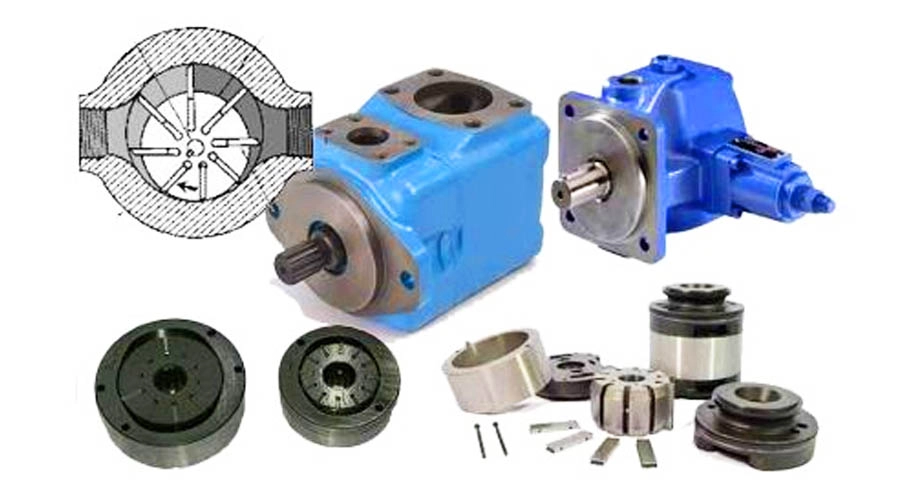

What Is a Hydraulic Vane Pump?

A hydraulic vane pump is a kind of positive displacement pump. It’s used a lot in water systems to move liquid smoothly. It has a casing, a rotor, and blades that slide into slots in the rotor. As the rotor spins, these blades stay in contact with the casing’s inner surface. This forms spaces that grow and shrink to move liquid. Hydraulic vane pumps are known for their great efficiency. They run smoothly. They can handle different liquid thicknesses. You’ll find them in car power steering, factory machines, and mobile gear.

How Does a Hydraulic Vane Pump Work?

A hydraulic vane pump works in three main steps: suction, compression, and discharge.

The Suction Phase in Operation

In this step, the rotor spins inside the pump casing. The blades are pushed out by spinning force or water pressure. This creates sealed spaces between them. When these spaces pass the suction port, they get bigger. This growth makes a vacuum. The vacuum pulls liquid into the pump. This ensures the pump gets enough liquid for the next steps.

The Compression Phase Explained

As the rotor keeps spinning, the spaces move away from the suction port. The blades stay in contact with the casing’s inner surface. They trap liquid in these spaces. As the spaces near the discharge port, they shrink. This squeezes the trapped liquid. This step is key. It builds pressure in the system.

The Discharge Phase Process

In the final step, the squeezed spaces reach the discharge port. The pressurized liquid is pushed out of the pump. The spaces get smaller. The rotor’s steady spinning keeps liquid flowing smoothly through the system. This repeating process gives consistent performance. It also maintains steady pressure in water systems.

Types of Hydraulic Vane Pumps

Hydraulic vane pumps come in different types. They meet various needs for different jobs.

Fixed Displacement Vane Pumps

Fixed displacement vane pumps give a steady flow rate. This happens no matter the system pressure. They are built to deliver a set amount of liquid per cycle. They’re perfect for jobs needing constant flow. You’ll see them in factory machines and car systems that need reliable performance.

Variable Displacement Vane Pumps

Variable displacement vane pumps can change their flow rate. They adjust based on system pressure and need. This is done by changing the pump’s inner shape or rotor angle. These pumps are great for jobs with changing demands. Examples include mobile gear or machines with varying tasks.

Single-Stage Vane Pumps

Single-stage vane pumps have one rotor and blade set. Their simple design ensures steady performance. They have fewer moving parts. This makes them easy to care for. They work well for medium-pressure jobs like oil systems or water power units.

Multi-Stage Vane Pumps

Multi-stage vane pumps have several rotor and blade sets. They create higher pressures and flow rates. They do this through multiple squeezing stages. Each stage boosts output pressure a bit more. These pumps shine in high-pressure settings like water presses or heavy factory machines.

Advantages of Using Hydraulic Vane Pumps

Hydraulic vane pumps are vital in water systems. They offer many benefits. These make them essential for various jobs. Their design and smooth operation add to their popularity across fields.

High Efficiency and Performance

Hydraulic vane pumps have great liquid-moving efficiency. They can shift large amounts of liquid with little energy waste. This saves money. It also boosts system performance. Their smooth operation keeps pressure steady. This is crucial for systems needing exact control.

Low Noise Levels

Hydraulic vane pumps run quietly. Their balanced design and steady liquid flow reduce noise. This makes them good for places where quiet is important. Examples include hospitals or office buildings. This feature improves workplace comfort. It also meets noise rules in sensitive areas.

Versatility Across Applications

These pumps are very flexible. They can handle many liquid thicknesses. They work well with different water liquids. This adaptability lets them be used in many jobs. These range from car power steering to heavy factory machines.

Longevity and Reliability

Hydraulic vane pumps are tough. Their self-adjusting blades keep performance steady over time. This ensures a long working life. It also makes them dependable. Their toughness cuts the need for replacements and upkeep. This lowers running costs.

Ease of Maintenance

Upkeep is simple with hydraulic vane pumps. Their cartridge design allows quick part swaps. You don’t need to take the whole pump apart. This cuts downtime and repair costs. Easy access to parts makes fixes quick.

Compact Design for Space Efficiency

Hydraulic vane pumps have a small design. This makes them perfect for jobs with limited space. They deliver strong performance without taking up much room. This adds to their appeal in modern machine designs.

Selecting the Right Hydraulic Vane Pump from POOCCA

Choosing the best hydraulic vane pump needs careful thought. You must consider system needs and specific job requirements. POOCCA offers a wide range of hydraulic vane pumps. They are designed to meet various demands.

Understanding POOCCA’s Expertise

POOCCA started in 2006. They have over 20 years in the water industry. Their facilities cover over 8,000 square meters. They use advanced tools like CNC gear grinders and measuring machines. POOCCA is a leader in water solutions. Their skills cover fields like building, farming, metalwork, and more.

Diverse Product Offerings

POOCCA provides many hydraulic vane pumps. They suit different jobs. You can choose fixed or variable displacement models. They offer single-stage or multi-stage designs. POOCCA’s products ensure compatibility with many work needs. They maintain high efficiency and dependability.

Customization Services

POOCCA offers more than standard products. They provide tailored solutions. Their team creates custom designs to meet unique client needs. They handle everything from product design to packaging. Every detail aligns with customer wishes.

Technical Support and After-Sales Service

POOCCA’s strong support system stands out. They offer pre-sale technical advice. This helps clients pick the right pump for their job. After purchase, they provide warranty services and repair help. They also have feedback systems to fix issues quickly.

Commitment to Quality Assurance

Quality is key at POOCCA. All products go through tough testing. They use advanced tools like CAT computer-controlled testing machines. This ensures every pump meets industry standards for performance and toughness.

Global Reach and Partnerships

POOCCA exports to over 100 countries. They have partners in more than 75 nations. These include the United States, Indonesia, Mexico, Thailand, Russia, and Brazil. Their ability to meet global demands shows their flexibility and dependability worldwide.

Choosing a hydraulic vane pump from POOCCA means investing in quality. It also means getting new ideas and great customer care. Their wide product range and technical skills ensure you find the perfect solution for your water system needs.