watching system pressure while you adjust. Wrenches or socket kits help too. They tighten or loosen the adjustment screw. Safety stuff matters as well. Wear gloves and goggles. These guard against sudden pressure bursts or fluid spills.

Adjusting the Pressure Setting

Adjusting the pressure takes a few easy steps. Start by finding the adjustment screw or knob. It’s usually marked clearly. Next, watch the pressure gauge. Slowly turn the screw. Clockwise hikes the pressure. Counterclockwise lowers it. Keep an eye on the gauge. Ensure the setting fits the needed range. Once it’s right, lock the screw tight. Then, recheck the system. Make tiny tweaks and test often. This avoids wild pressure swings.

Common Mistakes to Avoid

A frequent slip-up is over-tightening the screw. This can mess up settings or harm the valve. Also, stick to the maker’s rules. Ignoring them risks wrong pressure levels. That could hurt the system. Skipping calibration is another goof. It’s vital to confirm the valve works right.

How to Install a Hydraulic Pressure Relief Valve Correctly

Pre-Installation Checks

Before you dive into how to install a hydraulic pressure relief valve, do some prep. Check if the valve fits your setup. Look at its pressure range and flow rate. Ensure they match your needs. Inspect ports and threads too. Any dents might spark leaks or bad fits.

Installation Process

Setup begins with mounting the valve firm in the hydraulic loop. Place it right to avoid wonky alignment during use. Hook up the inlet and outlet ports per the flow plan. Then, peek for leaks at the joins. A snug fit is a must. After setup, test the system’s reaction to pressure shifts. Confirm it works as hoped.

How to Test Hydraulic Pressure Relief Valves for Optimal Performance

Simple Testing Methods

Checking how to test hydraulic pressure relief valve keeps it running well. A quick trick uses a pressure gauge. Hook it to the system. Crank up the pressure. Watch how the valve acts when pressure tops the limit. It should open and dump extra force. This brings the system back to normal. If it doesn’t kick in right or acts odd, it might need fixing or swapping.

Signs of a Faulty Valve

Spotting a dud valve is key. Wild pressure jumps signal trouble. The valve might not hold steady pressure. Leaks near it or failure to reset after dumping pressure hint at issues too. A sticky valve or worn bits can flop. This leads to sluggish systems or damage. Regular checks catch these snags early.

Hydraulic Pilot-Operated Pressure Relief Valves: Advanced Insights

Benefits of Pilot-Operated Designs

Hydraulic pilot operated pressure relief valves outshine basic spring designs. They offer pinpoint pressure control. This ensures slick running in tricky setups. A pilot valve guides the relief valve. This cuts pressure spikes even at high levels. So, they suit tasks with big load swings or where tight pressure control is a must.

Maintenance Best Practices

Keeping a hydraulic pilot operated pressure relief valve tip-top needs routine care. Clean the pilot lines to dodge clogs. Check seals for wear too. Swap out any beat-up parts. Steady upkeep keeps it humming. It stops pricey fixes and downtime in high-pressure rigs.

Frequently Asked Questions About Pressure Relief Valves

Can I Use a Generic Valve for My Hydraulic System?

A generic valve might tempt you. But it’s critical to match its specs to your setup. A wrong fit can spark pressure woes, sluggishness, or even breakdowns. Custom valves bring surer fixes. They sync perfectly with your hydraulic gear.

How Often Should Pressure Relief Valves Be Tested?

Test pressure relief valves often to keep them sharp. How often depends on use and field rules. Heavy-duty setups might need frequent checks. Lighter tasks can stick to regular upkeep schedules.

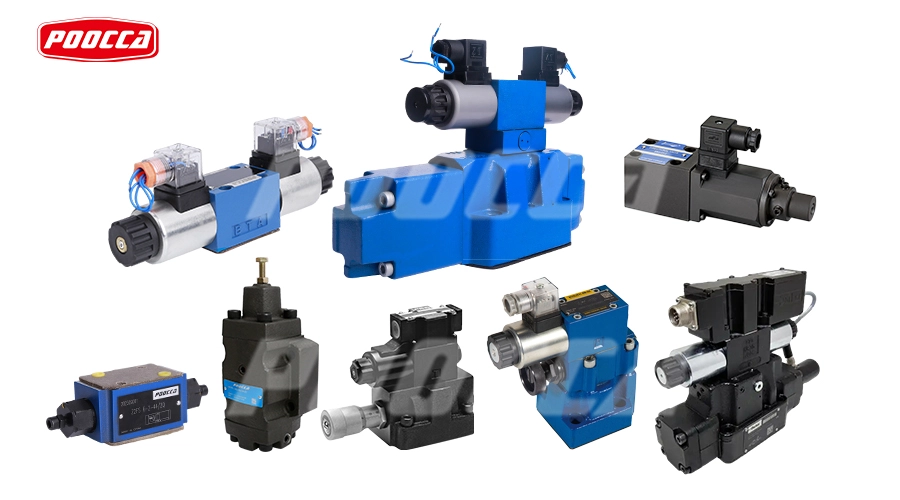

Why Choose Poocca Hydraulic Pressure Relief Valve Customization Service?

Tailored Solutions for Unique Needs

Poocca boasts over 20 years crafting valves. They shape hydraulic pressure relief valves to fit your setup’s quirks. Need special flow rates, pressure bands, or port setups? Poocca’s pros whip up a fix that slots in just right.

Quality Assurance & Fast Delivery

Poocca guarantees top-notch making. They slap a 12-month promise on all valves. Quick shipping and factory-direct prices come too. Globally, they keep your systems purring with trusty fixes.

Conclusion & Next Steps

To wrap up, hydraulic pressure relief valves are must-haves. They guard safety and smoothness in hydraulic setups. Knowing their function of pressure relief valve in hydraulic system, plus how to adjust, install, and test them, boosts performance. For custom fixes, Poocca serves up expert design to match your needs.

Need a solid pressure relief valve for your rig?

Reach Poocca’s pros today for a FREE chat on tailored hydraulic answers!